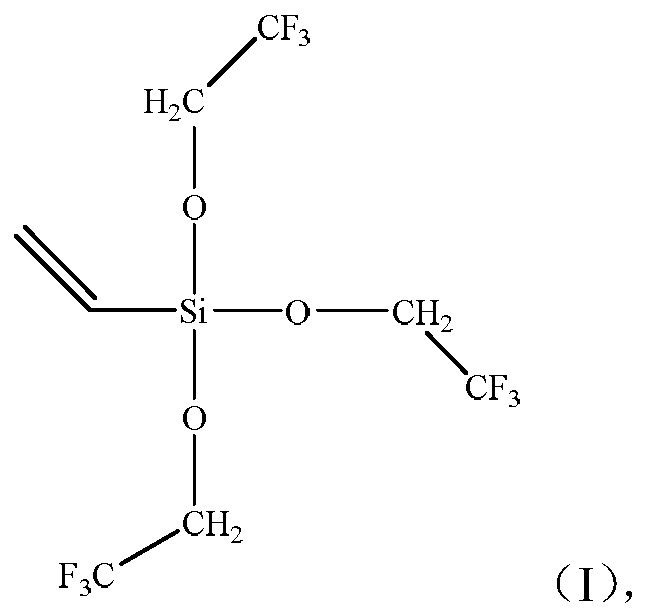

Method for preparing vinyl tri(2,2,2-trifluoroethoxy) silane

A technology of vinyltrichlorosilane and trifluoroethoxy, which is applied in the field of preparation of vinyltrisilane, can solve the problems of increasing the difficulty of product separation, low single-pot output, and low economic benefits, and achieves easy industrial production and equipment The effect of less investment and high utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

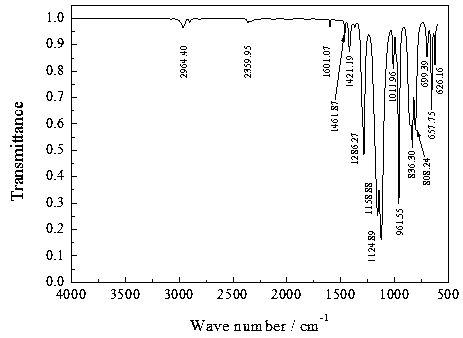

Image

Examples

Embodiment 1

[0029] (1) Add 48.6g (0.3mol) of vinyl trichloride into a 250mL three-necked flask equipped with a thermometer, a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, a bottom tube bubbling device, and an HCl tail gas absorption device. Chlorosilane, a cooling medium at -30°C was introduced into the reflux condenser, the temperature of the material in the three-necked flask was raised to 50°C, and 105g (1.05mol) of trifluoroethanol was added dropwise to the three-necked flask at a constant speed through a constant pressure dropping funnel, It took 60 minutes and the dropping rate was 1.75g / min. After the dropwise addition of trifluoroethanol is completed, the materials in the three-necked flask are maintained at 50°C for 60 minutes; Put it into a three-necked flask to take away the generated HCl gas, and discharge it after being neutralized by the tail gas absorption device. After the material is kept in the reflux state and the blowing and purging stat...

Embodiment 2

[0032](1) Add 48.6g (0.3mol) of vinyl trichloride into a 250mL three-necked flask equipped with a thermometer, a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, a bottom tube bubbling device, and an HCI tail gas absorption device. Chlorosilane, a cooling medium at -20°C was introduced into the reflux condenser, and after the material in the three-necked flask was lowered to -20°C, 90g (0.90mol) of trifluoroethanol was dropped into the three-necked flask at a constant speed through a constant pressure dropping funnel In the process, it took 180min and the dropping rate was 0.5g / min. After the dropwise addition of trifluoroethanol is completed, the materials in the three-necked flask are maintained at -20°C for 90 minutes; Put it into a three-necked flask to take away the generated HCl gas, and discharge it after being neutralized by the tail gas absorption device. After the material is kept in the reflux state and blowing and purging state for 4 hou...

Embodiment 3

[0035] (1) Add 48.6g (0.3mol) of vinyl trichloride into a 250mL three-necked flask equipped with a thermometer, a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, a bottom tube bubbling device, and an HCl tail gas absorption device. Chlorosilane, a cooling medium at -10°C was introduced into the reflux condenser, and after the material in the three-neck flask was raised to 60°C, 97.5g (0.975mol) of trifluoroethanol was added dropwise at a constant speed to the three-necked flask through a constant pressure dropping funnel In the flask, it took 60min and the rate of addition was 1.63g / min. After the dropwise addition of trifluoroethanol is completed, the temperature of the material in the three-necked flask is raised to reflux, and at the same time, dry nitrogen gas is sent into the three-necked flask through the bottom tube bubbling device to take away the generated HCl gas, which is absorbed by the tail gas After the device was neutralized and disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com