Method and system for determining convective heat dissipation coefficient

A technology of heat dissipation coefficient and determination method, which is applied in the field of determination method and system of convection heat dissipation coefficient, and can solve problems such as insufficient convection heat dissipation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

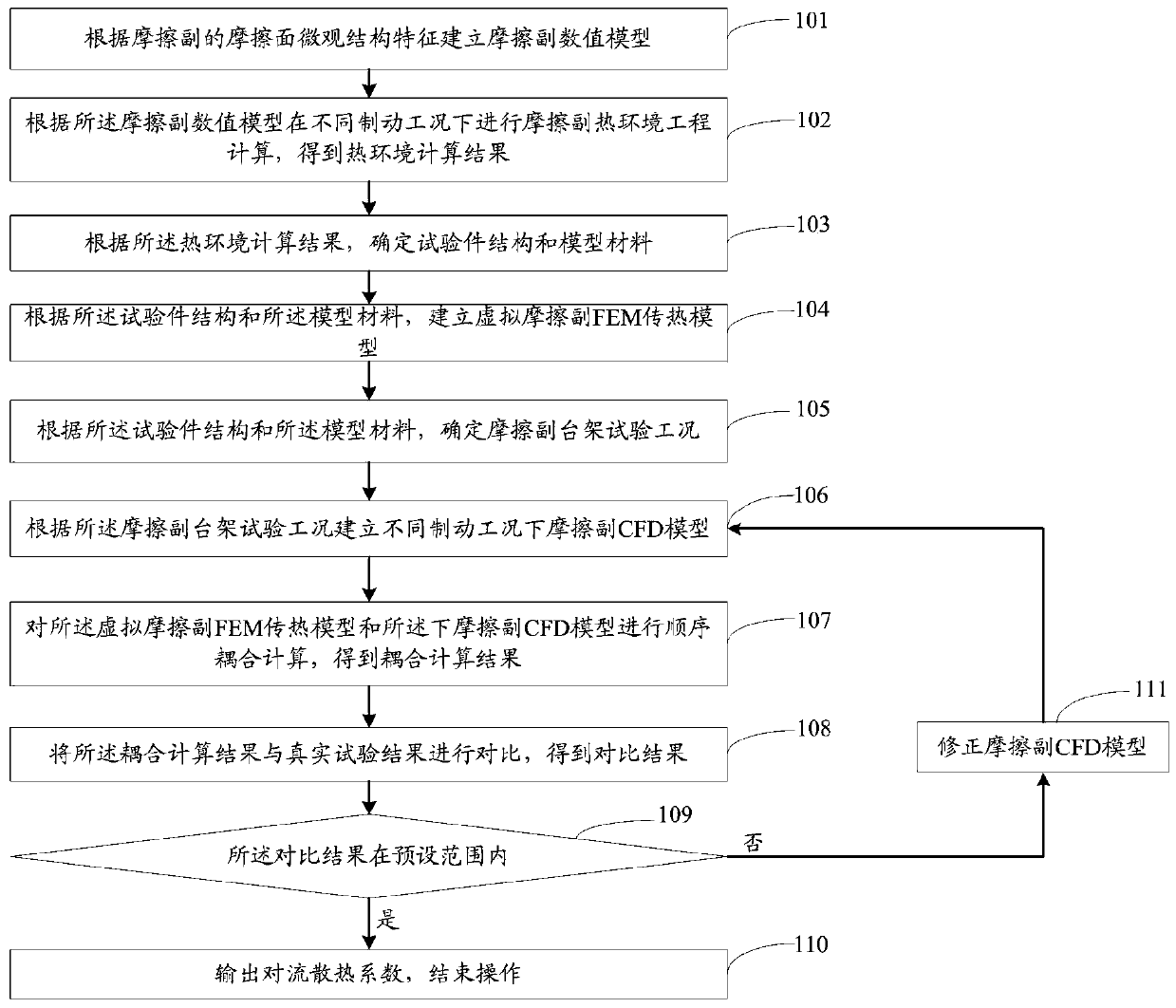

[0172] In addition to providing Embodiment 1, the present invention also provides Embodiment 2 corresponding to the technical solution of Embodiment 1. Figure 14 It is a system structure diagram for determining the convection heat dissipation coefficient of the present invention. like Figure 14 As shown, a convective heat dissipation coefficient determination system includes:

[0173] The friction pair numerical model establishment model 201 is used to establish a friction pair numerical model according to the microstructure characteristics of the friction surface of the friction pair.

[0174] The thermal environment calculation result determination module 202 is used to perform thermal environment engineering calculation of the friction pair under different braking conditions according to the friction pair numerical model, and obtain the thermal environment calculation result.

[0175] The test piece structure and model material determination module 203 is used to determ...

Embodiment 3

[0213] A heat-fluid-solid coupling calculation of SiC 3D The method of the friction pair of / Al composite material specifically comprises:

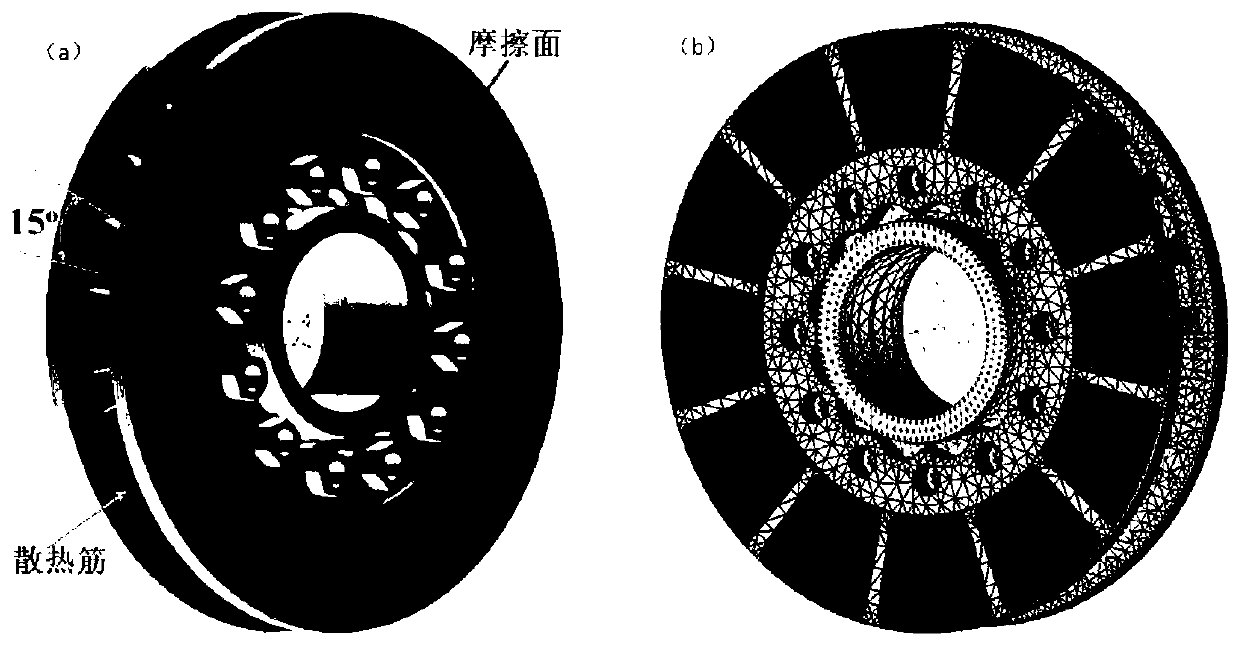

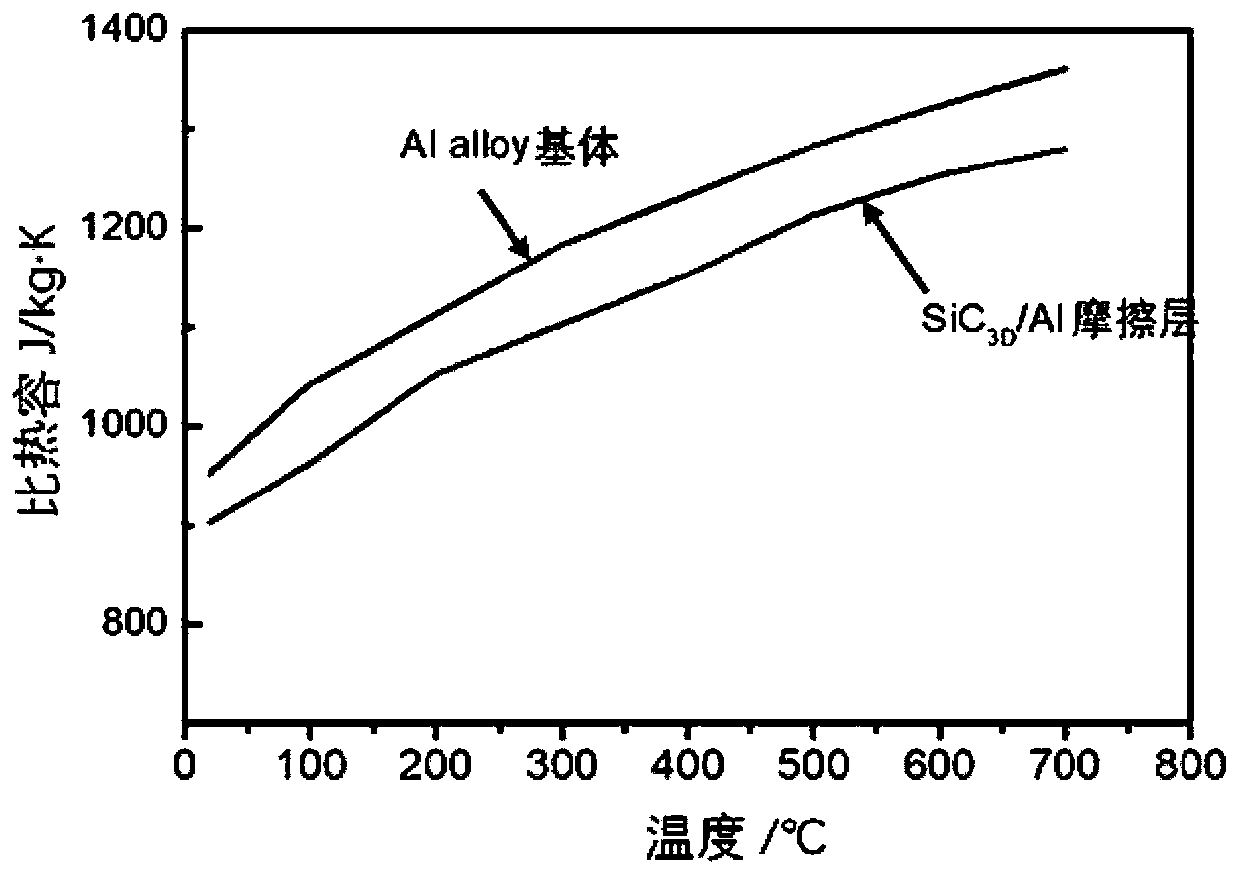

[0214] The finite element model of the friction pair is established with Solidworks. The disc body has 24 slat-shaped heat dissipation ribs and ventilation slots, which are symmetrically distributed on the back of the brake disc. The heat dissipation ribs are designed to be flat near the central axis to reduce the pump wind resistance torque and reduce resistance power consumption. The position of the bolt holes is simplified without affecting the calculation accuracy. The brake disc is assembled with the axle, which runs through the entire computational domain, see Figure 8 . The friction layer of the brake disc is SiC with a thickness of 5-7mm 3D / Al composite material, aluminum-silicon alloy for the rest of the disc body, physical parameters of the material. The specific heat capacity of the material changes greatly with the incr...

Embodiment 4

[0234] The invention provides a heat-fluid-solid coupling computing belt (Al 2 o 3 ) 3D The method for the automobile friction pair of / Al friction layer, comprises the steps:

[0235] Establish the numerical model of friction pair of Audi A6. The numerical model of friction pair is divided by using tetrahedral mesh and mixed mesh of hexahedron and tetrahedron. The main parameters of each component in the finite element model are the density of spokes, rims and bolt components is 7840kg / m 3 , specific heat at constant pressure is 465J / (kg K), thermal conductivity is 48W / (m K); the friction layer of the brake disc is (Al 2 o 3 ) 3D / Al composite material, the thickness of the friction layer is 3mm; the air density is 1.029kg / m 3 , the coefficient of dynamic viscosity is 2.06×10 -5 kg / (m·s), specific heat at constant pressure is 1009J / (kg·K), and thermal conductivity is 0.0296W / (m·K). The material of the friction surface composite material is calculated according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com