Burner

A burner and combustion head technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low combustion efficiency, insufficient combustion, high pollutant emissions, etc., to improve combustion efficiency, reduce CO and NOx content, environmental friendliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

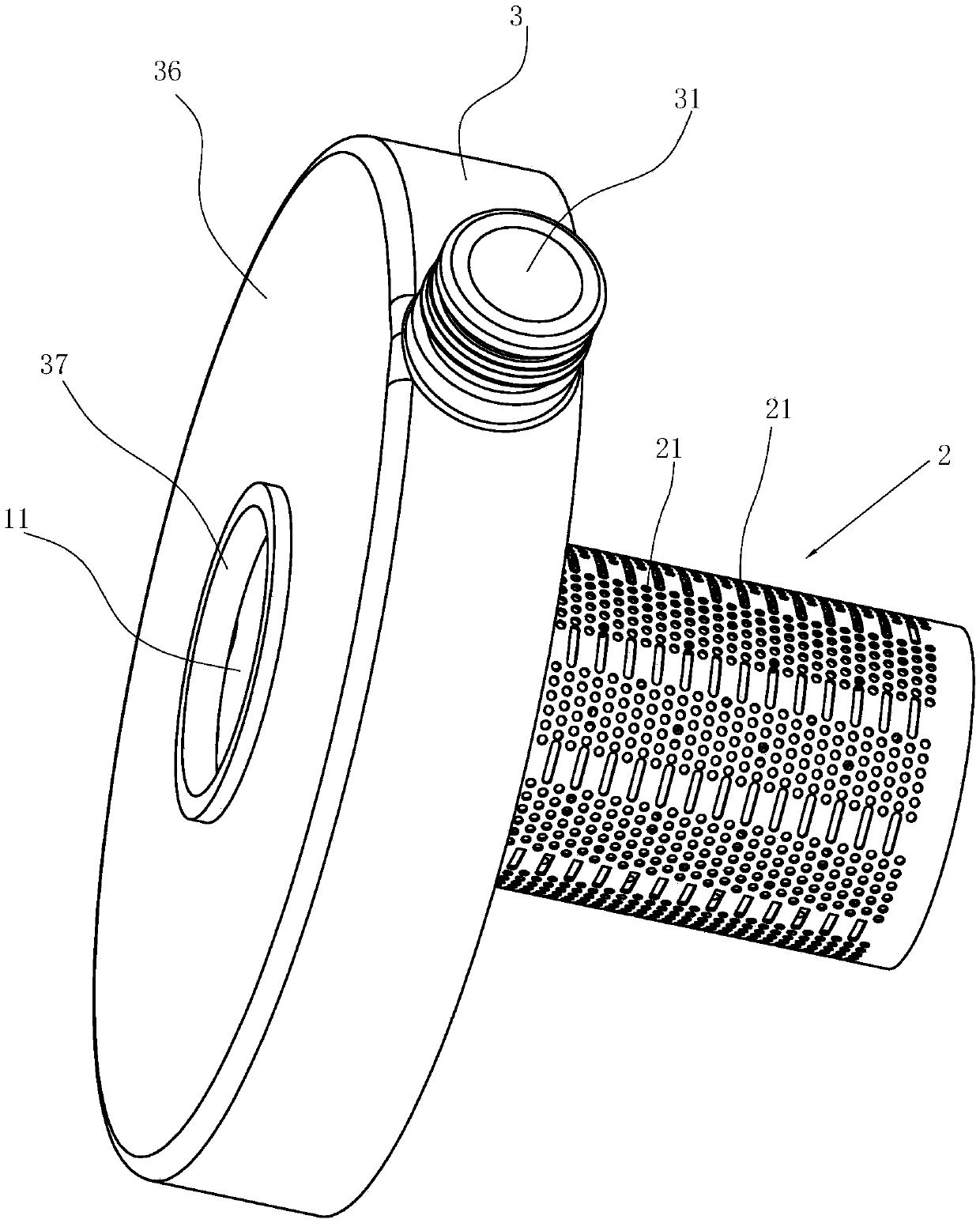

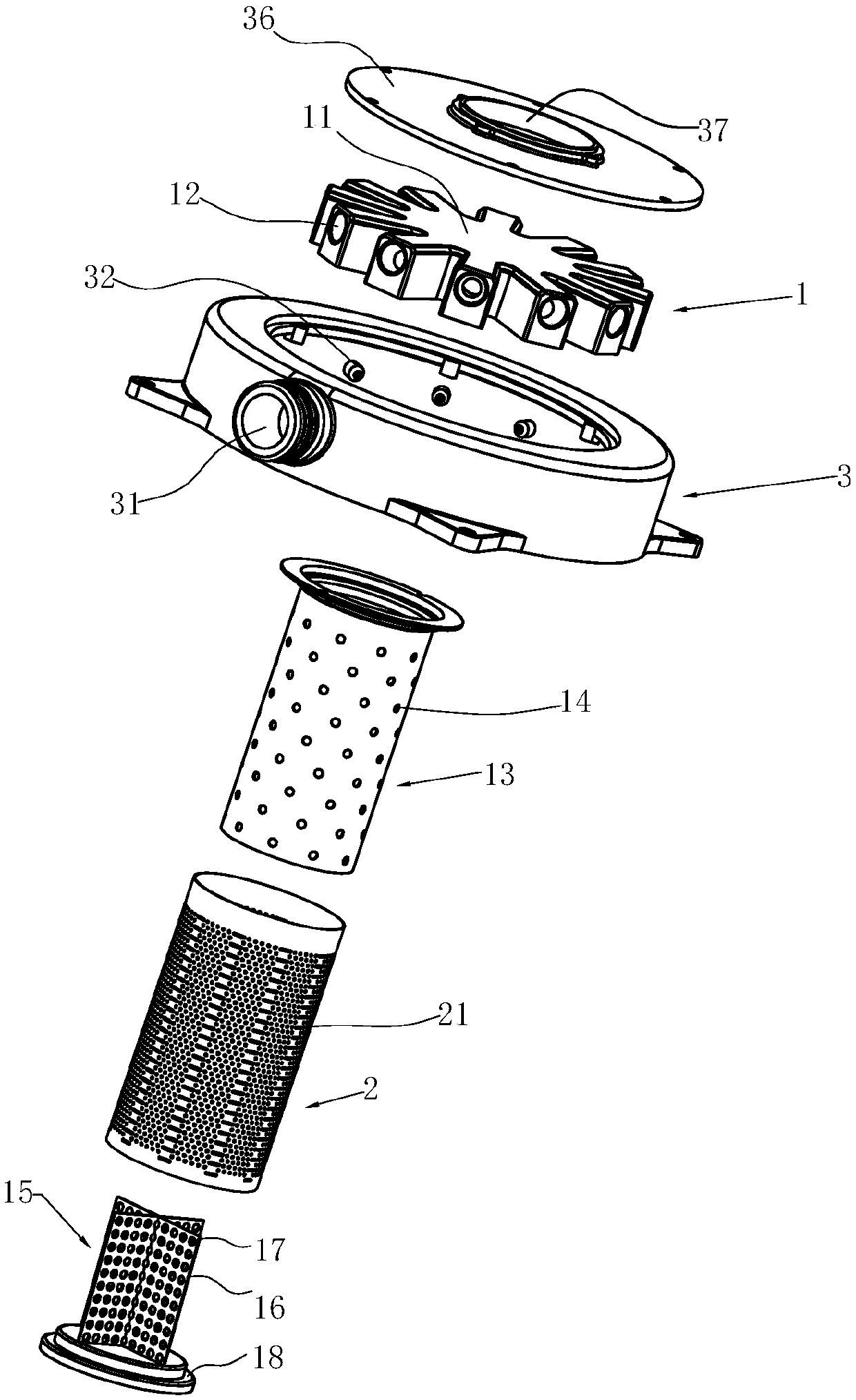

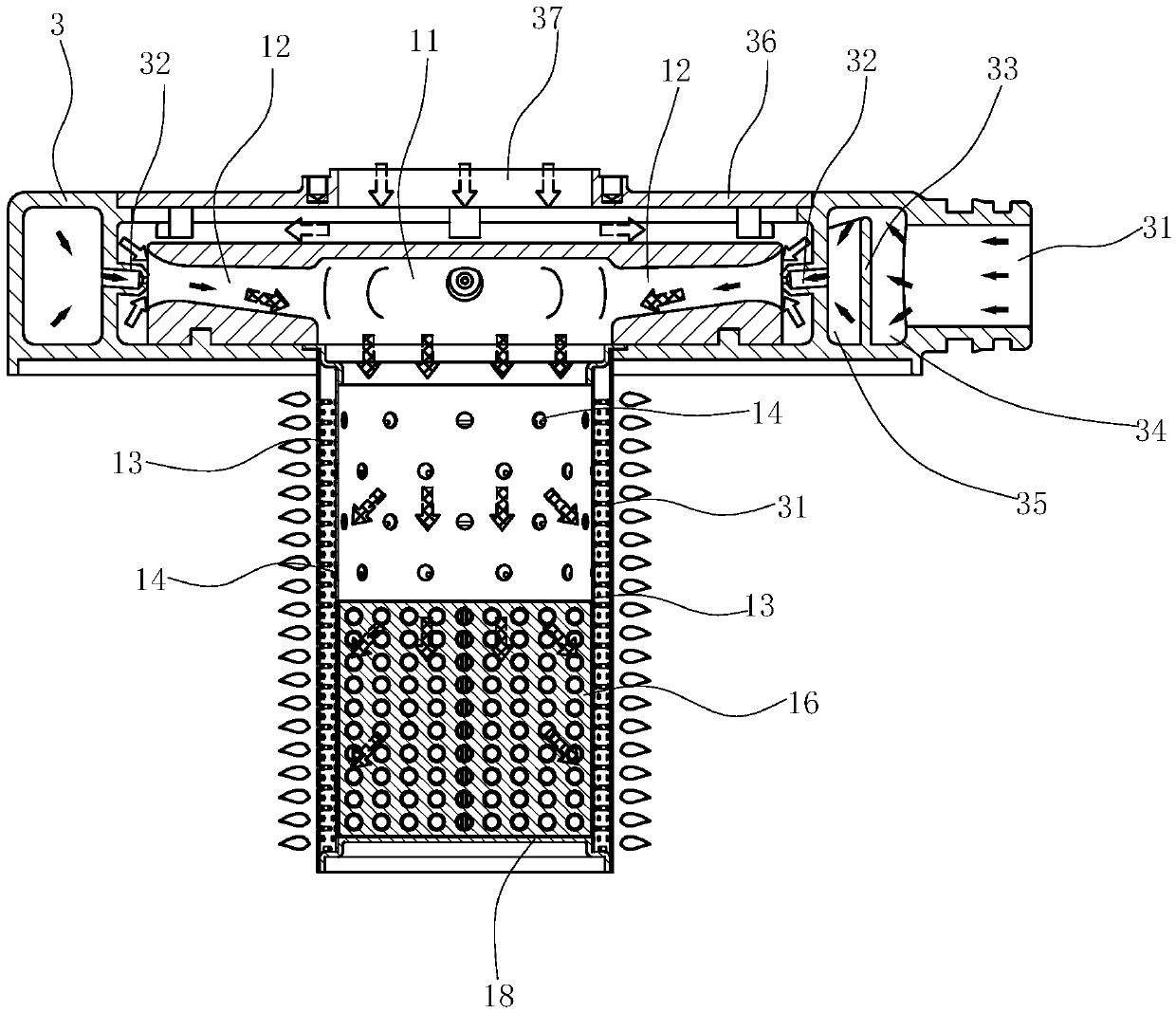

[0030] Such as Figure 1 to Figure 4 As shown, the burner includes:

[0031] The gas distribution pipe 3 is connected to the gas source, redistributes the gas and sends it into the injection pipe, which is a sealed annular sleeve, and a plurality of nozzles 32 connected to the inner cavity of the gas distribution pipe are arranged at intervals on the inner peripheral wall of the annular sleeve A gas inlet 31 connecting the gas source and the inner cavity of the gas distribution pipe is provided on the outer peripheral wall of the sleeve, and a first gas distributor 33 is provided in the inner cavity of the sleeve corresponding to the gas inlet 31 .

[0032] The first gas distributor 33 is used to redistribute the gas entering the gas distribution pipe, so as to avoid gas short circuit and directly enter the injection channel near the gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com