Biomass charcoal briquette fuel and preparation method thereof

A technology for forming fuel and biomass charcoal, which is applied in the fields of biofuel, waste fuel, fuel, etc., can solve the problems of high cost, high construction cost, high production cost and energy consumption, and achieve good adhesiveness, thermal stability improvement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

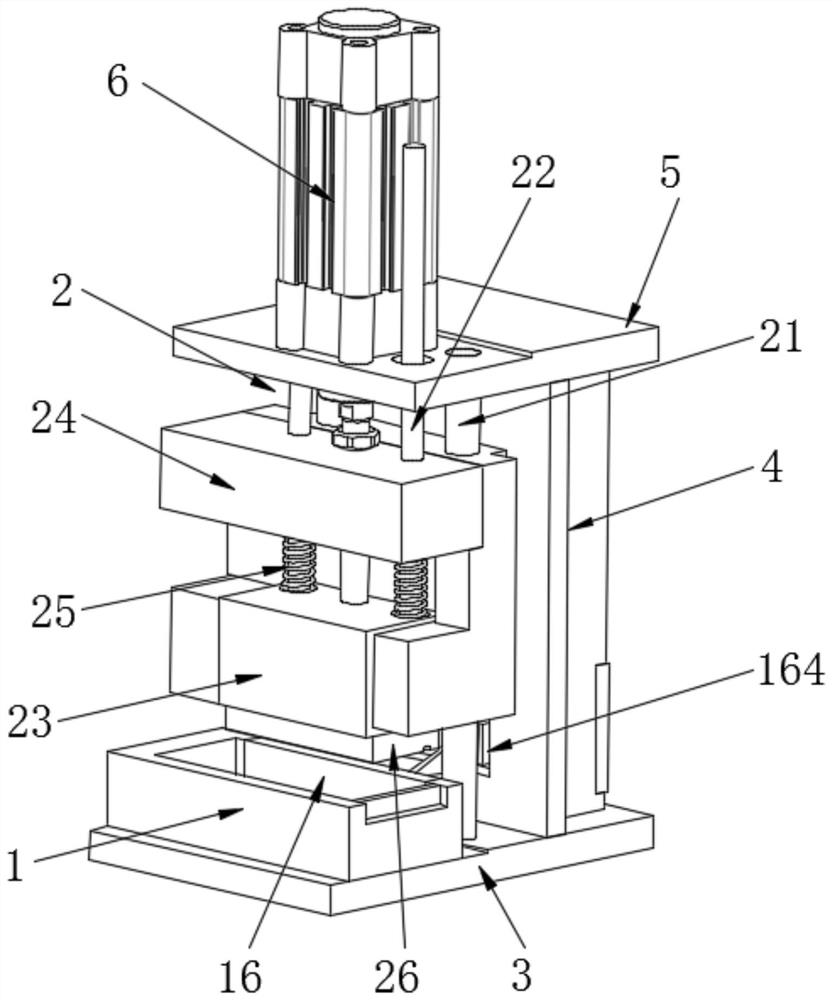

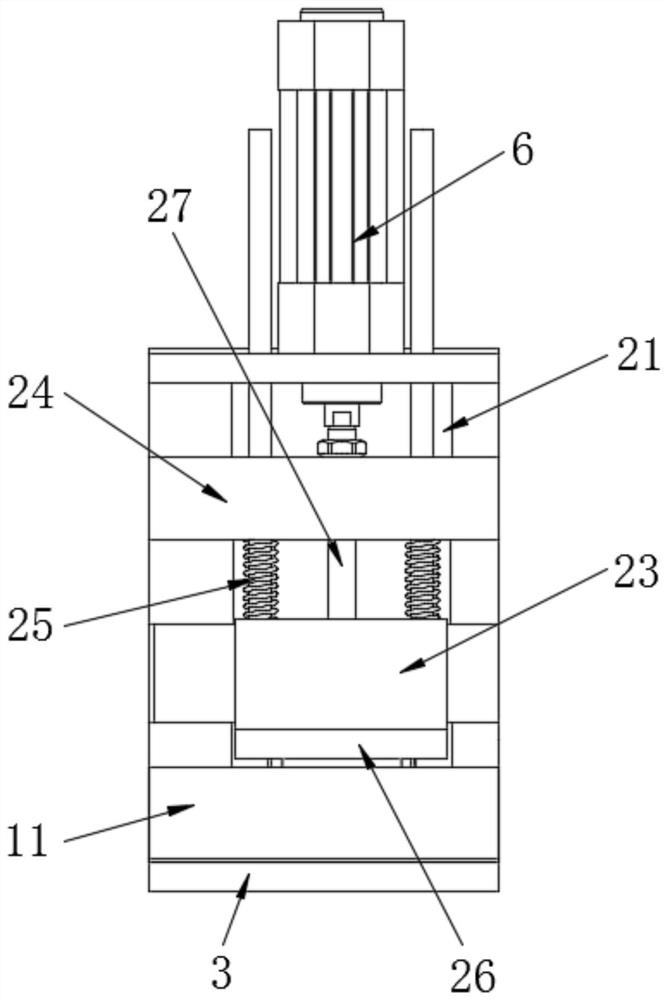

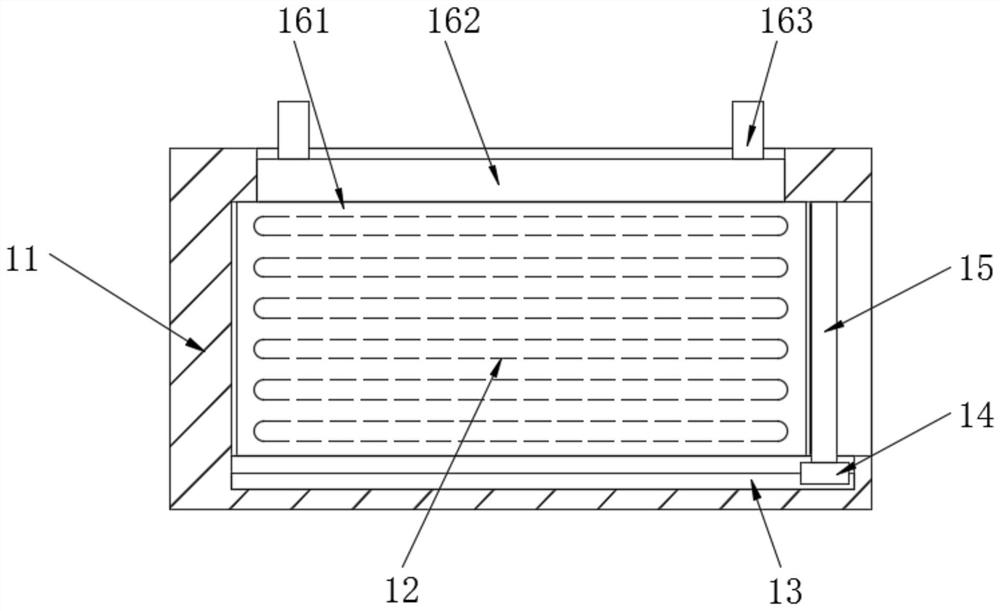

[0035] see Figure 1-3 Shown, a kind of biochar shaped fuel comprises carbon powder and binding agent, and the mixing mass ratio of carbon powder and binding agent is 15:100;

[0036] The biochar briquette fuel is prepared by the following method:

[0037] Step 1. Put the reed rods of biomass material into the muffle furnace, control the temperature rise rate of the muffle furnace to 10°C / min, until the temperature inside the muffle furnace reaches 300°C, and keep the constant temperature for 2 hours to obtain reed charcoal. The reed charcoal in the muffle furnace is taken out and cooled to 90°C, and the cooled reed charcoal is crushed with a plant grinder, the crushed reed charcoal is sieved, and the charcoal powder with a particle size of 0.2mm is selected and put into a sealed bag for later use ;

[0038] Step 2, using konjac powder as raw material to prepare binder, mix the prepared binder and charcoal powder evenly according to the mass ratio of 15:100, put the mixture ...

Embodiment 2

[0045] see Figure 1-3 Shown, a kind of biochar briquette fuel comprises charcoal powder and binding agent, and the mixing mass ratio of carbon powder and binding agent is 15:100;

[0046] The biochar briquette fuel is prepared by the following method:

[0047] Step 1. Put the reed rods of biomass material into the muffle furnace, control the temperature rise rate of the muffle furnace to 10°C / min, until the temperature inside the muffle furnace reaches 320°C, and keep the constant temperature for 2 hours to obtain reed charcoal. The reed charcoal in the muffle furnace is taken out and cooled to 105°C, and the cooled reed charcoal is crushed with a plant pulverizer, the crushed reed charcoal is sieved, and the charcoal powder with a particle size of 0.3mm is selected and put into a sealed bag for later use ;

[0048] Step 2, using konjac powder as raw material to prepare binder, mix the prepared binder and charcoal powder evenly according to the mass ratio of 15:100, put the...

Embodiment 3

[0055] see Figure 1-3 Shown, a kind of biochar briquette fuel comprises charcoal powder and binding agent, and the mixing mass ratio of carbon powder and binding agent is 15:100;

[0056] The biochar briquette fuel is prepared by the following method:

[0057]Step 1. Put the reed rods of biomass material into the muffle furnace, control the temperature rise rate of the muffle furnace to 10°C / min, until the temperature inside the muffle furnace reaches 310°C, and keep the constant temperature for 2 hours to obtain reed charcoal. The reed charcoal in the muffle furnace is taken out and cooled to 100°C, and the cooled reed charcoal is crushed with a plant grinder, and the crushed reed charcoal is sieved, and the charcoal powder with a particle size of 0.25 mm is selected and put into a sealed bag for later use ;

[0058] Step 2, using konjac powder as raw material to prepare binder, mix the prepared binder and charcoal powder evenly according to the mass ratio of 15:100, put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com