Lithium silicate coated lithium-rich manganese-based positive electrode material and preparation method and application thereof

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., to achieve the effect of solving instability, inhibiting the formation of intergranular cracks, and improving capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

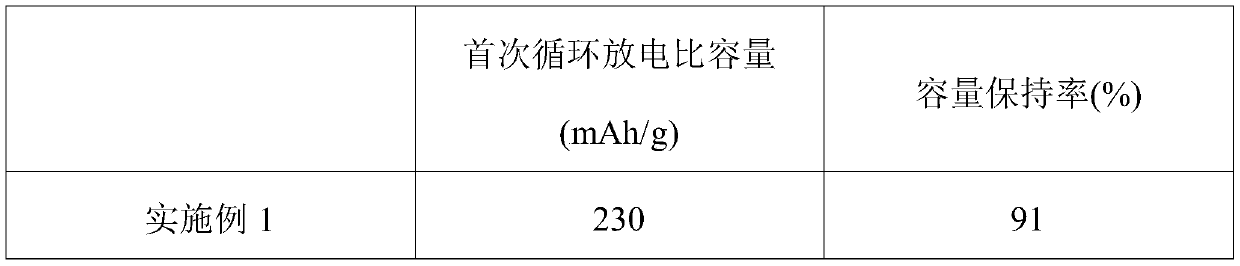

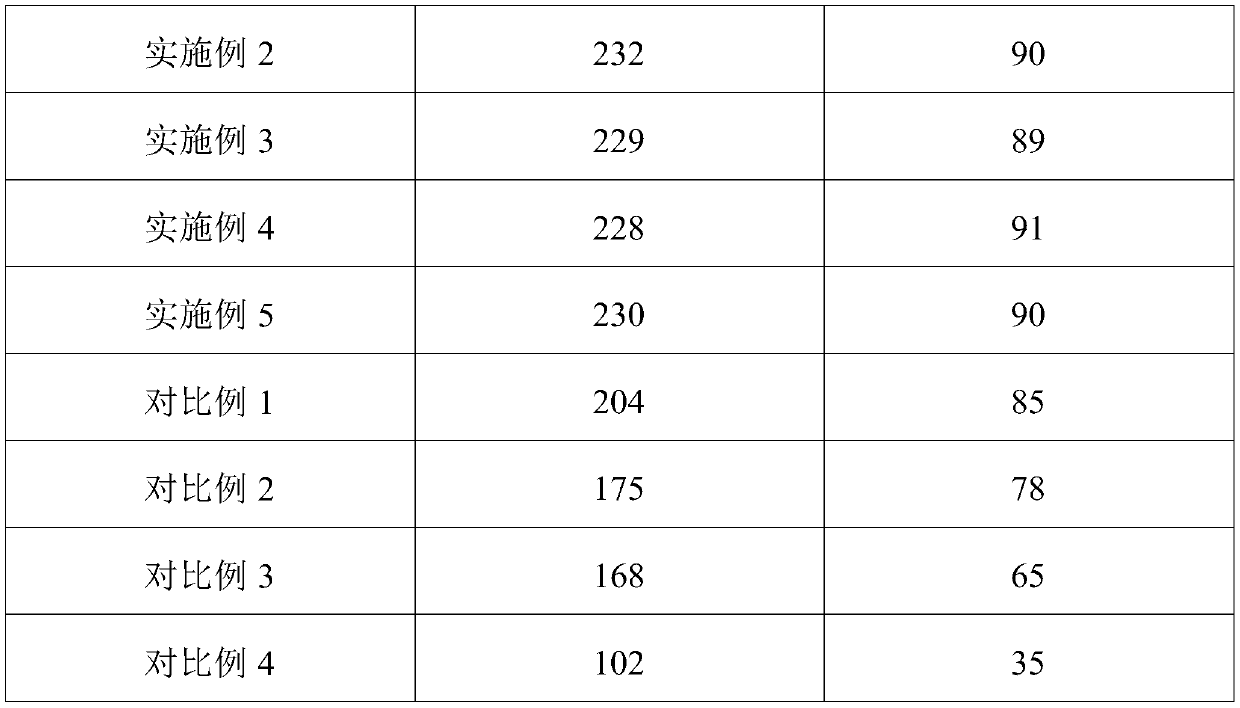

Examples

Embodiment 1

[0058] This embodiment provides a lithium-rich manganese-based positive electrode material coated with lithium silicate Li 2 mn 0.5 Ti 0.5 o 2 F / Li 2 SiO 3 The preparation method, described preparation method comprises the steps:

[0059] (1) mixing the mixed salt solution of manganese sulfate and titanium sulfate, the concentration of hydroxide ion is the sodium hydroxide solution of 5mol / L, the ammoniacal liquor of 8mol / L and the pH value of the bottom liquid to the mixed solution is 10; Liquid is (NH 4 ) 2 SO 4 Mixed aqueous solution with NaOH, in the bottom liquid (NH 4 ) 2 SO 4 The concentration of NaOH is 1.5mol / L, and the concentration of NaOH is 1.5mol / L; the solid-liquid separation is carried out after 12 hours of reaction at 50°C under stirring conditions, and the precursor Mn is obtained after the solid is washed and dried. 0.5 Ti 0.5 (OH) 2 , Mn in the mixed salt solution 2+ with Ti 4+ The total concentration is 10mol / L, the drying temperature is 70°...

Embodiment 2

[0064] This embodiment provides a lithium-rich manganese-based positive electrode material coated with lithium silicate Li 2 mn 0.5 Zr 0.5 o 2 F / Li 2 SiO 3 The preparation method, described preparation method comprises the steps:

[0065] (1) mixing the mixed salt solution of manganese acetate and zirconium sulfate, the concentration of hydroxide ion is the potassium hydroxide solution of 10mol / L, the ammoniacal liquor of 2mol / L and the pH value of the bottom liquid to the mixed solution is 13; Liquid is (NH 4 ) 2 SO 4 Mixed aqueous solution with NaOH, in the bottom solution (NH 4 ) 2 SO 4 The concentration of NaOH is 0.5mol / L, and the concentration of NaOH is 0.5mol / L; after 24 hours of reaction at 70°C under stirring conditions, solid-liquid separation is carried out. After the solid is washed and dried, the precursor Mn 0.5 Zr 0.5 (OH) 2 , Mn in the mixed salt solution 2+ with Zr 4+ The total concentration is 0.01mol / L, the drying temperature is 120°C, and th...

Embodiment 3

[0070] This embodiment provides a lithium-rich manganese-based positive electrode material coated with lithium silicate Li 2 mn 0.5 Ti 0.5 o 2 F / Li 2 SiO 3 The preparation method, described preparation method comprises the steps:

[0071] (1) mixing the mixed salt solution of manganese acetate and tetrabutyl titanate, the concentration of hydroxide ions being 6mol / L sodium hydroxide solution, 4mol / L ammonia water and the bottom liquid until the pH value of the mixed solution is 11; The bottom liquid is (NH 4 ) 2 SO 4 Mixed aqueous solution with NaOH, in the bottom solution (NH 4 ) 2 SO 4 The concentration of NaOH is 1 mol / L, and the concentration of NaOH is 1 mol / L; the solid-liquid separation is carried out after 5 hours of reaction at 60°C under stirring conditions, and the precursor Mn is obtained after the solid is washed and dried. 0.5 Ti 0.5 (OH) 2 , Mn in the mixed salt solution 2 + with Ti 4+ The total concentration is 2mol / L, the drying temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com