Iron filings surface modifier and method for preparing alpha-Fe<(1-x)>Cr<x>OOH active layer

A surface modifier and surface modification technology, applied in catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high content, increased treatment units, and poor adhesion of surface substances , to achieve the effect of simple preparation method, good engineering applicability and good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0041] The effect of iron shavings (or iron filings) on catalytic ozone treatment of wastewater based on different modification conditions. Measure effluent TOC, total iron, hexavalent chromium content. Among them, water sample 1 is simulated wastewater sodium benzoate (100mg / L), and water sample 2 is a chemical wastewater SBR biochemical effluent.

[0042] Adopt iron filings surface modifier and modification method described in the present invention to modify iron filings, the steps are as follows:

[0043] Step 1: Wash with detergent several times, then soak in 1mol / L sodium hydroxide solution for 2 hours, and rinse with water; before oxidation modification, soak with 1% hydrochloric acid for 1 hour, and then rinse with water;

[0044] Step 2: Prepare iron filings surface modifier (the formula of each component is as described in Table 1), use the prepared modifier to coat the sample, and wait for the surface of the sample to dry; after the treatment is completed, wash it w...

Embodiment 9

[0066] A surface modifier for iron filings, comprising the following components in percentage parts:

[0067]

[0068]

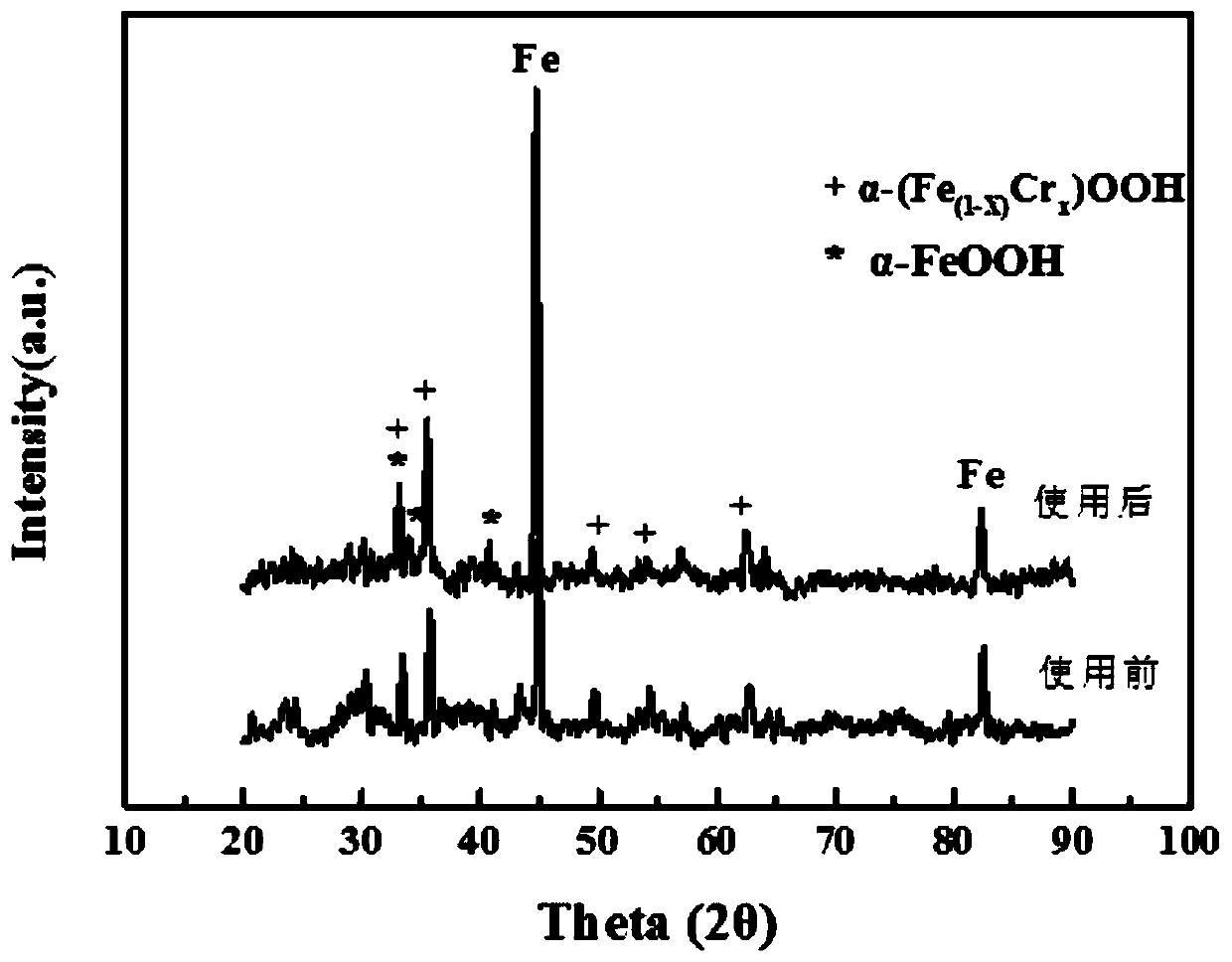

[0069] Preparation of α-Fe by using the above-mentioned iron filings surface modifier (1-x) Cr x The method for OOH active layer, this method comprises the following steps:

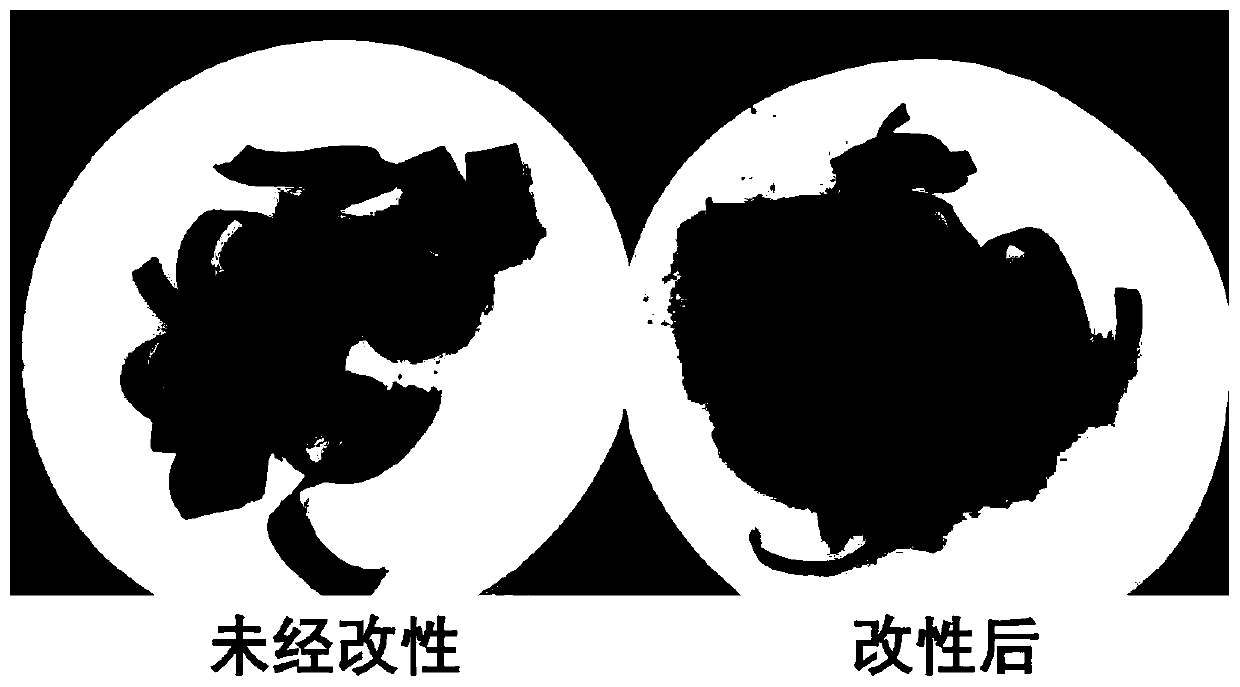

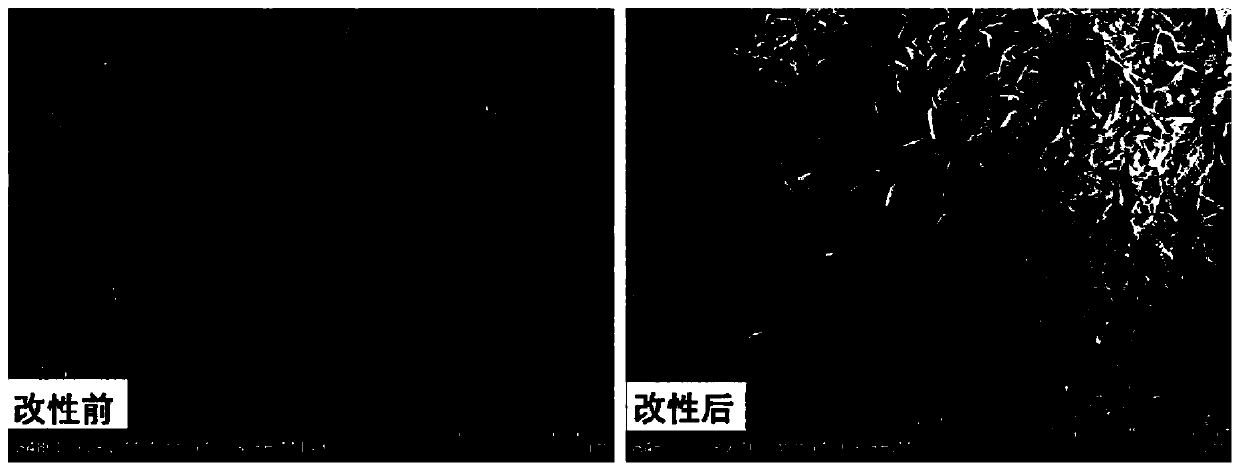

[0070] (1) Select scrap iron filings from low-carbon steel, medium-carbon steel, and low-alloy structural steel through drilling, planing, and milling processes. First, the industrial iron filings are washed several times with detergent to remove the outer layer of oil; then soaked in a sodium hydroxide solution with a concentration of 0.5mol / L for 1 hour to remove the oil stains tightly adsorbed on the surface; finally, the iron filings are repeatedly cleaned with deionized water. Chips to wash water is neutral;

[0071] (2) The iron filings after degreasing and cleaning are soaked in 0.5% hydrochloric acid for 1 hour before surface modification, and then rinsed with water. A...

Embodiment 10

[0075] A surface modifier for iron filings, comprising the following components in mass percent:

[0076]

[0077] Preparation of α-Fe by using the above-mentioned iron filings surface modifier (1-x) Cr x The method for OOH active layer, this method comprises the following steps:

[0078] (1) Select scrap iron filings from low-carbon steel, medium-carbon steel, and low-alloy structural steel through drilling, planing, and milling processes. First, wash the industrial iron filings with detergent several times to remove the outer layer of oil; then soak in a sodium hydroxide solution with a concentration of 2mol / L for 2 hours to remove the oil stains tightly adsorbed on the surface, and finally clean the iron filings repeatedly with deionized water until the washing water is neutral;

[0079] (2) The iron filings after degreasing and cleaning are soaked in 2% hydrochloric acid for 2 hours before surface modification, and then rinsed with water. At room temperature, spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com