A passive heat conduction device and a secondary side passive cooling system

A passive, heat-collecting tank technology, used in cooling devices, nuclear power generation, greenhouse gas reduction, etc., can solve the problems of difficult-to-exchange hot water tank connection, equipment corrosion, affecting sealing effect, etc., to improve stability and reliability. The effect of prolonging the service life and reducing the negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

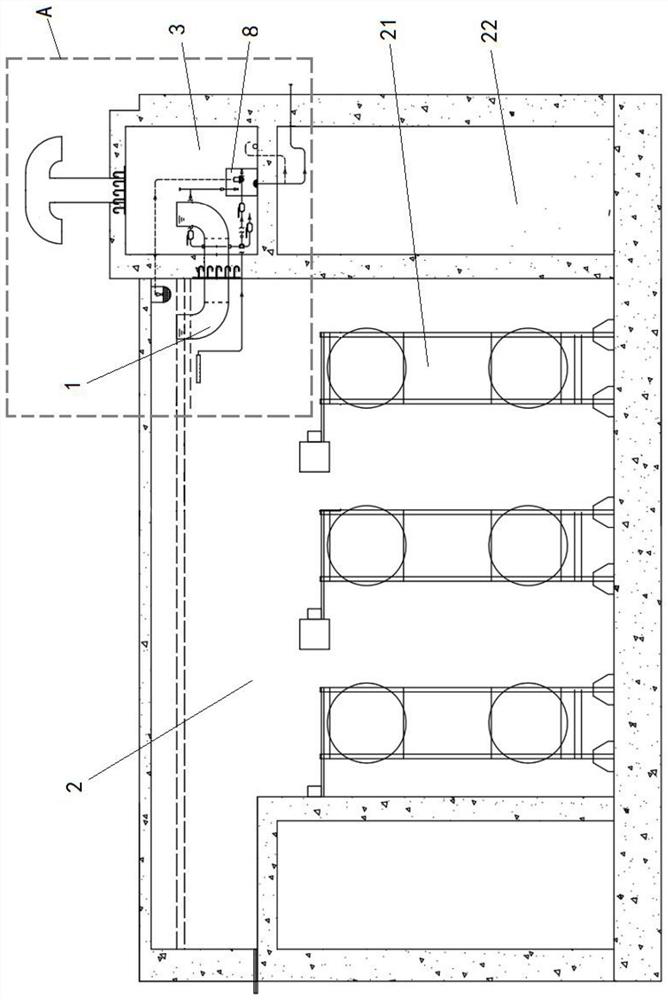

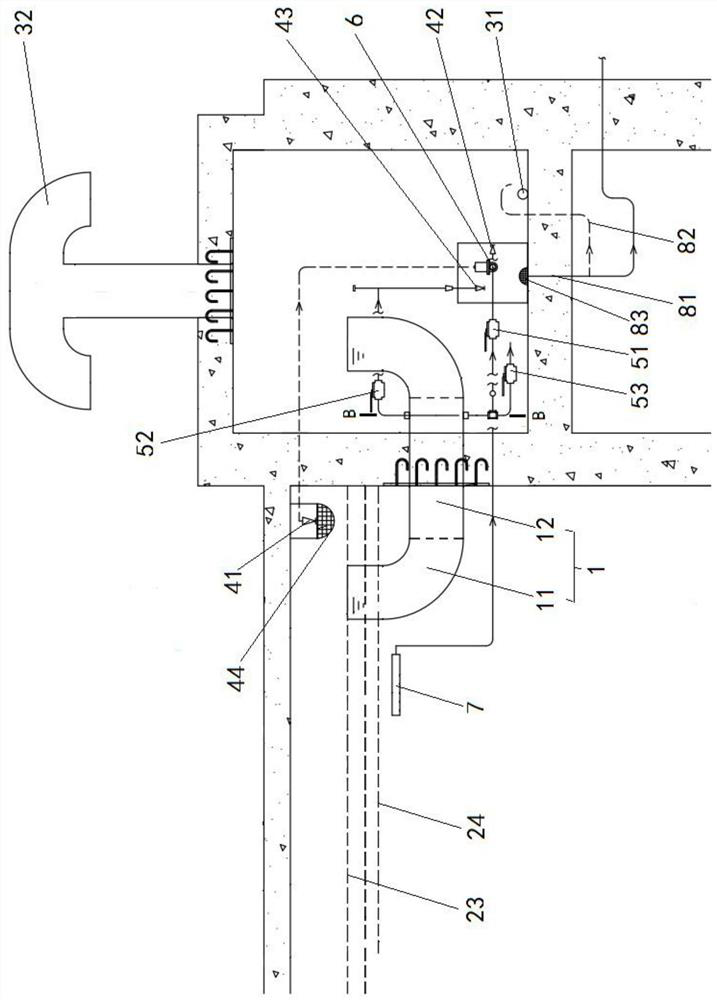

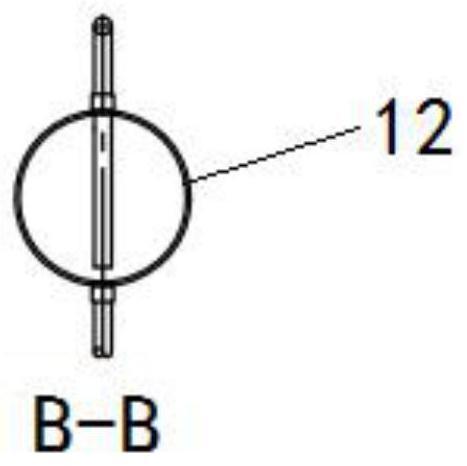

[0062] Such as Figure 1-Figure 5 As shown, this embodiment discloses a passive heat conduction device, including a U-shaped tube 1 and an auxiliary unit, wherein:

[0063] U-shaped pipe 1, one end of which extends into the heat exchange tank 2, and the other end communicates with the outside, and a sealing medium is placed inside the U-shaped pipe 1 for isolating the heat exchange tank 2 from the external environment;

[0064] Auxiliary unit, including heat collection tank 8, steam pipeline, emptying pipeline, and first control part and second control part, wherein, the two ends of steam pipeline communicate with heat exchange tank 2, heat collection tank 8 respectively, The steam pipeline is closed under normal working conditions (i.e. under normal conditions), and the first control component is used to control the opening of the steam pipeline under accident conditions; one end of the emptying pipeline communicates with the inside of the U-shaped pipe 1, and the other One ...

Embodiment 2

[0118] Such as Figure 1-Figure 6 As shown, this embodiment discloses a passive cooling system on the secondary side, that is, the PRS system, which includes a heat exchange tank 2, a heat conduction tank 3, and the passive heat conduction device (referred to as the heat conduction device) in Embodiment 1. One end of the U-shaped pipe in the heat conduction device extends into the heat exchange tank 2 , and the other end extends into the heat conduction tank 3 .

[0119] Specifically, the heat exchange tank 2 is a closed concrete structure for storing cooling water. The inner wall of the heat exchange tank 2 is provided with a steel cladding surface to improve sealing and corrosion resistance. The central area of the top of the heat exchange tank 2 is provided with a prefabricated concrete cover structure 25 , and the cover structure 25 is sealed and connected with the top of the heat exchange tank 2 . In this embodiment, the size of the cover structure 25 is preferably 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com