Preparation method and application of polymer-based solid electrolyte

A solid-state electrolyte and polymer technology, which is used in composite electrolytes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of increased polarization current and low cost, and achieves reduced cracks, low cost, and improved surface morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a polymer-based solid electrolyte, comprising the following steps:

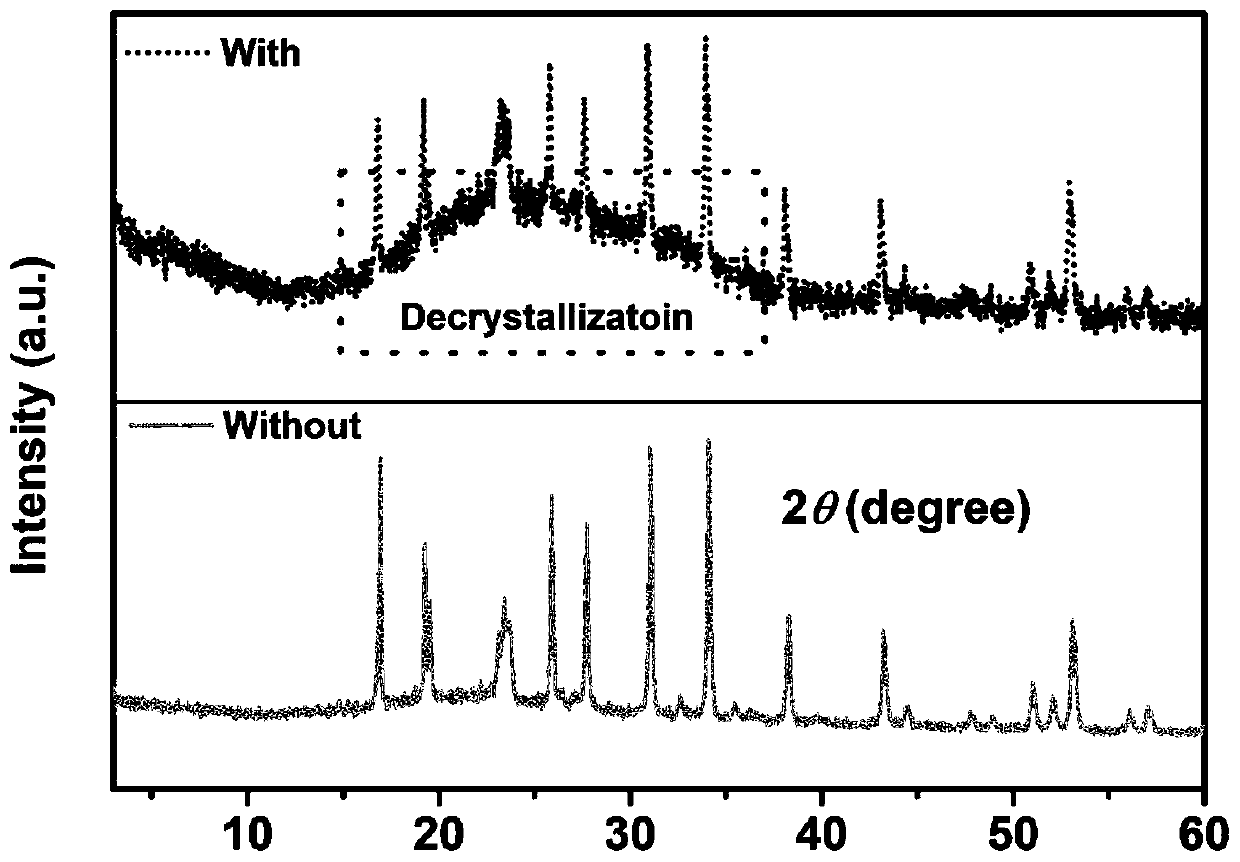

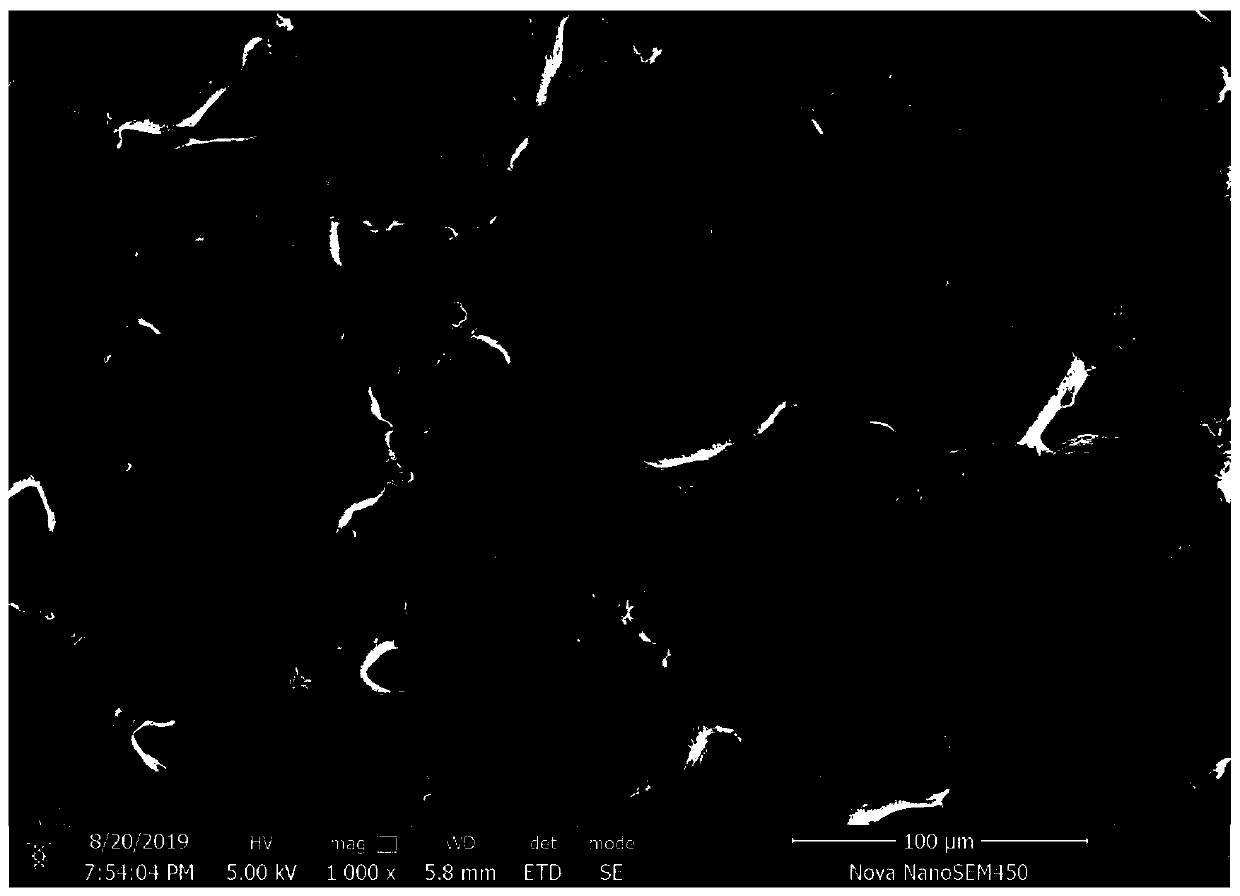

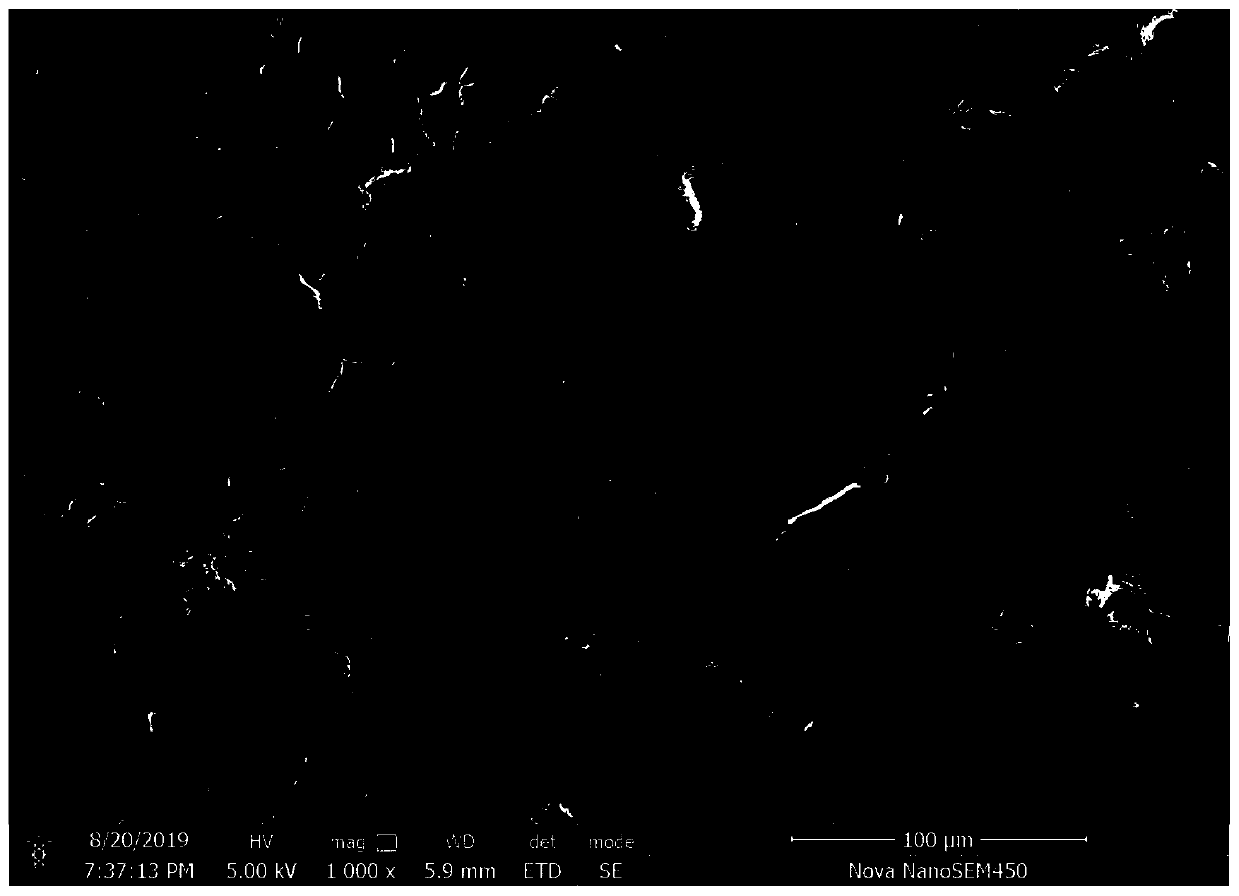

[0036] Step 1: Mix 1g polyethylene oxide (PEO), 500mg Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Powder (LLZTO) and 300mg lithium bistrifluoromethanesulfonimide (LiTFSI) were added to 10ml acetonitrile and stirred at 70°C for 12 hours to make the electrolyte a milky white gel.

[0037] Step 2: Add 20 mg of montmorillonite (MMT) into the solid electrolyte obtained in Step 1, and stir evenly.

[0038] Step 3: Use a dropper to evenly distribute the gel-like substance obtained in Step 2 on the polytetrafluoroethylene film, put it in an oven, and dry it at 70° C. for 12 hours to form a flexible solid electrolyte film.

Embodiment 2

[0040] According to the preparation method of the solid electrolyte in Example 1, only the montmorillonite in the preparation step 2 of the solid electrolyte was adjusted to 50 mg of tungsten disulfide, and the other steps remained unchanged.

Embodiment 3

[0042] According to the preparation method of the solid electrolyte in Example 1, only the montmorillonite in the preparation step 2 of the solid electrolyte was adjusted to 50 mg of molybdenum disulfide, and other steps remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com