Conductive film and preparation method thereof, heatable mica plate and manufacturing method thereof

A conductive film, mica board technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of unsuitable industrial production, endangerment, and cannot be used as area, etc., and achieves high power, small area, and heat generation. high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

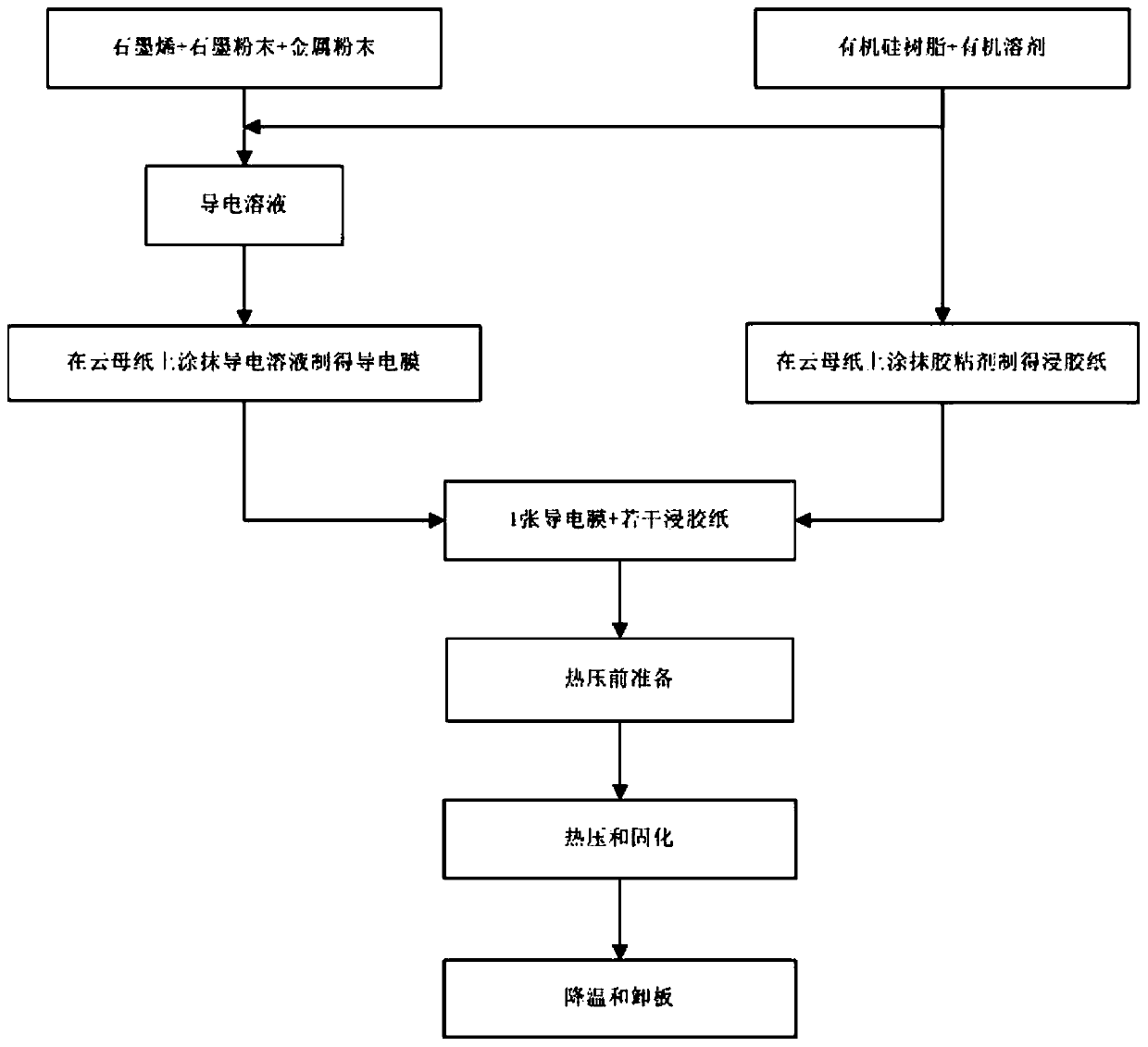

[0052] The present invention further discloses a preparation method of the above-mentioned conductive film, including:

[0053] s1: Mix and stir graphene, graphite powder and metal powder;

[0054] s2: Add adhesive and conductive powder, stir at room temperature, and then dry.

[0055] The present invention further provides a heat-generating mica board, comprising at least one piece of rubber-impregnated paper and the above-mentioned conductive film cured on the surface of the rubber-impregnated paper.

[0056] Further, the impregnated paper includes a mica paper base and an adhesive cured on the mica paper base, and the glue content of the impregnated paper is 9-10% after excluding the solvent.

[0057] Further, a heat-generating mica board includes multiple sheets of rubberized paper and the above-mentioned conductive film cured on the surface of the uppermost layer or the lowermost layer of rubberized paper.

[0058] refer to figure 2 As shown, the present invention pro...

Embodiment 1

[0088] The conductive powder includes: 10 parts of single-layer graphene, 75 parts of 1000 mesh graphite powder, 15 parts of 200 mesh heating iron powder;

[0089] The conductive film includes: 20 parts of conductive powder and 80 parts of adhesive; wherein, the adhesive is prepared by stirring 20 parts of 1153 silicone resin and 80 parts of industrial alcohol at room temperature.

Embodiment 2

[0091] The conductive powder includes: 15 parts of single-layer graphene, 70 parts of 1000-mesh graphite powder, 15 parts of 200-mesh heating aluminum powder;

[0092] The conductive film includes: 20 parts of conductive powder and 80 parts of adhesive; wherein, the adhesive is prepared by stirring 20 parts of 1153 silicone resin and 80 parts of industrial alcohol at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com