A processing technology for vacuum heat insulation panels with installation holes and not afraid of surface damage

A technology of vacuum heat insulation and processing technology, which is applied in the direction of heat exchange equipment, pipes protected by heat insulation, synthetic resin layered products, etc. It can solve the problems of bulging, low surface puncture resistance, poor toughness, etc. Good heat insulation effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

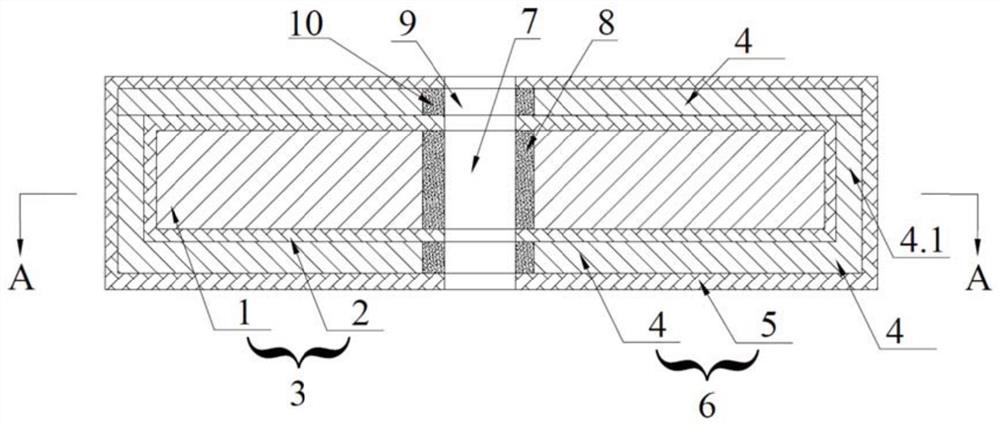

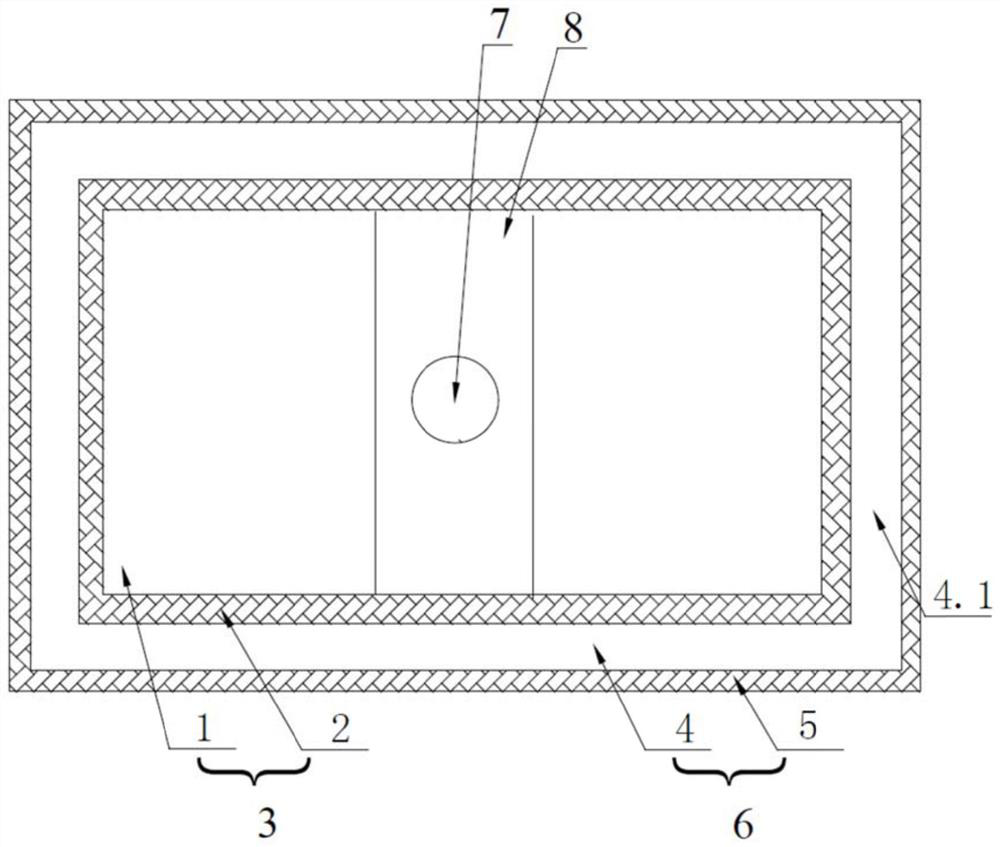

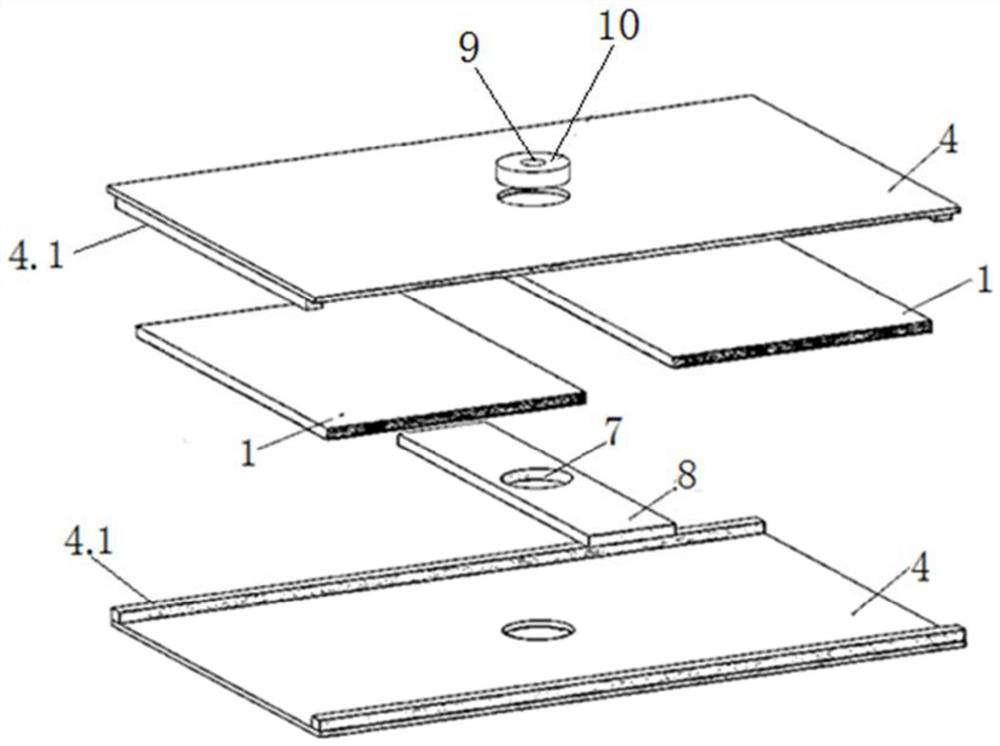

[0033] A processing technology for a vacuum insulation panel with installation holes and not afraid of surface damage, the processing technology includes the following process steps:

[0034] The first step is to manufacture the inner core board 1 by a dry method, and use glass fiber filaments, fumed silica, nano-microporous materials, aerogels, fumed silica, nano-microporous materials, and airgel The carding machine is combed into flakes and laid on the conveyor belt. The conveyor belt transfers the flakes to the cutting machine. The cutting machine cuts the flakes into the set specifications, and the cut flakes are put into the mold cavity layer by layer. There are multiple layers inside, and a filling layer is laid between the layers. The inner core board 1 forms the installation groove of the getter material and the installation groove of the inner partition 1 through the mold, or processes the getter material on the inner core board 1 for installation. Groove and inner pa...

Embodiment 2

[0043] On the basis of Example 1, the difference between this Example 5 and Example 4 lies in that: the wrapped outer core board 4, the medium-alkali or alkali-free glass fiber with a diameter of 4um is chopped, and the fiber diameter is 8μm Mineral wool, fumed silica, aerogel, solid viscose and mica powder, according to the content of medium-alkali glass fiber chopped strands is 25 parts by weight, the content of mineral wool is 50 parts by weight, and the content of fumed silica is 5 parts by weight, the content of airgel is 5 parts by weight, the content of solid viscose is 3 parts by weight, and the content of mica powder is 8 parts by weight. Make a slurry with water, and transport the evenly stirred slurry to the forming net. Flat, then remove moisture by rolling and drying, and then press into a flat core board by high-temperature hot molding, and then make a slurry with water from moisture-proof agent, perlite powder, and radiation barrier agent. The content of moisture...

Embodiment 3

[0047] On the basis of Example 1, the difference between this Example 4 and Example 4 lies in that: the wrapped outer core board 4, the medium-alkali or alkali-free glass fiber with a diameter of 9um is chopped, and the fiber diameter is 12μm Mineral wool, fumed silica, aerogel, solid viscose and mica powder, according to the content of medium-alkali glass fiber chopped strands is 25 parts by weight, the content of mineral wool is 50 parts by weight, and the content of fumed silica is 5 parts by weight, the content of airgel is 5 parts by weight, the content of solid viscose is 3 parts by weight, and the content of mica powder is 10 parts by weight. Make a slurry with water, and transport the evenly stirred slurry to the forming net. Flat, then remove moisture by rolling and drying, and then press into a flat core board by high-temperature hot molding, and then make a slurry from moisture-proof agent, perlite powder, and radiation barrier agent with water. The content of moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com