Transition metal chalcogen-group carbon-based heterostructure composite material with regular morphology and preparation method and application of transition metal chalcogen-group carbon-based heterostructure composite material

A transition metal, heterostructure technology, applied in the preparation/purification of carbon, structural parts, chemical instruments and methods, etc., can solve the irregular morphology of transition metal chalcogenide compounds, unstable interface structure, carbon-based composite Non-uniformity and other problems, to achieve the effect of accelerating the progress of the electrochemical reaction, improving the rate performance, and increasing the active sites of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

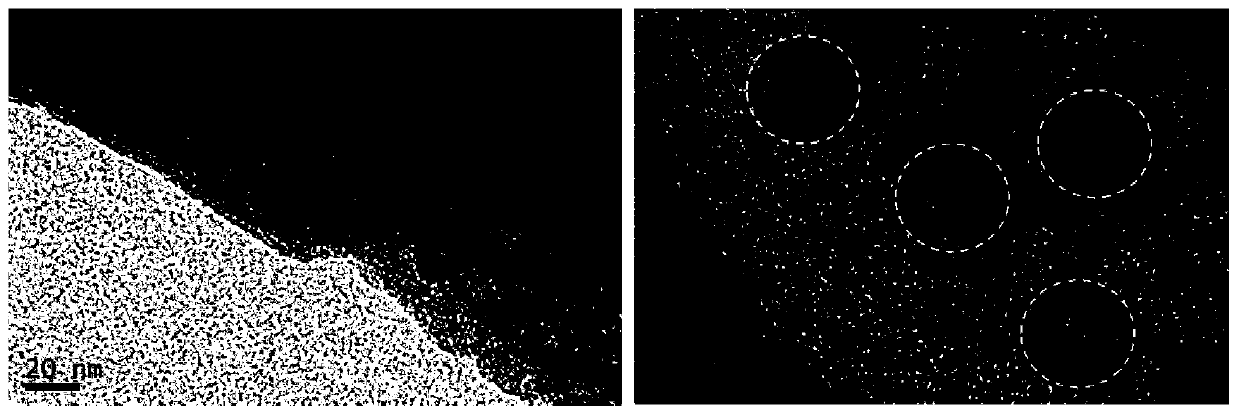

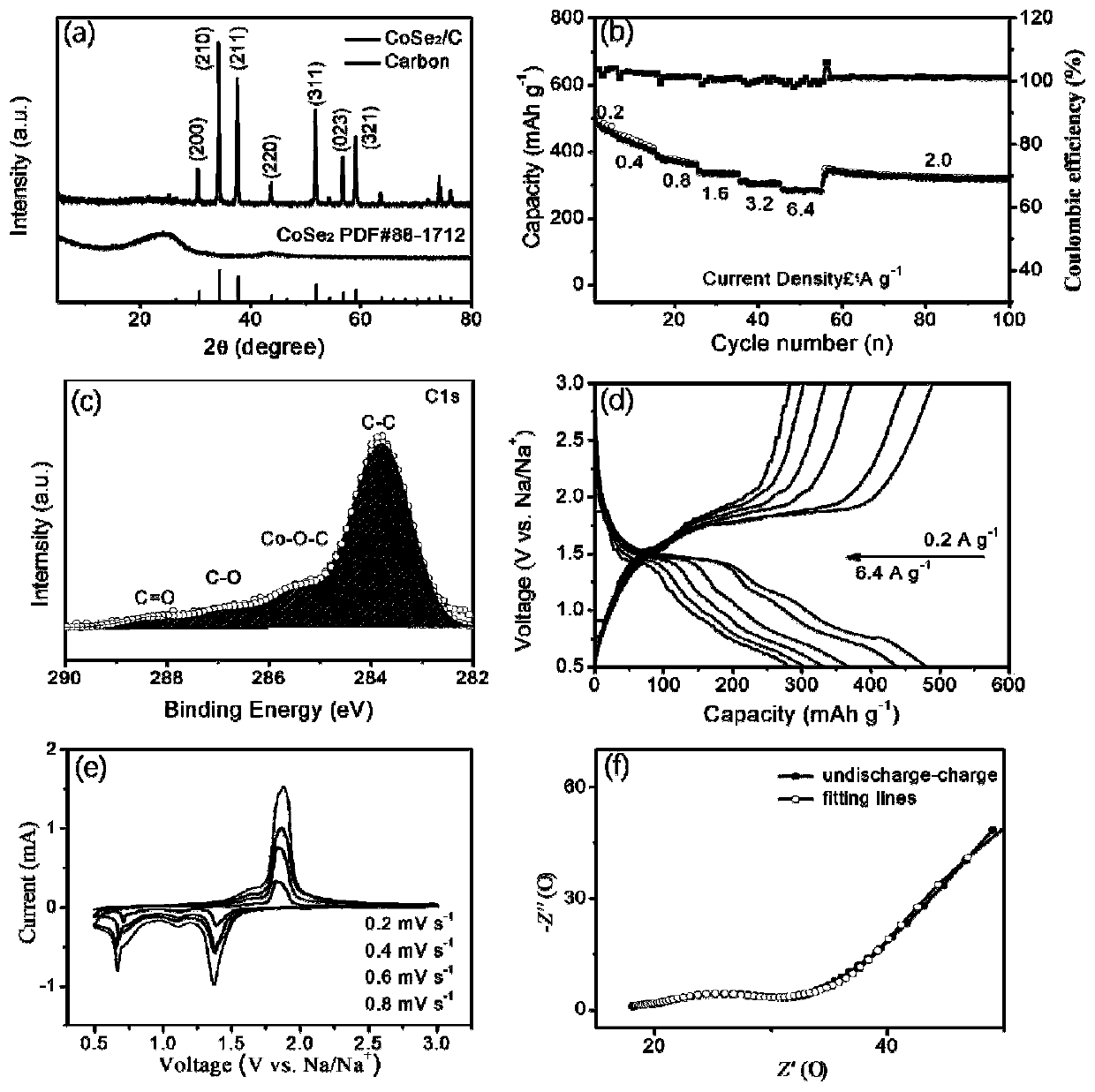

[0043] Mix 1.0 g of commercial cobalt acetylacetonate with 2.0 g of selenium powder and 3.0 g of sodium sulfate, and then calcinate it at 500 ° C for 2 h under the protection of inert gas argon, with a heating rate of 3 ° C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder That is, nanodot-like cobalt diselenide carbon-based heterostructure (CoSe 2 / C). figure 1 Based on the scanning electron microscope picture of the nano-dot-like cobalt diselenide carbon-based heterostructure, it can be observed that the carbon matrix is completely covered with the cobalt diselenide material. figure 2 The worthwhile nano-dot-like cobalt diselenide carbon-based heterostructure transmission electron microscope pictures, it ca...

Embodiment 2

[0046] Mix 1.0g of commercial cobalt acetylacetonate, 2.0g of selenium powder and 3.0g of sodium sulfate evenly, and then calcinate it at 500°C for 2h under the protection of reducing gas 5% hydrogen-argon mixed gas, and the heating rate is 3°C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder Nano-microsphere cobalt diselenide nanotube carbon-based heterostructure (CoSe 2 / C). Figure 4 It is a scanning electron microscope picture of the carbon-based heterogeneous structure of the nano-microsphere cobalt diselenide nanotube, and the particles wrapped by the carbon nanotube can be seen. Electrochemical test results show that at 5.0A g -1 Under the current density, after 5000 cycles, the sodium capacitance can ...

Embodiment 3

[0050] Mix 1.0g of commercial cobalt acetylacetonate, 2.0g of selenium powder and 3.0g of sodium sulfate evenly, and then calcinate it at 800°C for 5h under the protection of reducing gas 5% hydrogen-argon mixed gas, and the heating rate is 10°C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder That is grape microspherical cobalt selenide carbon-based heterostructure (CoSe / C). Figure 5 This is the scanning electron microscope picture of the grape microspherical cobalt selenide carbon-based heterostructure, and the nanoparticles wrapped by the carbon matrix can be seen. Electrochemical test results show that at 5.0A g -1 Under the current density, after 8000 cycles, the sodium capacitance can maintain 297mAh g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com