Sulfydryl functional active carbon preparation method and mercury removal adsorbent

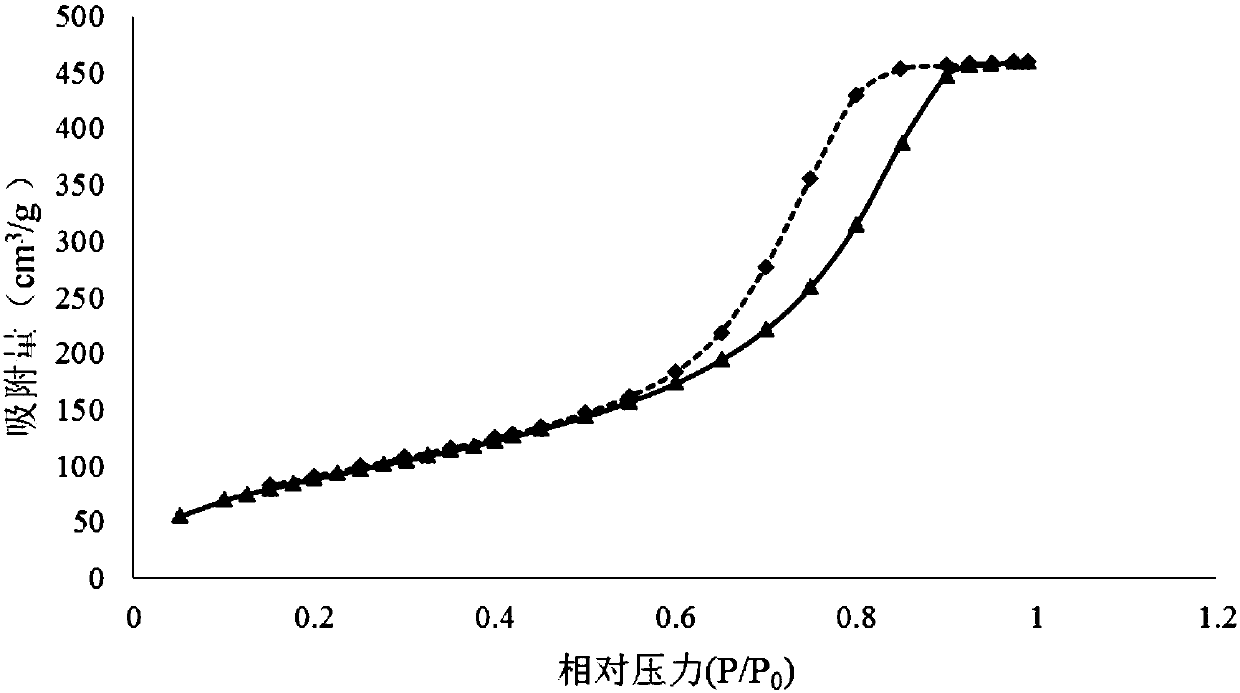

An activated carbon and functional technology, applied in the field of heavy metal adsorption, can solve the problems of reducing adsorption amount, reducing sulfhydrylation rate, pore blockage, etc., achieving the effect of strong mercury adsorption capacity, avoiding self-hydrolysis reaction and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] First, add 10g of coal-based activated carbon into 50g of γ-mercaptopropyltrimethoxysilane n-heptane solution, add 0.3g of methyl titanate as a catalyst, and react at 100°C for 2h. After the reaction, the reaction product is heated at 150 ℃, cooled, washed, and dried to obtain the finished activated carbon adsorbent, namely sulfhydryl functional activated carbon, marked as 1#.

Embodiment 2

[0054] First, add 5g of coconut shell activated carbon into 50g of γ-mercaptopropyltrimethoxysilane toluene solution, add 0.2g of butyl titanate as a catalyst, and react at 80°C for 8h. After the reaction, the reaction product is pumped at 150°C. Drying, cooling, washing, and drying, the finished product activated carbon adsorbent is obtained, i.e. sulfhydryl functional activated carbon, marked as 2#.

Embodiment 3

[0056] First, add 5g of coconut shell activated carbon to 50ml of chloroform solution containing 2.3g of γ-mercaptopropyltriethoxysilane, add 0.1g of tert-butyl titanate as a catalyst, and react at 60°C for 10h. After the reaction, the reaction product Pump dry at 150° C., cool, wash, and dry to obtain the finished activated carbon adsorbent, that is, sulfhydryl functional activated carbon, marked as 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com