A kind of UV/moisture dual fast curing polysiloxane adhesive composition

A polysiloxane, fast-curing technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of slow molecular chain growth, low hydrolysis activity, and difficulty in obtaining, and achieve Low polar solvent content, excellent weather resistance, and large curing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

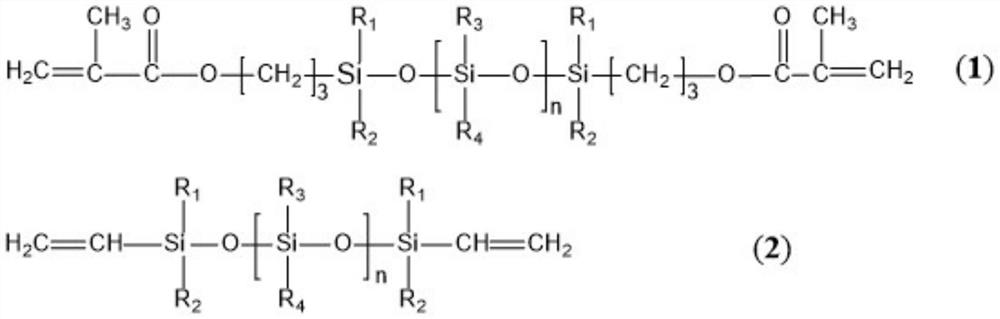

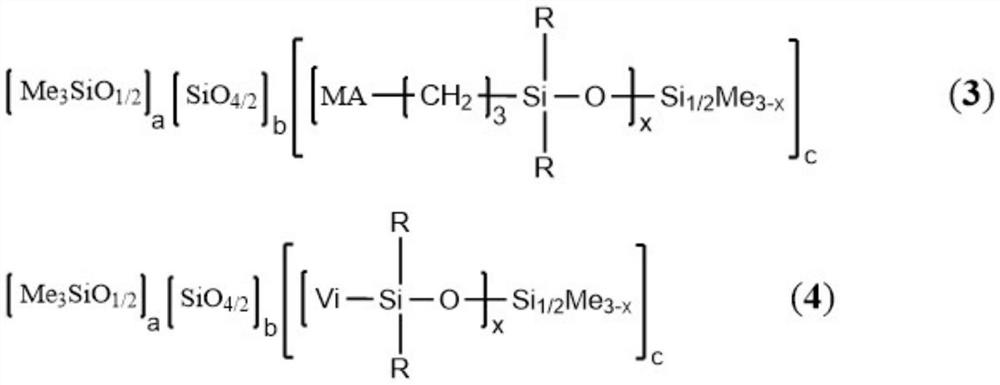

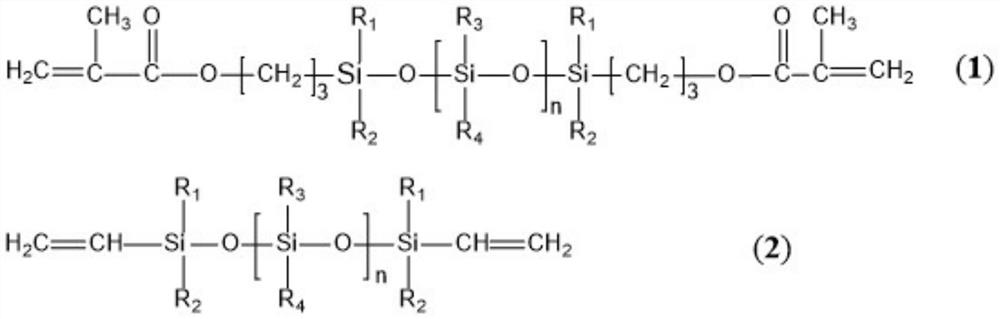

Image

Examples

Embodiment 1

[0062] Mix 100 parts under vacuum at 120°C with a viscosity of 80,000mPa.S for 2 hours, cool down to below 35°C, add 2 parts of methacryloxypropyl triacetoxysilane, 0.1 part of dibutyltin dilaurate, under vacuum conditions Mixed for 2 hours, sealed with a moisture-proof material and packaged to obtain diorgano-modified polysiloxane MATPM-80K.

Embodiment 2

[0064] Mix 100 parts under vacuum at 120°C, the viscosity is 80000mPa.S for 2 hours, cool down to below 35°C, add 2 parts of vinyltriacetoxysilane, 0.1 part of dibutyltin dilaurate, and mix under vacuum for 2 hours , packaged with a moisture-proof sealing material to obtain diorgano-modified polysiloxane VTPM-80K.

Embodiment 3

[0066] After vacuum mixing 100 parts of dihydroxy-terminated polydimethylsiloxane with a viscosity of 20 mPa.S at 120°C for 2 hours, the temperature was lowered to below 35°C, and 180 parts of methacryloxypropyltriacetoxy Silane and 0.4 parts of dibutyltin dilaurate were mixed for 2 hours under vacuum conditions, and packed with a moisture-proof sealing material to obtain diorgano-modified polysiloxane MATPM-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com