Method for improving nickel electroplating quality of aluminum-silicon alloy

A technology of silicon-aluminum alloy and electroplating nickel, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, anodic oxidation, etc., can solve problems such as delamination, rough coating, and blistering, and achieve manufacturing cost reduction, electroplating cost reduction, and product quality. The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

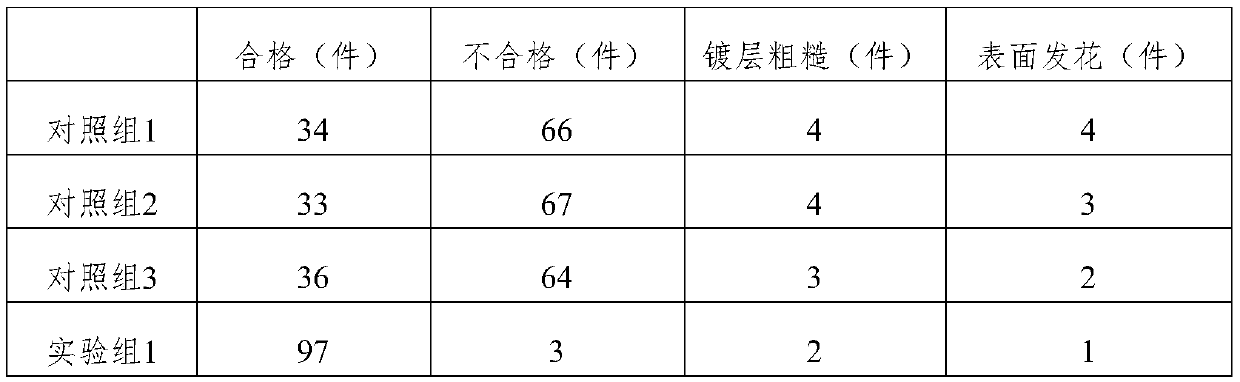

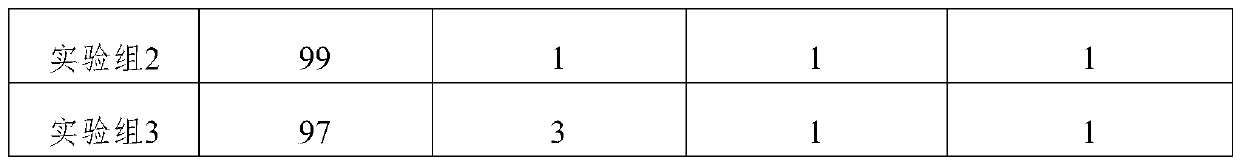

Embodiment 1

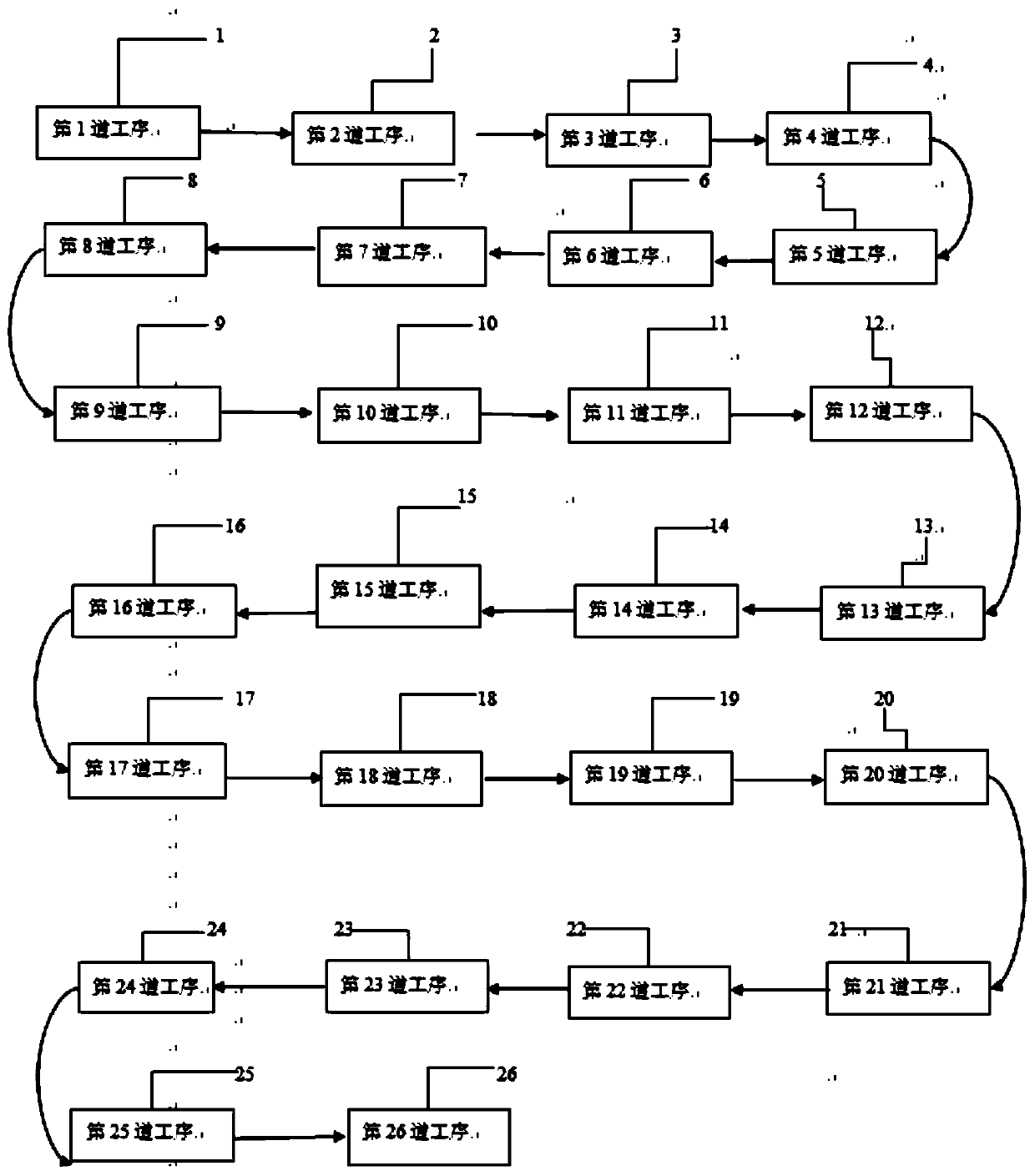

[0044] A method for improving the quality of electroplating nickel on silicon-aluminum alloys, comprising:

[0045] (1) Organic degreasing: soak the silicon-aluminum alloy in an organic solvent, wash at 50°C for 15 minutes, and dry the silicon-aluminum alloy for later use; the organic solvent is composed of turpentine and gasoline with a mass ratio of 3:1;

[0046] (2) Cleaning: Rinse the silicon-aluminum alloy in clean water at room temperature for 1-15 minutes;

[0047] (3) Electrolytic degreasing: use tungsten carbide-based hard alloy as the cathode, and silicon-aluminum alloy as the anode, and put it into the electrolyte solution for electrolytic degreasing for 5 minutes. The formula of the electrolyte is tripotassium phosphate 80g / L, acetic acid 20g / L, potassium hydroxide 5g / L, sodium sulfate 10g / L, and the balance is water; the electrolysis conditions are: temperature 55°C, current density 8A / dm 2 ;

[0048] (4) Drying: bake the silicon-aluminum alloy at 60°C and 0.1 s...

Embodiment 2

[0072] A method for improving the quality of electroplating nickel on silicon-aluminum alloys, comprising:

[0073] (1) Organic degreasing: soak the silicon-aluminum alloy in an organic solvent, wash at 55° C. for 15 minutes, and dry the silicon-aluminum alloy for later use; the organic solvent is composed of turpentine and gasoline with a mass ratio of 3:1;

[0074] (2) Cleaning: Rinse the silicon-aluminum alloy in clean water at room temperature for 1 min;

[0075] (3) Electrolytic degreasing: use tungsten carbide-based hard alloy as the cathode, and silicon-aluminum alloy as the anode, and put it into the electrolyte solution for electrolytic degreasing for 8 minutes. The formula of the electrolyte is tripotassium phosphate 80g / L, acetic acid 20g / L, potassium hydroxide 5g / L, sodium sulfate 10g / L, and the balance is water; the electrolysis conditions are: temperature 55°C, current density 8A / dm 2 ;

[0076] (4) Drying: bake the silicon-aluminum alloy at 65°C and 0.2 standa...

Embodiment 3

[0100] Implement according to the steps of Example 2, but the step (21) pre-nickeling is changed to: put the silicon-aluminum alloy into the alkaline pre-nickeling solution for pre-nickeling, at a temperature of 26° C., pre-plating for 5 minutes; the pre-nickeling The solution formula is: nickel chloride 19g / L, sodium hypophosphite 20g / L, sodium pyrophosphate 30g / L, sodium citrate 3g / L, potassium hydroxide 6g / L; other operating measures are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com