Radiative cooling film and production method and application thereof

A radiative cooling and film technology, applied in the field of radiative cooling film and its preparation, can solve the problems of reducing solar radiation reflectivity, earth environment and biological damage, greenhouse effect and air pollution, etc., to achieve improved safety performance, excellent transparency, The effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

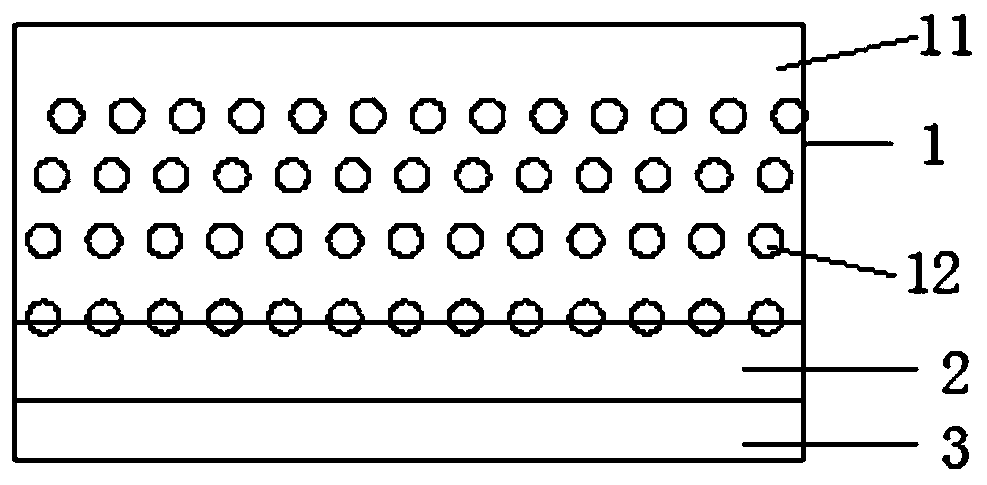

[0053] refer to figure 1 , a radiation cooling film, which is composed of a radiation cooling layer 1, a smooth layer 2 and a reflection layer 3 in sequence, and the thicknesses are 45 microns, 5 microns, and 0.04 microns in sequence.

[0054] Wherein, the radiation cooling layer 1 comprises a polylactic acid resin matrix 11 and particles 12 dispersed in the polylactic acid resin matrix 11, the polylactic acid resin matrix 11 comprises polylactic acid, a coupling agent and a light stabilizer, and the amount of each substance in the radiation cooling layer 1 is It is: 94 parts by weight of polylactic acid, 6 parts by weight of microparticles 12, 0.03 parts of coupling agent, and 0.15 parts of light stabilizer. The coupling agent is silane coupling agent KH560, and the light stabilizer is UV326.

[0055] Particles 12 are silicon dioxide and have a size of 4±2 microns. The surface of the radiative cooling layer 1 near the smooth layer 2 is uneven due to the dispersed presence o...

Embodiment 2

[0057] A radiation cooling film is composed of a radiation cooling layer 1, a smooth layer 2 and a reflection layer 3 in sequence, and the thicknesses are 65 microns, 14 microns and 0.15 microns in sequence.

[0058] Wherein, the radiation cooling layer 1 comprises a polylactic acid resin matrix 11 and particles 12 dispersed in the polylactic acid resin matrix 11, the polylactic acid resin matrix 11 comprises polylactic acid, a coupling agent and a light stabilizer, and the amount of each substance in the radiation cooling layer 1 is It is: 82 parts by weight of polylactic acid, 18 parts by weight of microparticles 12, 0.18 parts of coupling agent, and 0.1 part of light stabilizer. The coupling agent is silane coupling agent KH550, and the light stabilizer is UV326 and UV5050.

[0059] The particle 12 is a mixture of silicon dioxide and silicon carbide, the size of which is 15±2 microns, and the mass ratio of the two is 3:2. The surface of the radiative cooling layer 1 near t...

Embodiment 3

[0061] A radiation cooling film is composed of a radiation cooling layer 1, a smooth layer 2 and a reflection layer 3 in sequence, and the thicknesses are 50 microns, 10 microns and 0.1 microns in sequence.

[0062] Wherein, the radiation cooling layer 1 comprises a polylactic acid resin matrix 11 and particles 12 dispersed in the polylactic acid resin matrix 11, the polylactic acid resin matrix 11 comprises polylactic acid, a coupling agent and a light stabilizer, and the amount of each substance in the radiation cooling layer 1 is It is: 90 parts by weight of polylactic acid, 10 parts by weight of microparticles 12, 0.05 parts of coupling agent, and 1 part of light stabilizer. The coupling agent is silane coupling agent KH550, and the light stabilizer is UV326 and UV329 mixed in a mass ratio of 1:1.

[0063] The particle 12 is a mixture of silicon dioxide and aluminum oxide, the size of which is 10±2 microns, and the mass ratio of the two is 4:1. The surface of the radiativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com