Process for obtaining activated carbon by physical activation method

A technology of physical activation and activated carbon, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low activation temperature, short activation time, environmental hazards of waste water and waste gas, etc., achieve simple synthesis process, improve preparation efficiency, The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

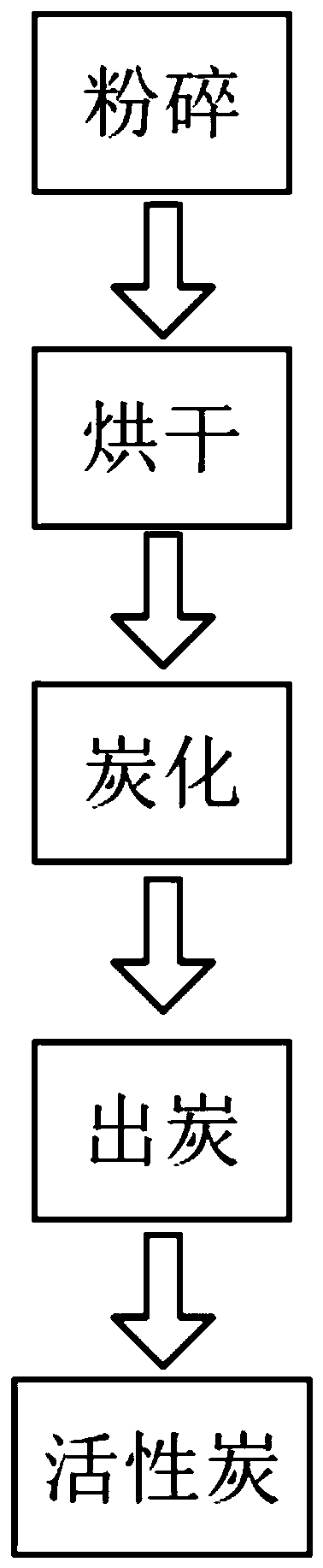

[0036] combine figure 1 , a kind of technique that physical activation method obtains activated carbon, comprises the steps:

[0037] S1, crushing: the wood is torn and crushed into sawdust by the crusher 1;

[0038] S2. Drying: The crushed sawdust is sent to the drying furnace 3 through the conveyor 2, the drying temperature is 200°C-250°C, the drying time is 15-30min, and the moisture content of the dried sawdust is 15-20 %;

[0039] S3. Carbonization: Send the dried sawdust into the carbonization device 4, and heat the carbonization device 4 through the combustion system 5. The temperature of the carbonization device 4 is 560°C to 750°C, and the carbonization time is 20 to 30 minutes to form charcoal;

[0040] S4. Charcoal production: the charcoal is cooled, and the water-cooled spiral is used for four-stage cooling, and the charcoal is pulverized into charcoal powder after sufficient cooling;

[0041] S5. Preparation of activated carbon: put the carbon powder in the phy...

Embodiment 2

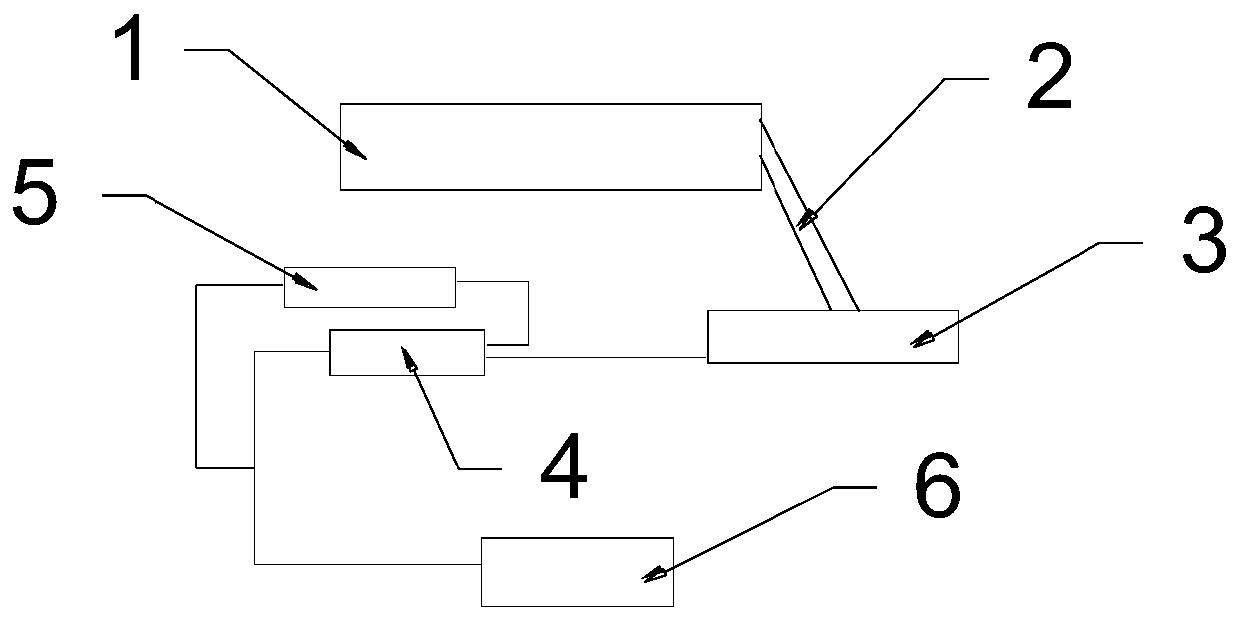

[0043] combine figure 2 and image 3 , a system for preparing activated carbon, comprising a pulverizer 1, a conveyor belt 2, a drying furnace 3, a carbonization device 4, a combustion device 5 and a physical activation device 6, the pulverizer 1, a conveyor belt 2, a drying furnace 3, The carbonization device 4 is connected with the physical activation device 6 in turn, and the combustion device 5 is connected with the drying furnace 3, the carbonization device 4 and the physical activation device 6, and the carbonization device 4 is sent into the carbon powder in the physical activation device 6, and the combustion The system 5 delivers water vapor into the physical activation device 6 .

[0044] The carbonization device 4 includes a carbonization furnace 41 and an insulating brick wall 42 wrapped outside the carbonization furnace 41 , and there is a cavity 43 between the carbonization furnace 41 and the insulating brick wall.

[0045] The combustion system 5 includes a c...

Embodiment 3

[0049] Such as Figure 4As shown, in combination with step S1, crushing: the wood is torn and crushed into sawdust by the shredder 1, and the wood is transported from the raw material storage area to the twin-shaft shredder 101, the twin-shaft shredder 102 and the pair of rollers respectively through belt transport. The pulverizer 103 pulverizes, and the pulverized sawdust is stored in the pulverized storage area for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com