Coalescence material for emulsified water as well as preparation method and application of coalescence material

A technology of coalescing materials and emulsifying water, which is applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve the impact of the oil-water separation without considering the surfactant type and concentration, and the stability of the oil-water emulsion , Analyzing the impact of surfactants and other issues, to achieve the effect of improving the efficiency of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

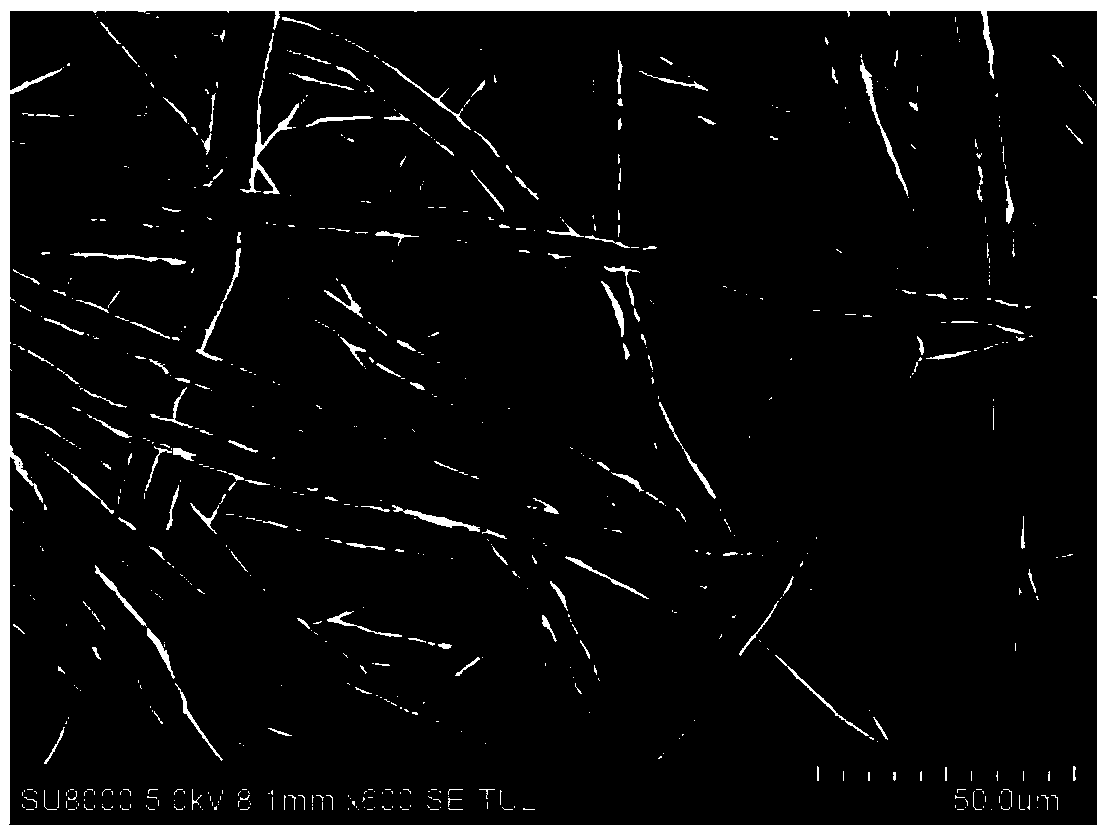

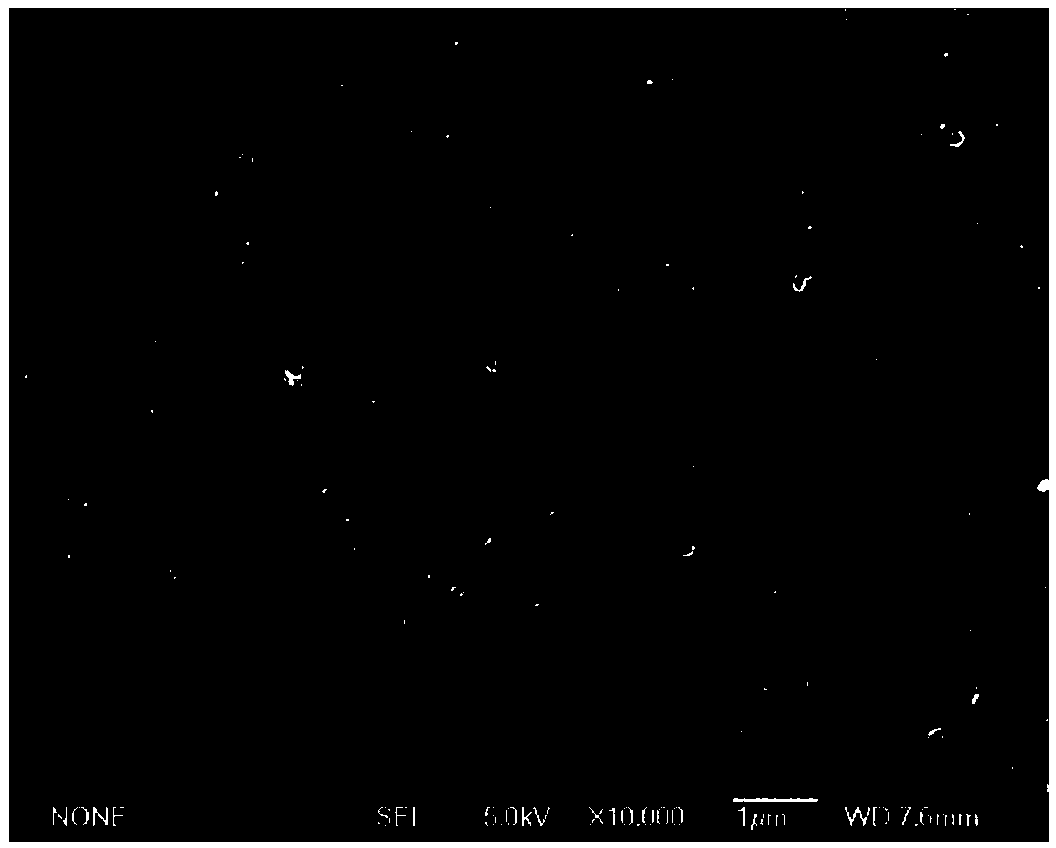

[0074] An emulsified water coalescing material, including stainless steel felt with a pore size of 8 μm and a fluorine-containing polyurethane coating coated on the surface of the stainless steel felt, the fluorine-containing polyurethane coating-C 3 f 7 -and-CH 2 CH 2 The molar ratio of O- is 6:1.

[0075] The preparation steps are as follows:

[0076](1) Preparation of fluorine-containing polyurethane emulsion: In a nitrogen atmosphere, under the condition of a constant temperature of 60°C, in parts by weight, add 6 parts of fluorine-containing alcohol (fluorine-containing alcohol structure: X-Y-N(R)-R' OH, wherein the number of carbon atoms in the fluorine-containing alkyl chain X is 3, the transition group Y is sulfoxyl, R and R' are alkyl chains with 3 and 5 carbon atoms respectively), acetone and dibutyltin diacetate , after fully mixing, add 5 parts of HDI, stir at constant temperature at 60°C for 2 hours, make it fully react to obtain the product; continue stirring...

Embodiment 2

[0081] An emulsified water coalescing material comprises a melt-blown polymer fiber filter medium with a pore size of 10 μm and a fluorine-containing polyurethane coating coated on the surface of the melt-blown polymer fiber filter medium. Fluorine-containing polyurethane coating-C 4 f 9 -and-CH 2 CH 2 The molar ratio of O- is 4:1.

[0082] The preparation steps are as follows:

[0083] (1) Preparation of fluorine-containing polyurethane emulsion: under a nitrogen atmosphere, at a constant temperature of 70°C, in parts by weight, add 4 parts of fluorine-containing alcohol (fluorine-containing alcohol structure: X-Y-N(R)-R'OH, Wherein the number of carbon atoms of the fluorine-containing alkyl chain X is 4, the transition group Y is a sulfoxyl group, R and R' are respectively an alkyl chain with 3 and 5 carbon atoms), acetone and dibutyltin diacetate, fully After mixing, add 2 parts of TDI, stir at a constant temperature of 70°C for 1 hour, make it fully react to obtain th...

Embodiment 3

[0088] An emulsified water coalescing material, comprising a stainless steel felt with a pore size of 12 μm and a fluorine-containing polyurethane coating coated on the surface of the stainless steel felt. Fluorine-containing polyurethane coating-C 5 f 11 -and-CH 2 CH 2 The molar ratio of O- is 4:1.

[0089] The preparation steps are as follows:

[0090] (1) Preparation of fluorine-containing polyurethane emulsion: under nitrogen atmosphere, at a constant temperature of 55°C, in parts by weight, add 2 parts of fluorine-containing alcohol (fluorine-containing alcohol structure: X-Y-N(R)-R'OH, The number of carbon atoms in the fluorine-containing alkyl chain X is 5, the transition group Y is sulfoxyl, R and R' are alkyl chains with 3 and 5 carbon atoms respectively), butanone and dibutyltin dilaurate After fully mixing, add 5 parts of TDI, stir at a constant temperature of 55 ° C for 2 hours, make it fully react to obtain the product; continue to stir the above product at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com