Exhaust gas recovery and utilization method for producing liquefied natural gas from coke oven gas

A technology for liquefied natural gas and coke oven gas, which is applied in gas/liquid distribution and storage, gas fuel, petroleum industry, etc., can solve problems such as energy waste, large fluctuation of gas composition, and inability to achieve stable production in production processes, and achieves a reduction in energy consumption. The effect of low production cost, retrofit cost, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

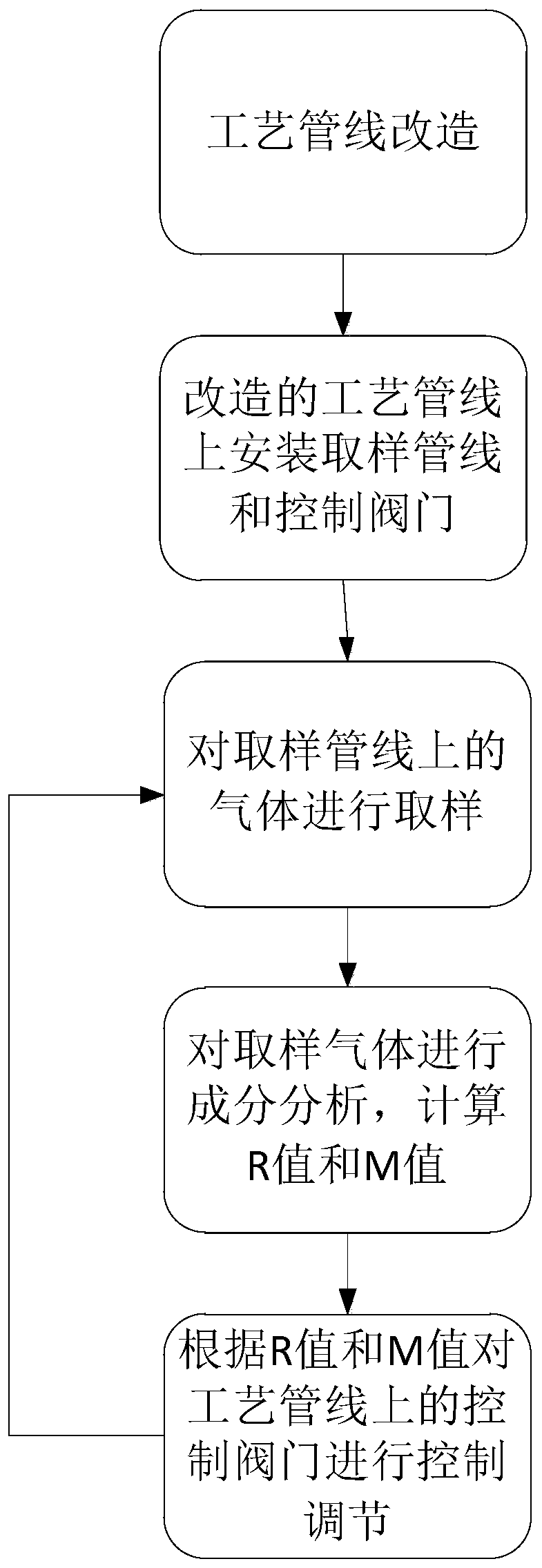

[0025] like Figure 1~2 Shown:

[0026] A tail gas recycling method for coke oven gas production of liquefied natural gas, characterized in that it comprises the following steps:

[0027] S1: In the process of producing liquefied natural gas from coke oven gas, the nitrogen and hydrogen tail gas separated and discharged from the top of the dehydrogenation tower and rectification tower are divided into two paths; one path is connected to the flare venting pipeline, and a control valve V1 is installed; the other path It is connected to the gas supply pipeline of coke oven gas, and the control valves V2, PV-0606, V3 are installed in series on the pipeline; among them, any one of the three valves V2, PV-0606, V3 The switch of the pipeline can be controlled separatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com