Electrode material with porous hollow nanotube structure and preparation method thereof, negative electrode and lithium ion battery

A technology for lithium ion batteries and electrode materials, applied in the field of new energy materials, can solve the problems of lack of performance, complicated material synthesis methods, etc., and achieve the effects of improving rate performance, simple and easy-to-obtain reagents, and improving contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

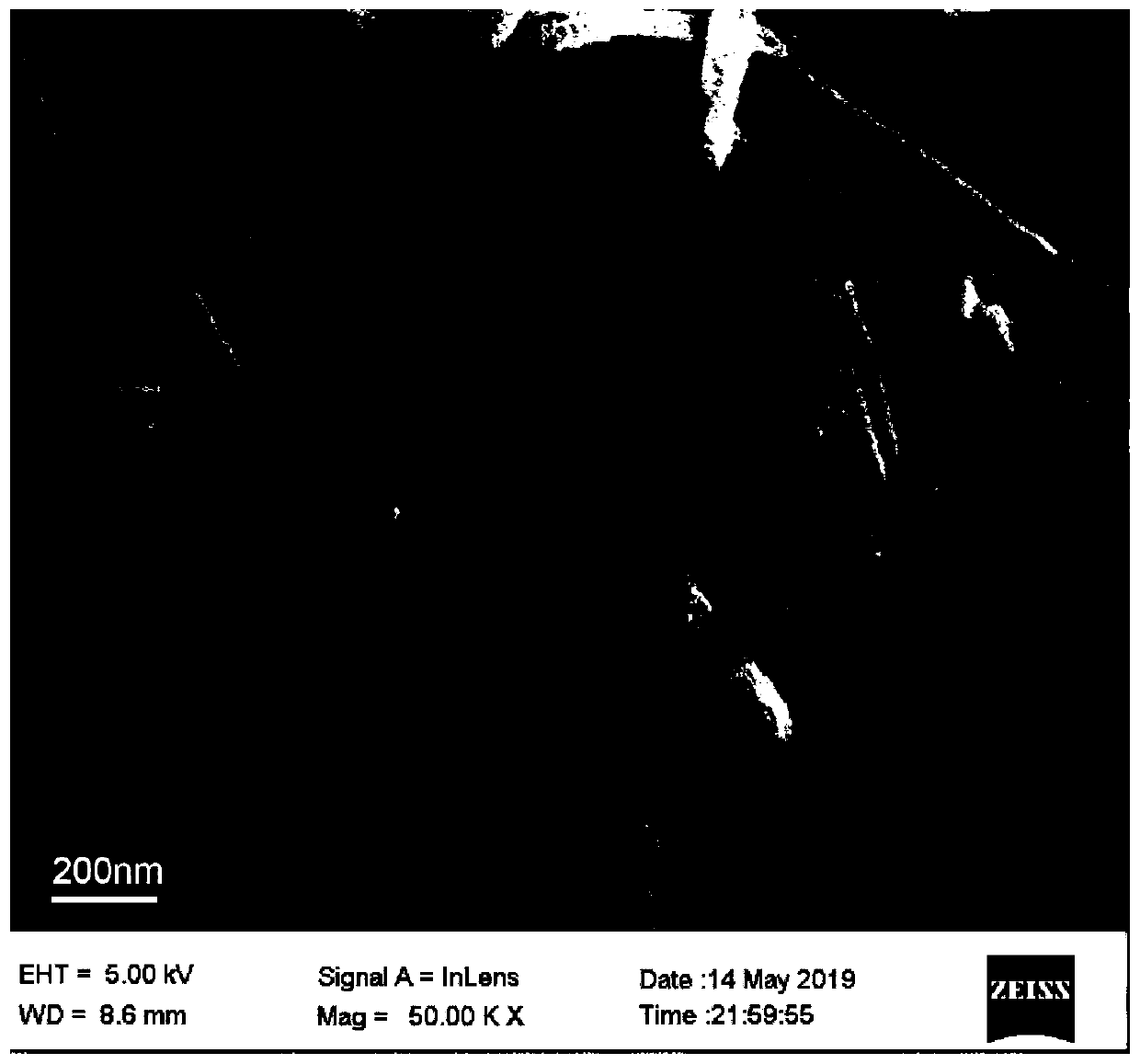

[0042] A preparation method of an electrode material with a porous hollow nanotube structure, comprising the steps of:

[0043] S1. Weigh 0.02mol Co(NO 3 )2·6H 2 O, 0.005mol PVP and 0.005mol PEO were dissolved in 30mL deionized water at the same time; in addition, 1mmol hexamethylenetetramine was added to 40mL methanol, stirred until completely dissolved, and the mixed solution of methanol and hexamethylenetetramine was dropped completely Add to the aqueous solution containing cobalt ions and continue to stir for 1h to obtain a mixed solution;

[0044]S2. Transfer the mixed solution obtained in step S1 to a 150mL round-bottom flask, reflux at 90°C for 6h, cool to room temperature after the reaction is complete, filter the reflux reaction product, and then freeze-dry at -40°C 24h, obtain precursor powder;

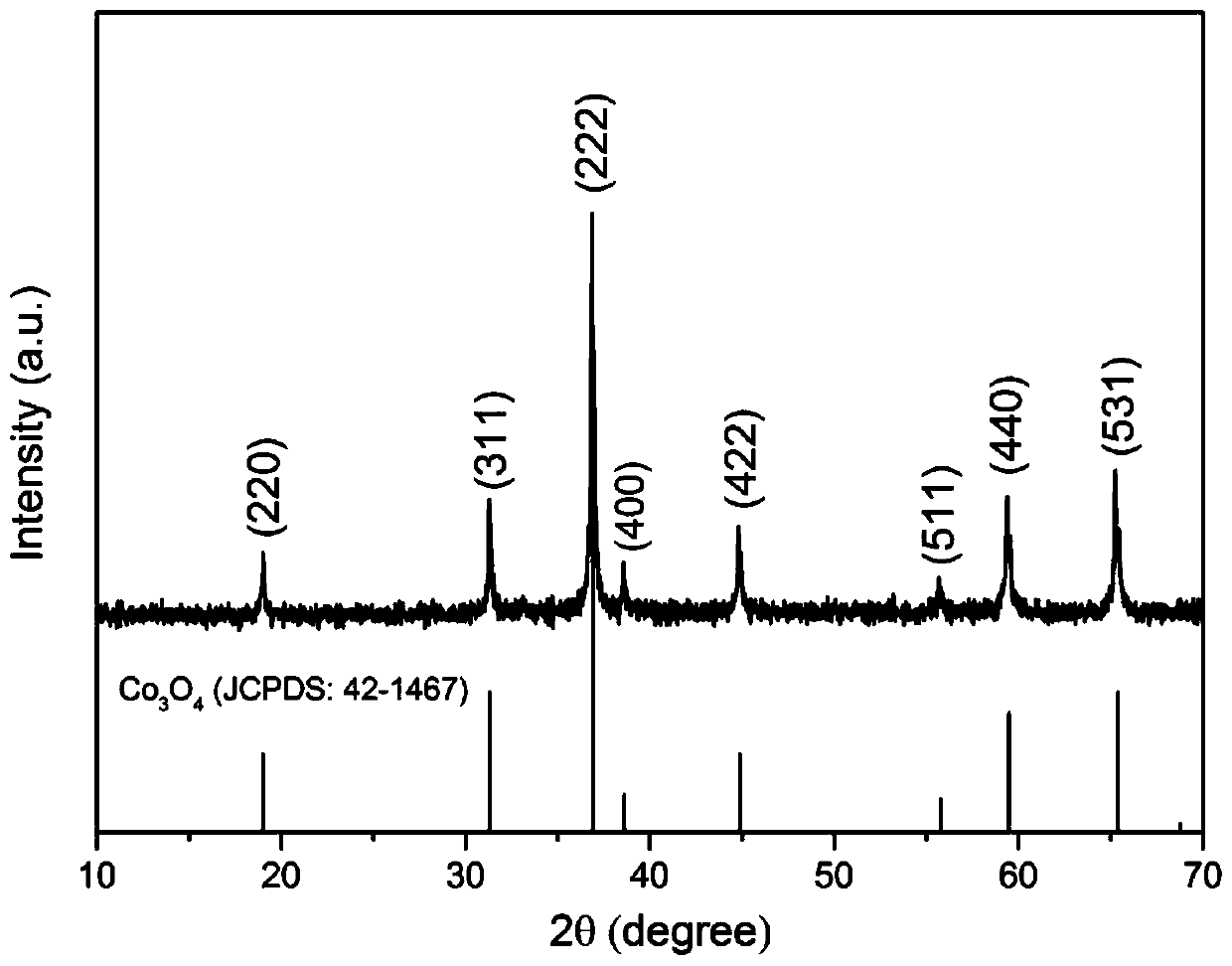

[0045] S3. Put the precursor powder prepared in step S2 into a covered porcelain crucible and transfer it to a muffle furnace, calcinate at 300°C for 180 minutes, and coo...

Embodiment 2

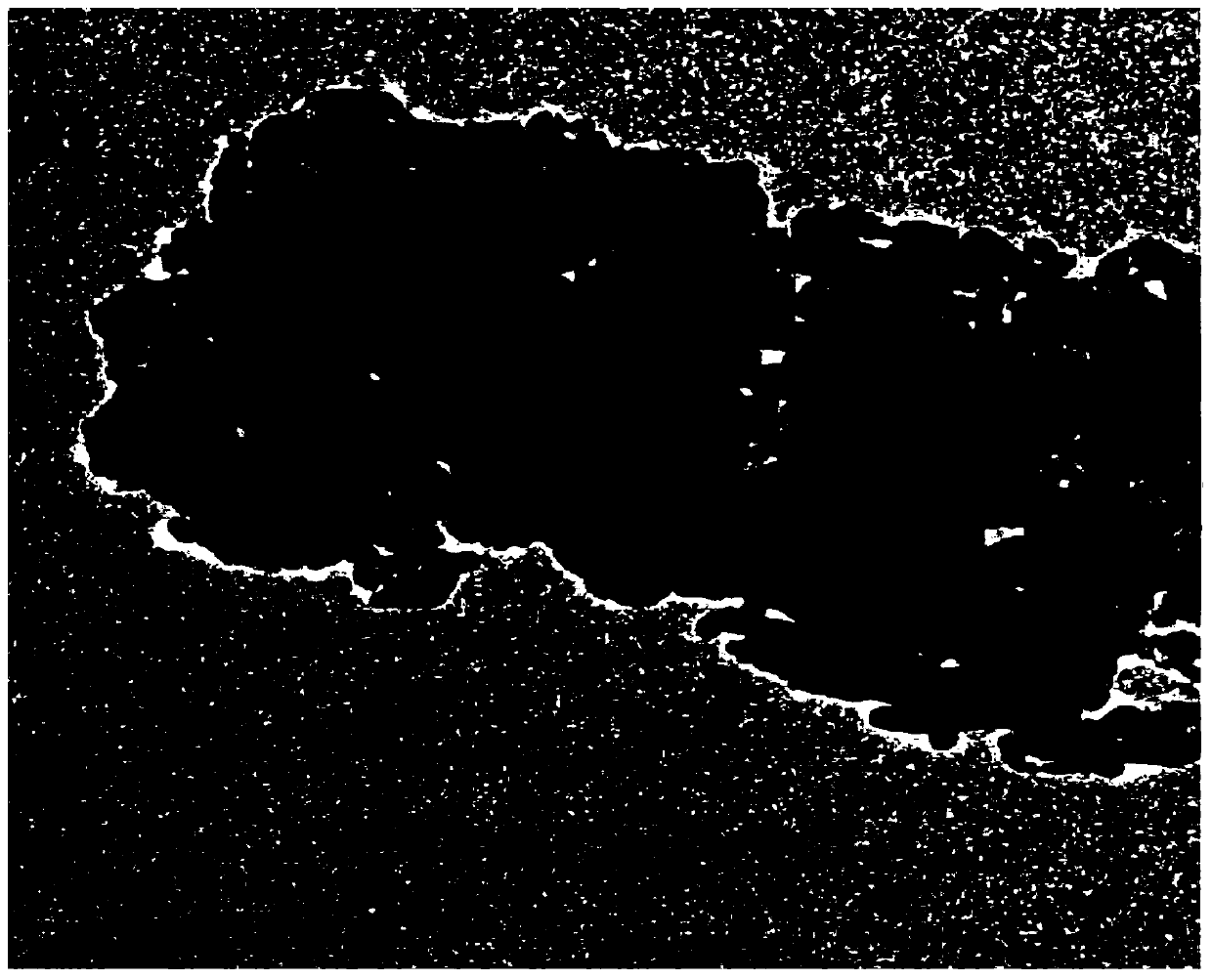

[0047] A preparation method of an electrode material with a porous hollow nanotube structure, comprising the steps of:

[0048] S1. Weigh 0.025mol Co(NO 3 ) 2 ·6H 2 O, 0.005mol PVP and 0.005mol PEO were dissolved in 30mL deionized water at the same time; in addition, 1mmol hexamethylenetetramine was added to 20mL methanol, stirred until completely dissolved, and the mixed solution of methanol and hexamethylenetetramine was dropped completely Add to the aqueous solution containing cobalt ions and continue to stir for 1h to obtain a mixed solution;

[0049] S2. Transfer the mixed solution obtained in step S1 to a 150mL round-bottomed flask, reflux at 60°C for 4h, cool to room temperature after the reaction is complete, suction filter the reflux reaction product, and then freeze-dry at -40°C 12h;

[0050] S3. Put the precursor powder prepared in step S2 into a covered porcelain crucible and transfer it to a muffle furnace, calcinate at 500°C for 60 minutes, and cool to room t...

Embodiment 3

[0052] A preparation method of an electrode material with a porous hollow nanotube structure, comprising the steps of:

[0053] S1. Weigh 0.02mol Co(CH 3 COO) 2 4H 2 O, 0.005mol PVP and 0.005mol PEO were dissolved in 30mL deionized water at the same time; in addition, 1mmol hexamethylenetetramine was added to 20mL ethanol, stirred until completely dissolved, and the mixed solution of methanol and hexamethylenetetramine was dropped completely Add to the aqueous solution containing cobalt ions and continue to stir for 1h to obtain a mixed solution;

[0054] S2. Transfer the mixed solution obtained in step S1 to a 150mL round-bottomed flask, reflux at 80°C for 6h, cool to room temperature after the reaction is complete, filter the reflux reaction product, and then freeze-dry at -40°C 12h;

[0055] S3. Put the precursor powder prepared in step S2 into a covered porcelain crucible and transfer it to a muffle furnace, calcinate at 350°C for 120 minutes, and cool to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com