Low-shrinkage adhesive film for solar cell packaging and preparation method of adhesive film

A solar cell, low shrinkage technology, applied in chemical instruments and methods, applications, circuits, etc., can solve the problems of backplane deformation, thermal shrinkage cannot meet the dimensional stability requirements of through holes, low water vapor transmission, etc. The effect of excellent weather resistance and excellent other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The low-shrinkage MWT solar cell encapsulating adhesive film includes PVB film, PET film and PVB film from top to bottom, and the preparation method is as follows: the PVB film, PET film and PVB film are combined by melting lamination, and the composite film is Two-way stretching, the transverse stretching ratio is 2.5 times, the longitudinal stretching ratio is 3.0 times, after cooling, the far-infrared heating is carried out to 230°C for two longitudinal stretching, the first longitudinal stretching ratio is 2.0 times, and the second longitudinal stretching ratio is 2.0 times. The draw ratio is 1.5 times, the thickness of the PVB film in the prepared composite adhesive film is 0.2mm, and the thickness of the PET film is 0.07mm.

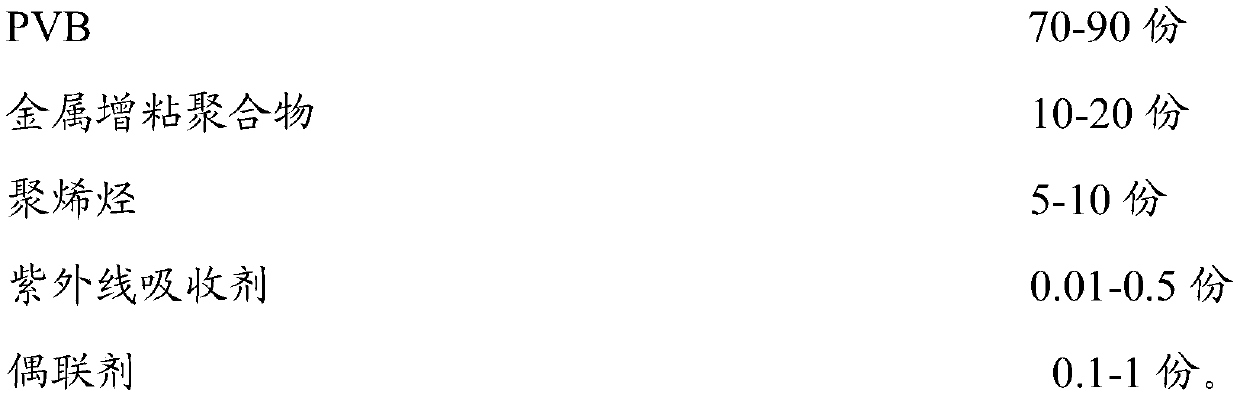

[0023] The raw materials of the PVB film are composed of the following components in parts by weight, and the components are blended and cast into a film through a twin-screw extruder.

[0024]

[0025]

Embodiment 2

[0027] The low-shrinkage MWT solar cell encapsulating adhesive film includes PVB film, PET film and PVB film from top to bottom, and the preparation method is as follows: the PVB film, PET film and PVB film are combined by melting lamination, and the composite film is Two-way stretching, the transverse stretching ratio is 2.5 times, the longitudinal stretching ratio is 3.0 times, after cooling, the far-infrared heating is carried out to 230°C for two longitudinal stretching, the first longitudinal stretching ratio is 2.0 times, and the second longitudinal stretching ratio is 2.0 times. The draw ratio is 1.5 times, the thickness of the PVB film in the prepared composite adhesive film is 0.35mm, and the thickness of the PET film is 0.03mm.

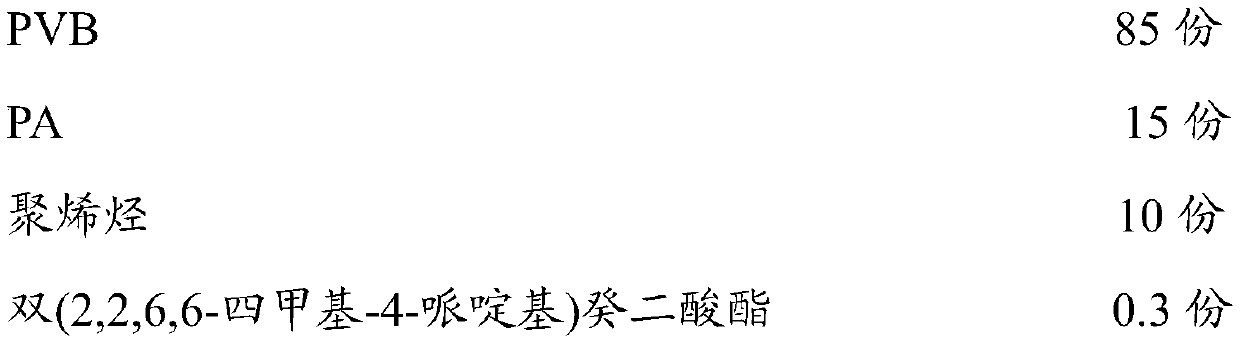

[0028] The raw materials of the PVB film are composed of the following components in parts by weight, and the components are blended and cast into a film through a twin-screw extruder.

[0029]

Embodiment 3

[0031] The difference from Example 1 is that the PET film is biaxially stretched before compounding, and the transverse and longitudinal stretching ratios are 2.5 times, and then laminated and compounded, and then the composite film is longitudinally stretched twice, the first The secondary longitudinal stretch ratio is 3.0 times, and the second longitudinal stretch ratio is 2.0 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com