A kind of glass fiber reinforced nylon composite material and its preparation method and application

A nylon composite material and glass fiber technology, applied in the field of glass fiber reinforced nylon composite material and its preparation, can solve problems such as long time, and achieve the effects of short processing time, good compatibility and promoting dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

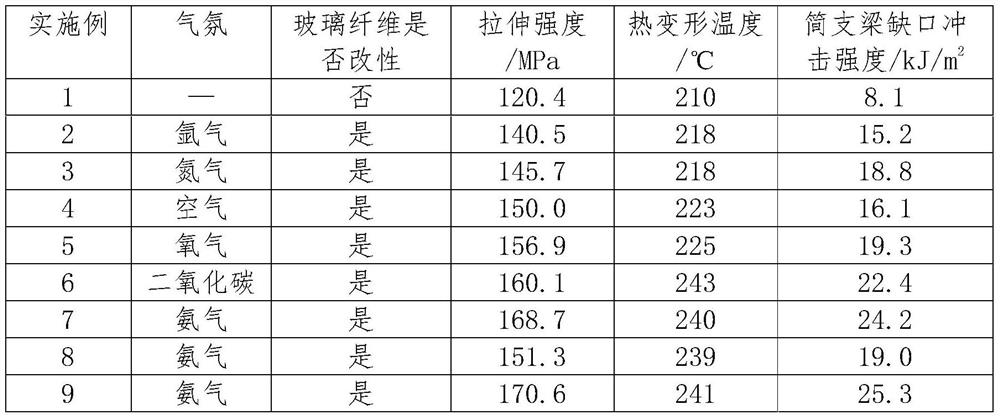

Examples

Embodiment 1

[0038] A preparation method of glass fiber reinforced nylon composite material, comprising the following steps:

[0039] (1) Weigh 30 parts of glass fiber and 2 parts of silane coupling agent (KH550) into a high-speed mixer, stir for 30 minutes, raise the temperature to 80°C and continue stirring for 1 hour, and the obtained product is ready for use.

[0040] (2) take by weighing 57 parts of nylon, 10 parts of maleic anhydride grafted POE, 0.5 part of calcium stearate, 0.5 part of antioxidant 1098, mix these several kinds of raw materials in a high-speed mixer for 30min, and then mix the obtained The material and the product obtained in step (1) are put into the extruder hopper together, and between 270 ° C and 320 ° C, the main screw speed is 400 rpm, the feeding screw speed is 30 rpm, and the side feeding screw speed is 100 rpm. The extrusion is carried out under the condition of rev / min, and the extrudate is subjected to pulling (pulling speed 8 m / min), cooling (cooling tem...

Embodiment 2

[0042] A preparation method of glass fiber reinforced nylon composite material, comprising the following steps:

[0043] (1) take by weighing 30 parts of glass fiber and put into low temperature plasma reaction device, feed argon gas as plasma, gas pressure 500Pa, radio frequency discharge power 400W, discharge time 20min, obtain modified glass fiber, for subsequent use.

[0044] (2) take by weighing 57 parts of nylon, 10 parts of maleic anhydride grafted POE, 0.5 part of calcium stearate, 0.5 part of antioxidant 1098, mix these several kinds of raw materials in a high-speed mixer for 30min, and then mix the obtained The material and the product obtained in step (1) are put into the extruder hopper together, and between 270 ° C and 320 ° C, the main screw speed is 400 rpm, the feeding screw speed is 30 rpm, and the side feeding screw speed is 100 rpm. The extrusion is carried out under the condition of rev / min, and the extrudate is subjected to pulling (pulling speed 8 m / min),...

Embodiment 3

[0046] A preparation method of glass fiber reinforced nylon composite material, comprising the following steps:

[0047] (1) take by weighing 30 parts of glass fiber and put into low temperature plasma reaction device, feed nitrogen as plasma, gas pressure 500Pa, radio frequency discharge power 400W, and discharge time 20min, obtain modified glass fiber, for subsequent use.

[0048] (2) take by weighing 57 parts of nylon, 10 parts of maleic anhydride grafted POE, 0.5 part of calcium stearate, 0.5 part of antioxidant 1098, mix these several kinds of raw materials in a high-speed mixer for 30min, and then mix the obtained The material and the product obtained in step (1) are put into the extruder hopper together, and between 270 ° C and 320 ° C, the main screw speed is 400 rpm, the feeding screw speed is 30 rpm, and the side feeding screw speed is 100 rpm. The extrusion is carried out under the condition of rev / min, and the extrudate is subjected to pulling (pulling speed 8 m / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com