Preparation method of environment-friendly fluorine-containing waterborne polyurethane

A water-based polyurethane, environmentally friendly technology, applied in the field of water-based polyurethane, to avoid serious environmental pollution, enhance water and oil repellency, and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

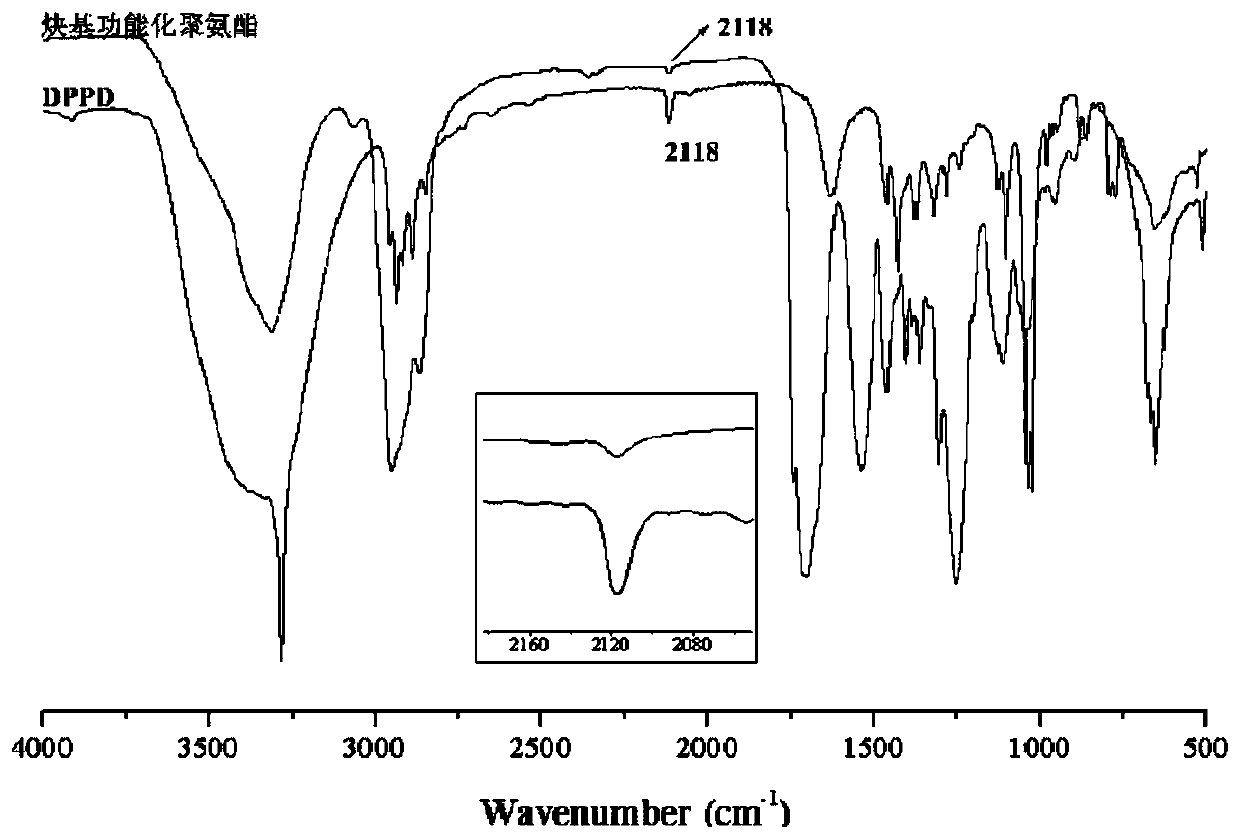

[0035] A method for preparing an environment-friendly fluorine-containing water-based polyurethane, comprising the steps of: introducing two fluorine-containing side chains on each alkynyl group of an alkynyl-functionalized polyurethane through a mercapto-alkyne click chemical reaction to obtain a fluorine-containing side chain polyurethane; The fluorine-containing side chain polyurethane is emulsified to obtain an environment-friendly fluorine-containing water-based polyurethane; the number of carbon atoms in the fluorine-containing side chain of the fluorine-containing side chain polyurethane is less than 8.

[0036] One of the objectives of the present invention is to provide an environmentally friendly side chain fluorinated water-based polyurethane with water resistance and oil resistance, which can replace long fluorine segment polyurethane to play an environmental protection role, and by improving the migration ability and density of fluorine segment To endow polyurethan...

Embodiment 1

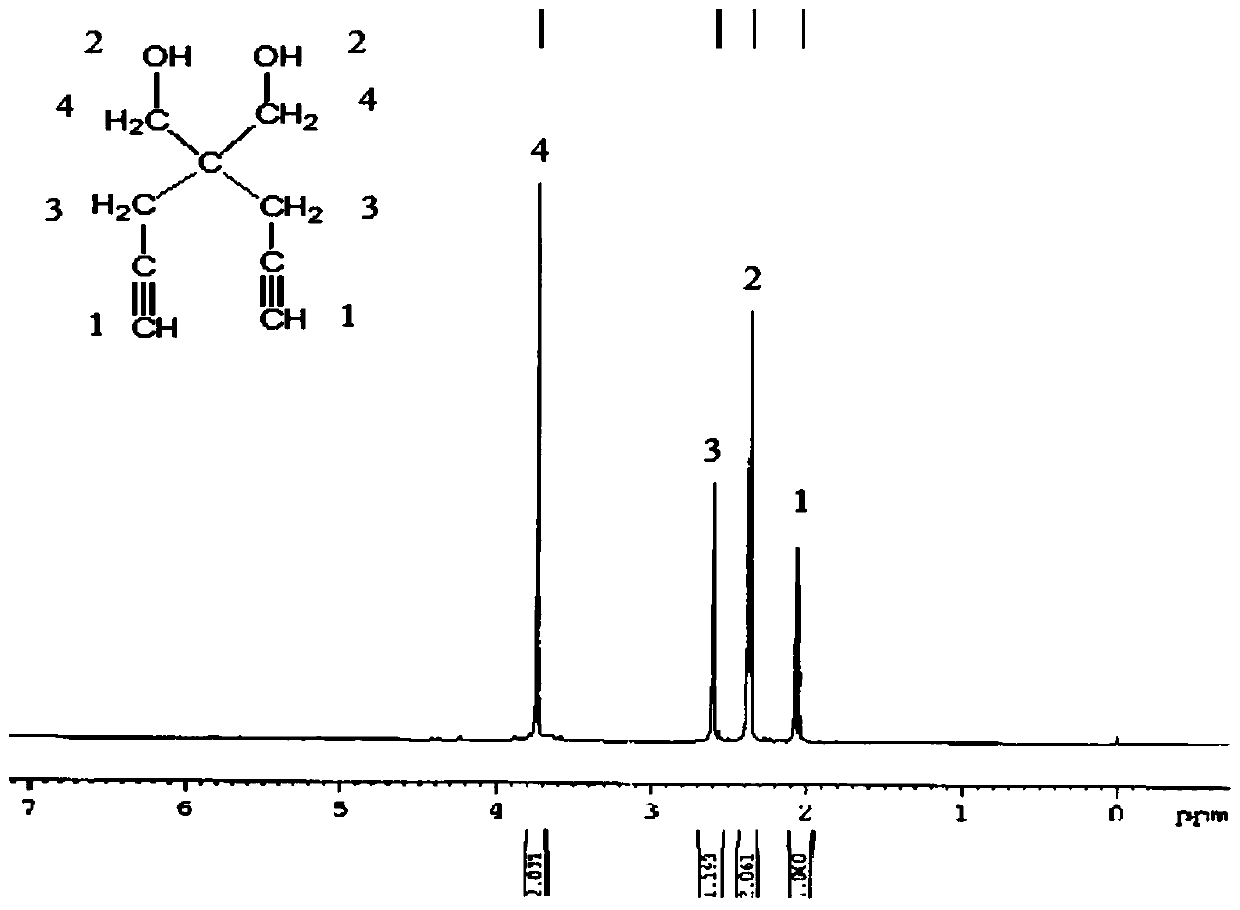

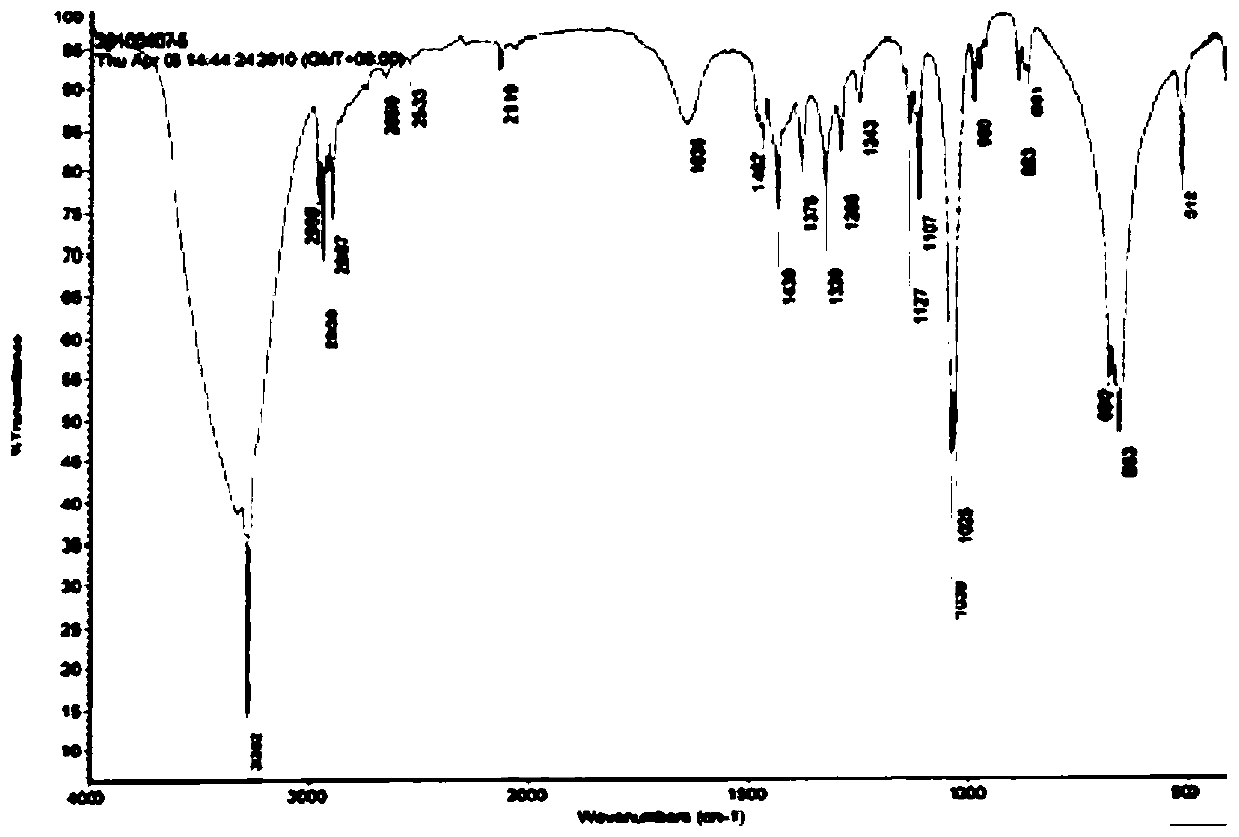

[0069] Firstly, 4,4′-dimethylol-1,4-heptadiyne (DPPD) was synthesized as a diol monomer for introducing alkynyl groups. First, add 150ml of absolute ethanol into a dry flask, and after blowing nitrogen gas, add 6.5g of freshly cut sodium filaments into the flask several times, and then add 20g of diethyl malonate after no hydrogen steam drum is generated. After uniform magnetic stirring, the temperature of the reaction system was raised to 60° C., and then 32.6 g of propargyl bromide was slowly added dropwise into the flask. After the dropwise addition, the system was kept under reflux for 12h. After removal of the solvent, precipitation in diethyl ether afforded a solid diethyl propargyl malonate intermediate. Next, 150ml of anhydrous THF was added into the flask, and the flask was placed in an ice bath under nitrogen protection. Then under magnetic stirring, 4.6g LiAlH 4 Slowly add it into the flask, stir evenly, dissolve 7.5g diethyl propargyl malonate in 50ml THF and dr...

Embodiment 2

[0074] This example is basically the same as Example 1, except that 0.9g of dimethylol propionic acid is replaced by 0.7g of diethylenetriamine. After mercapto-alkyne click chemistry, 0.8 g of triethylamine was replaced with 0.48 g of glacial acetic acid. After testing, the surface contact angle of the treated fabric is 120±5°, Figure 5 , The water absorption rate of the treated fabric is about 14%. According to the national standard GB-T 4745-1977, the water repellency level of the wet sample is rated as 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com