Preparation and application of waterborne polyurethane emulsion

A water-based polyurethane and emulsion technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of restricting the production and market application of water-based polyurethane coatings, unfavorable large-scale commercial promotion and application, poor water resistance and chemical resistance, etc. , to achieve the effect of simple preparation method, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

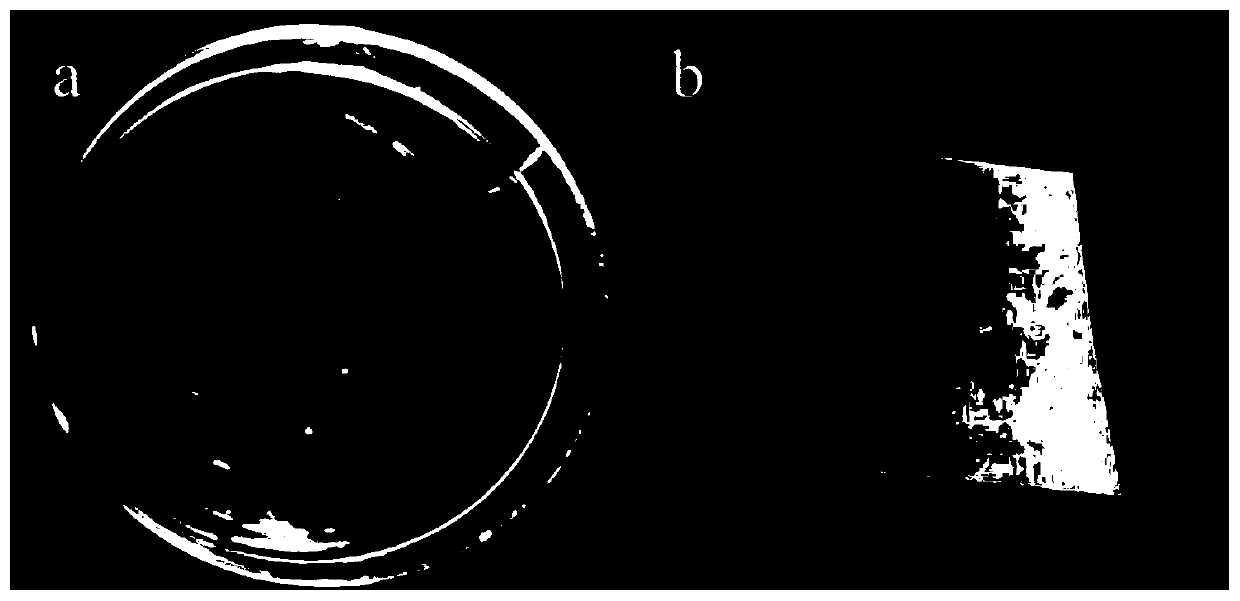

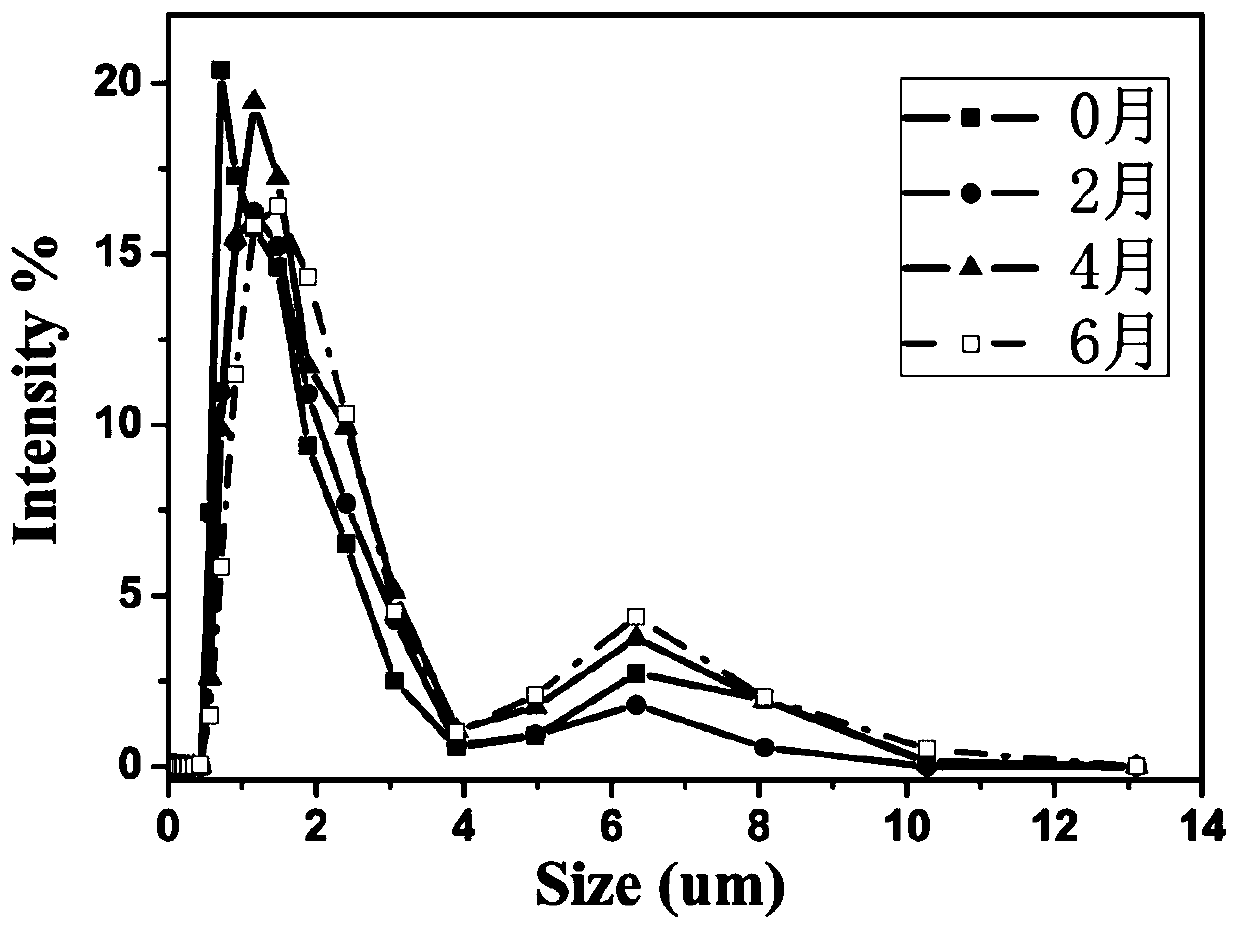

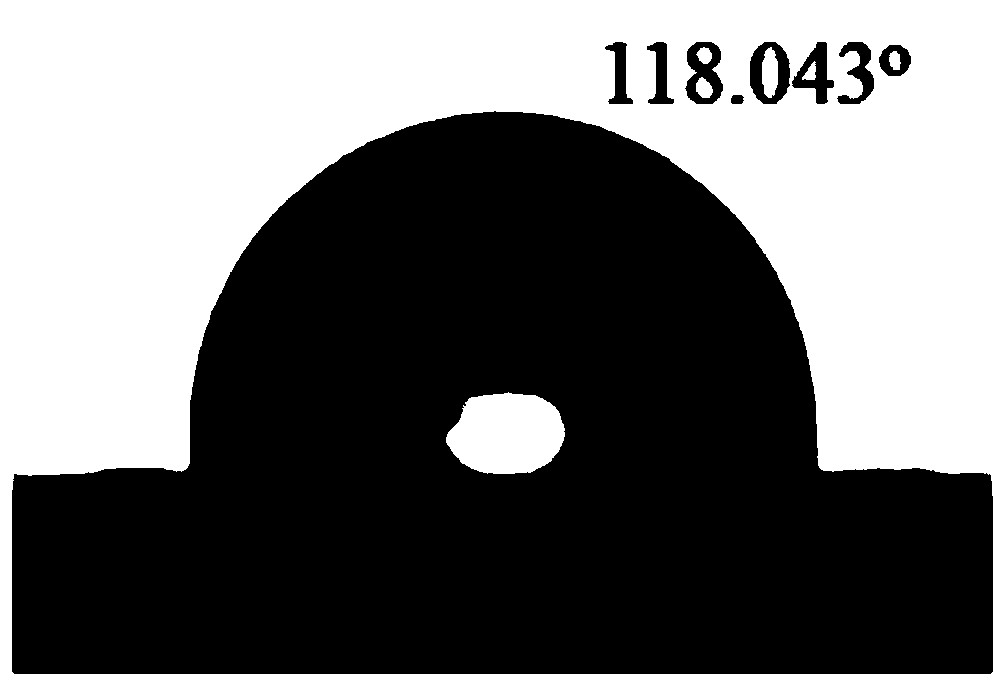

Image

Examples

Embodiment 1

[0027] HMDI and IPDI are mixed in a molar ratio of 2:1 to form a mixture A, PCDL and PCL are mixed in a molar ratio of 2:1 to form a mixture B, and mixture A and mixture B are mixed to form a reaction solution, and -NCO and -OH in the reaction solution The molar ratio is 5:1; add 5.5wt% DMPA to the reaction solution, react at 85°C for 2.5 hours; adjust the temperature to 65°C, add 35wt% acetone to adjust the viscosity, add 2.5wt% TMP, and react for 5 hoursn When -NCO reaches the theoretical value of 1.8%, add DMEA to neutralize -COOH in DMPA to form a waterborne polyurethane prepolymer; the molar ratio of DMEA to DMPA is 1.13:1;

[0028] The prepared water-based polyurethane prepolymer was added to the deionized water accounting for 65wt% of the total mass of the system under 3000 rpm high-speed stirring state and stirred for 0.5 hours, and 1.9wt% ethylenediamine was added at room temperature and stirred for 3 hours to obtain a water-based polyurethane dispersion;

[0029] The...

Embodiment 2

[0038] Mix HMDI and IPDI at a molar ratio of 1:0.01 to form mixture A, mix PCDL and PCL at a molar ratio of 1:1 to form mixture B, mix mixture A and mixture B to form a reaction solution, and -NCO and -OH in the reaction solution The molar ratio is 5:1; add 4.5wt% DMPA to the reaction solution, react at 95°C for 1.5 hours, adjust the temperature to 70°C, add 20wt% acetone and 0.5wt% TMP, react for 5 hours n-NCO When the theoretical value reaches 1.9%, add DMEA to neutralize -COOH in DMPA to form a waterborne polyurethane prepolymer; the molar ratio of DMEA to DMPA is 1.1:1;

[0039] The prepared water-based polyurethane prepolymer was added to the deionized water accounting for 75wt% of the total mass of the system under 1500 rpm high-speed stirring state and stirred for 0.5 hours, and 2.5wt% ethylenediamine was added at room temperature and stirred for 1.5 hours to obtain a water-based polyurethane dispersion;

[0040] The acetone in the aqueous polyurethane dispersion was re...

Embodiment 3

[0042]Mix HMDI and IPDI at a molar ratio of 2:1 to form mixture A, PCDL and PCL are mixed at a molar ratio of 1:0.01 to form mixture B, mix mixture A and mixture B to form a reaction solution, and -NCO and -OH in the reaction solution The molar ratio is 5:1; add 6.5wt% of DMPA to the reaction solution, react at 65°C for 4 hours; keep the temperature at 65°C and add acetone and TMP, acetone and TMP account for 40wt% and 3.5wt of the total mass respectively %, when n-NCO reaches the theoretical value (1.8-2.0%) after 4.5 hours of reaction, add DMEA to neutralize -COOH in DMPA to form a waterborne polyurethane prepolymer; the molar ratio of DMEA to DMPA is 1.15:1;

[0043] The prepared water-based polyurethane prepolymer was added to the deionized water accounting for 70wt% of the total mass of the system under 3500 rpm high-speed stirring state and stirred for 1 hour, and 1.4% ethylenediamine was added at room temperature and stirred for 3.5 hours to obtain a water-based polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com