Preparation method of mesoporous TiO2 whisker, distillate oil hydrodesulfurization catalyst and preparation method of distillate oil hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, which is applied in chemical instruments and methods, crystal growth, and hydrocarbon oil treatment, can solve the problems of high cost of whisker preparation and low desulfurization rate of hydrodesulfurization catalyst, and achieve simple preparation conditions and processes Easy to control, conducive to industrial scale preparation, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

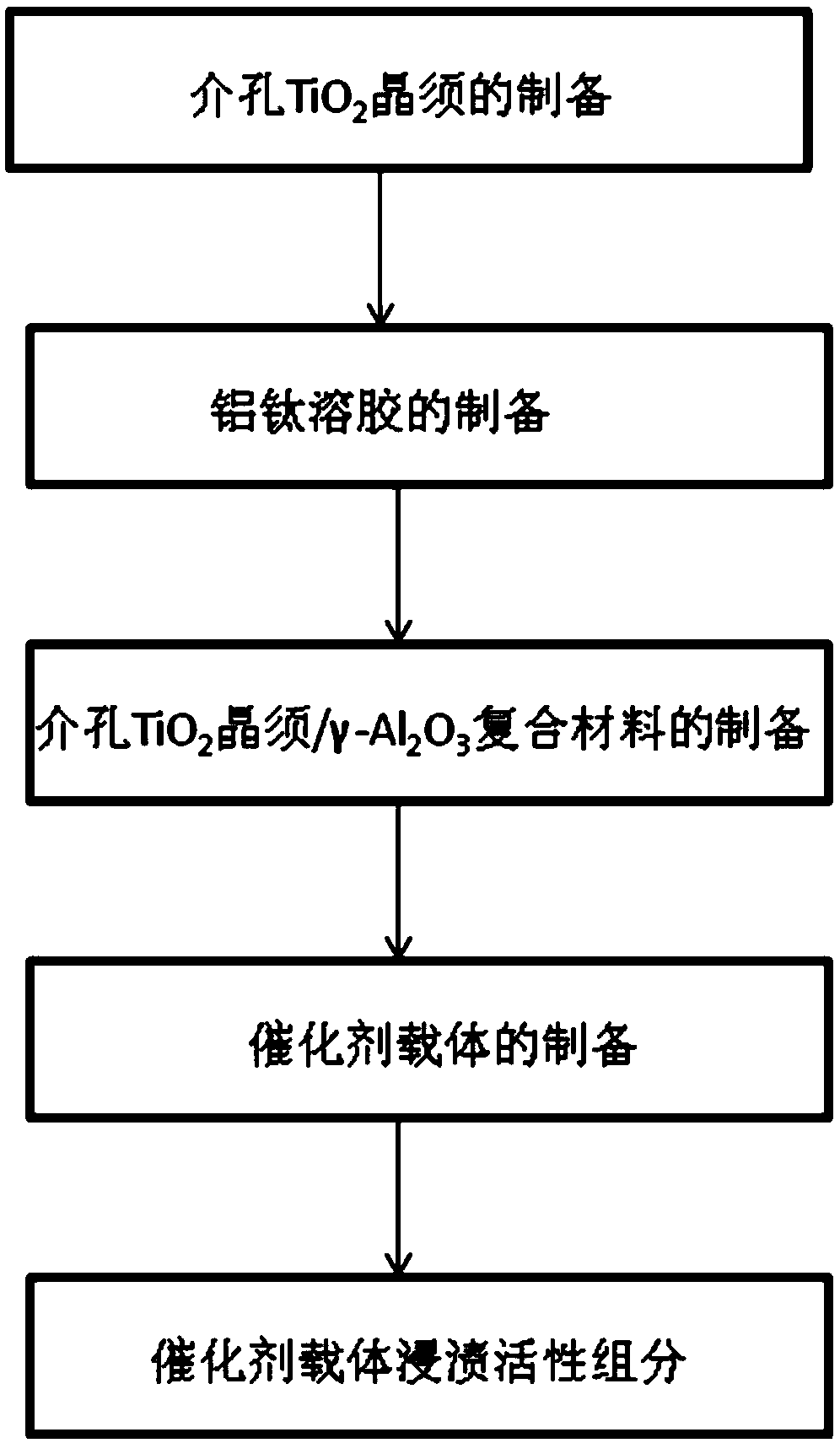

Method used

Image

Examples

preparation example Construction

[0035] The invention discloses a mesoporous TiO 2 The preparation method of whisker, this method comprises the steps:

[0036] Step 1, add water dropwise to potassium titanate, stir, then seal and let stand for 3 to 15 days;

[0037] Step 2, disperse the substance after standing in step 1 into water, the mass ratio of the substance after standing in step 1 to water is 1:100~1:500, then add hydrochloric acid dropwise, adjust the pH value to 1~10, stir 18~48h for the first ion exchange reaction;

[0038] Step 3, sedimentation and suction filtration of the emulsion after the first ion exchange reaction, washing and drying the precipitate to obtain dititanic acid; and

[0039] Step 4, immerse the dititanic acid obtained in step 3 into KOH aqueous solution to carry out the second ion exchange reaction, the concentration of KOH aqueous solution is 5-30wt%, after standing for 2-24h, filter and dry to obtain mesoporous TiO 2 whiskers.

[0040] Specifically, the technical solution is...

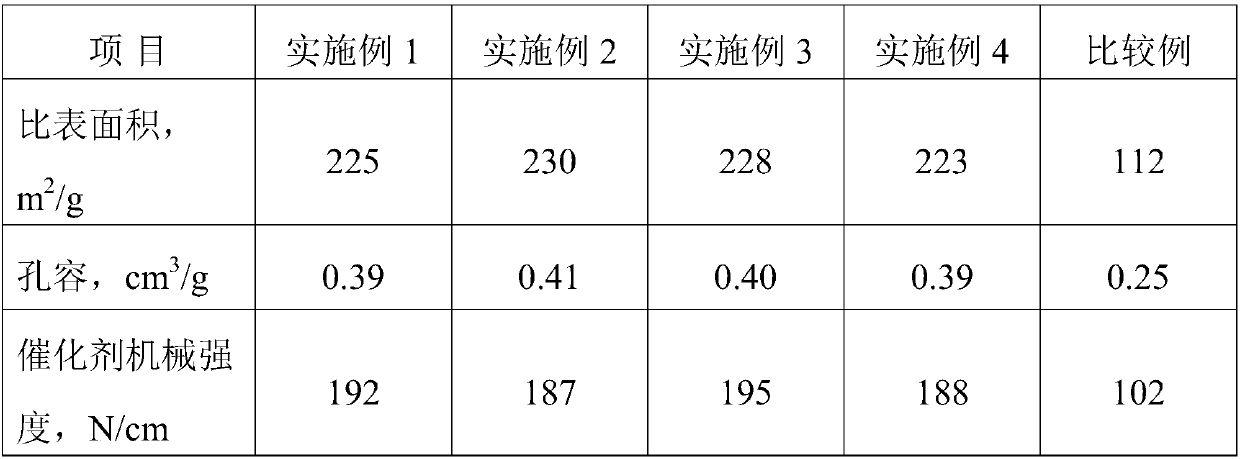

Embodiment 1

[0053] Add deionized water dropwise to potassium titanate at a mass ratio of 1.5:1, stir evenly, seal and let stand for 7 days to obtain a sample; disperse the above sample into excess water to make a solid-liquid ratio of 1:300, Add hydrochloric acid dropwise to adjust the pH of the solution to 2, and stir for 24 hours to carry out ion exchange; settle the exchanged emulsion, suction filter, and dry to obtain dititanic acid; immerse dititanic acid in a 15wt% KOH aqueous solution for secondary ion exchange Exchange, stand for 12h, filter and dry to obtain mesoporous TiO 2 Whiskers, specific surface area 119m 2 / g, pore volume 0.28cm 3 / g, the most probable pore diameter is 9nm.

[0054] Pseudoboehmite and mesoporous TiO 2 The mass ratio of the whiskers is 6:1, and deionized water is added according to the solid-to-liquid ratio of 1:30, stirred and mixed, placed in an oil bath and heated to 60°C and kept at a constant temperature; slowly drop HNO 3 Adjust the pH of the syst...

Embodiment 2

[0058] Add deionized water dropwise to potassium titanate at a mass ratio of 2:1, stir evenly, seal and let stand for 3 days to obtain the sample; disperse the above sample into excess water to make the solid-liquid ratio 1:400, Add hydrochloric acid dropwise to adjust the pH of the solution to 3, and stir for 20 hours to carry out ion exchange; the exchanged emulsion is sedimented, suction filtered, and dried to obtain dititanic acid; immerse dititanic acid in a 30wt% KOH aqueous solution for secondary ion exchange Exchange, stand for 8h, filter and dry to obtain mesoporous TiO 2 Whiskers, specific surface area 121m 2 / g, pore volume 0.30cm 3 / g, the most probable pore size is 10nm.

[0059] Pseudoboehmite and mesoporous TiO 2 The mass ratio of whiskers is 9:1, and deionized water is added according to the solid-to-liquid ratio of 1:25, stirred and mixed, placed in an oil bath and heated to 90°C and kept at a constant temperature; slowly drop HNO 3 Adjust the pH of the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com