Method for preparing functional polyvinylidene fluoride membrane

A polyvinylidene fluoride membrane and polyvinylidene fluoride technology, applied in the field of separation membranes, can solve the problems of being easily affected by organic matter and microorganisms, low surface energy of PVDF, strong hydrophobicity, etc., and achieve good biocompatibility and degradability properties, good antibacterial properties and hydrophilic properties, and facilitate grafting reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

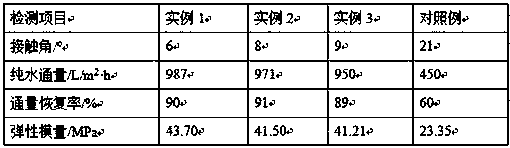

example 1

[0037] Take modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N-dimethylacetamide, and mix modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N- Mix dimethylacetamide, stir at 80°C for 3 hours, let stand for defoaming for 1 hour to obtain casting solution, pour the casting solution on a clean and horizontal glass plate and place it in an oven at 40°C Dry to constant weight, cool to room temperature, and peel off the film to obtain a functional polyvinylidene fluoride film. The preparation steps of modified polyvinylidene fluoride powder are as follows: mix starch and deionized water according to the mass ratio of 1:20, stir and gelatinize to obtain gelatinized starch liquid; add polyvinylidene fluoride powder to the gelatinized starch liquid, Stirring was continued for 1 h under a nitrogen atmosphere at a temperature of 60° C., and cooled to room temperature to obtain modified polyvinylidene f...

example 2

[0039] Take modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N-dimethylacetamide, and mix modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N- Mix dimethylacetamide, stir at 85°C for 3 hours, let it stand for 1 hour to defoam, and get the casting solution. Pour the casting solution on a clean and horizontal glass plate and put it in an oven at 50°C. Dry to constant weight, cool to room temperature, and peel off the film to obtain a functional polyvinylidene fluoride film. The preparation steps of modified polyvinylidene fluoride powder are as follows: mix starch and deionized water according to the mass ratio of 1:20, stir and gelatinize to obtain gelatinized starch liquid; add polyvinylidene fluoride powder to the gelatinized starch liquid, Stirring was continued for 1 h under a nitrogen atmosphere at a temperature of 65° C., and cooled to room temperature to obtain modified polyvinylidene ...

example 3

[0041] Take modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N-dimethylacetamide, and mix modified polyvinylidene fluoride powder, modified cellulose acetate, polyvinylpyrrolidone, N,N- Mix dimethylacetamide, stir at 90°C for 4 hours, let stand for defoaming for 2 hours to obtain casting solution, pour the casting solution on a clean and horizontal glass plate and place it in an oven at 60°C Dry to constant weight, cool to room temperature, and peel off the film to obtain a functional polyvinylidene fluoride film. The preparation steps of modified polyvinylidene fluoride powder are as follows: mix starch and deionized water according to the mass ratio of 1:20, stir and gelatinize to obtain gelatinized starch liquid; add polyvinylidene fluoride powder to the gelatinized starch liquid, Stirring was continued for 2 hours under a nitrogen atmosphere at a temperature of 70°C, and cooled to room temperature to obtain modified polyvinyliden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com