Glass capable of effectively improving chemically strengthened warping performance

A glass and chemical technology, which is applied in the field of glass and its preparation for effectively improving chemically strengthened warpage performance, can solve the problems of affecting the service life of the kiln body, large environmental hazards, and corrosion of the kiln body, and achieves the improvement of chemically strengthened warpage performance. , good effect of strengthening warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

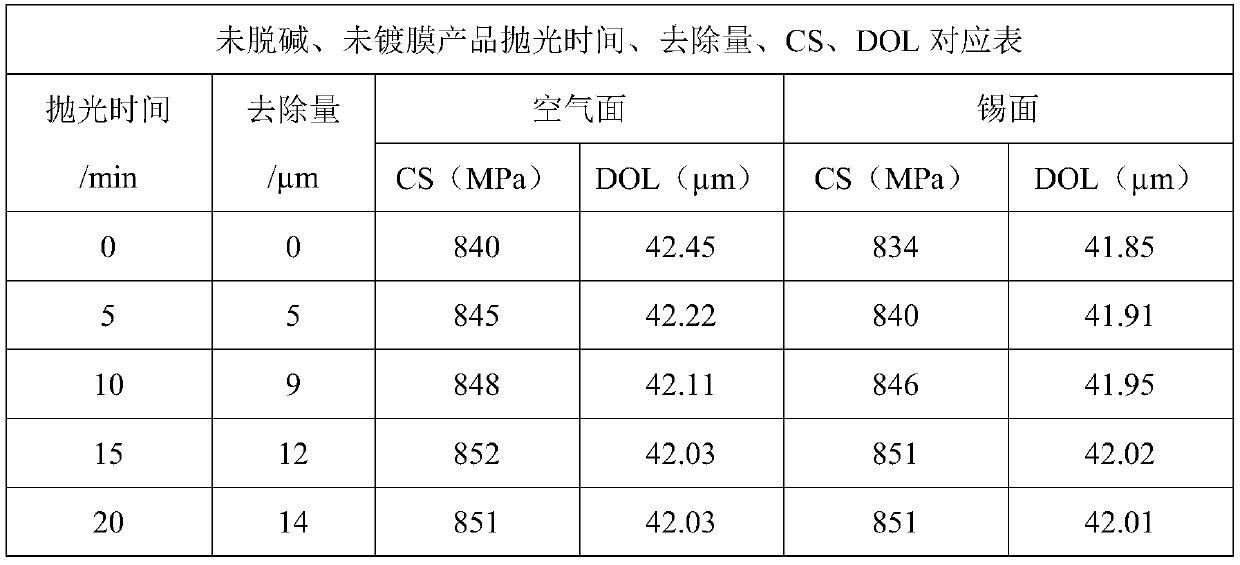

[0022] There is no special requirement for the thickness of the glass substrate, and when the chemical strengthening process is fixed, the greater the thickness, the smaller the chemical strengthening warpage, and the product with a thickness of 0.7mm is selected in the present invention.

[0023] During the glass preparation process, through tin bath process adjustment, acid treatment and annealing kiln coating control, the obtained glass has good chemically strengthened warping properties.

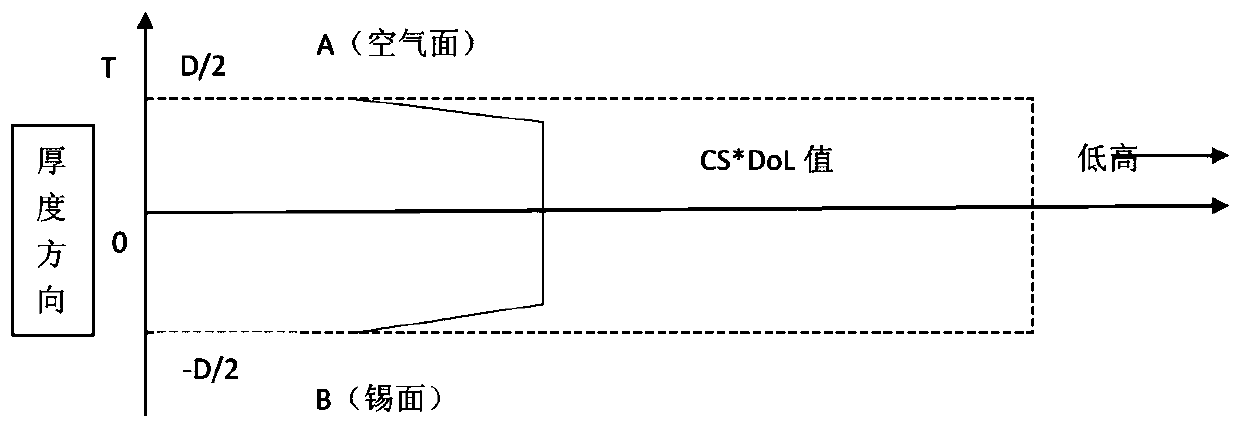

[0024] Specifically, the adjustment of the tin bath process can firstly reduce the pressure of the tin bath appropriately, increase the temperature of some areas of the tin bath, and increase the tin content in the atmosphere, and secondly adjust the composition of the tin bath protective gas, and add a certain amount of tin Steam, and pass the protective gas mixed with tin vapor into the tin bath, so that the tin in the atmosphere of the tin bath is in a supersaturated state, and a tin f...

Embodiment 2

[0041] Example 2: In this example, the principle of sol-gel coating is used to form a certain thickness of a stress-free layer on one side of the glass. At the same time, the increase in thickness will also change the geometric center of the glass, thereby improving warpage.

[0042] Experimental raw materials: 0.7mm, 2.5D products, silica sol.

[0043] Experimental process: The glass is cut, CNC, and polished to obtain a 2.5D unreinforced product, and the non-polished surface is coated with silica sol, and the silica sol is cured in an oven. Multiple batches of tests were carried out, in which the comparison sheet was not coated with silica sol, while the experimental samples were coated with silica sol. The specific data is shown in Table 5 below. From the test data, the silica sol coating is also conducive to the improvement of warpage.

[0044] table 5

[0045]

Embodiment 3

[0047] Experimental raw materials: 0.7mm product, aluminum sol suspension with a solid content of 10%.

[0048] Experimental process: Put the 300mm*300mm product into the tempering preheating furnace, heat it to 500°C, atomize the aluminum sol with a spray bottle, spray an appropriate amount of aluminum sol onto the air surface of the glass sheet, close the furnace door, and keep it warm for a period of time , cooling with furnace temperature. Then carry out CNC, cleaning, tempering and testing. The specific data are shown in Table 6 below.

[0049] Al-rich coating on one side of the glass 2 o 3 Solvent suspension forms a certain thickness of stress-free layer on one side of the glass, and the increase in thickness will also change the geometric center of the glass, thereby improving warpage.

[0050] Al plated 2 o 3 In the case of sol, the tempering warpage should theoretically increase first and then decrease, because when a small amount of Al is plated, the surface [A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com