Waterproof grout for tiles

A jointing agent and ceramic tile technology, which is applied in the field of building materials, can solve the problems of easy occurrence of efflorescence and poor water resistance of the jointing agent, and achieve the effects of avoiding drying shrinkage and cracking, improving water reduction effect, and preventing efflorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

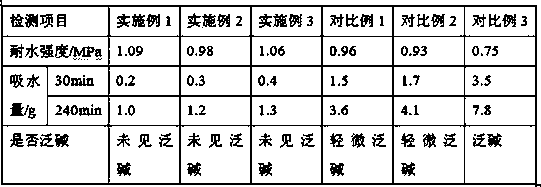

Examples

preparation example Construction

[0031]The preparation method of composite pointing base material comprises the following steps:

[0032] (1) Mix pretreated reed leaves, acetic anhydride, and sodium bisulfite solution with a mass fraction of 15% at 35~55°C according to the mass ratio of 3:1:7~12, and stir at 400~700r / min for 40 ~60min, filter, take the filter cake and dry it in an oven at 60~75°C, crush it through a 100-mesh sieve, collect the sieved matter and add additives at a mass ratio of 5~8:1 to mix, and stir magnetically at 400~700r / min for 40~60min, get pre-processed material;

[0033] (2) Take methyl vinyl silicone rubber at a mass ratio of 50~80:12:5~8, add pretreated fly ash and castor oil, mix in an open mill for 20~35min, discharge, and cool naturally to room temperature to obtain The kneaded product, in parts by mass, takes 30~50 parts of kneaded product, 20~30 parts of muscovite, 5~10 parts of basalt fiber, 15~25 parts of pretreatment material, 0.1~0.3 part of Tairan enzyme, 3~ 7 parts of di...

Embodiment 1

[0037] Pretreatment of reed leaves: Take the reed leaves and crush them through a 80-mesh sieve in a pulverizer, collect the sieved particles and add 15% NaOH solution at a mass ratio of 1:8, mix and stir for 25 minutes, filter, wash the filter residue twice with water, and dry. To obtain the dried product, take the dried product and add 12% HCl solution at a mass ratio of 1:6 to mix, filter with suction, and dry the filter residue in a freeze dryer at -10°C for 5 hours to obtain pretreated reed leaves.

[0038] Additives: Mix trimethylhexadecylammonium bromide, sodium tripolyphosphate, and sodium citrate at a mass ratio of 4:3:1 to obtain the additive.

[0039] Pretreatment of fly ash: Take fly ash and 15% sodium bicarbonate solution at a mass ratio of 1:6, mix and stir for 25 minutes, filter, take the filter residue at a mass ratio of 15:1, add silane coupling agent KH-550 and mix Grind for 1 hour to obtain pretreated fly ash.

[0040] Chain extender: Mix 1,4-butanediol and...

Embodiment 2

[0050] Pretreatment of reed leaves: take reed leaves and crush them through a 80-mesh sieve in a pulverizer, collect the sieved particles and add 15% NaOH solution at a mass ratio of 1:13, mix and stir for 45 minutes, filter, wash the filter residue with water for 4 times, and dry. To obtain the dried product, take the dried product and add 12% HCl solution at a mass ratio of 1:10 to mix, filter with suction, and take the filter residue and dry it in a freeze dryer at -10°C for 8 hours to obtain pretreated reed leaves.

[0051] Additive: Mix trimethylhexadecylammonium bromide, sodium tripolyphosphate and sodium citrate at a mass ratio of 8:3:1 to obtain the additive.

[0052] Pretreatment of fly ash: Take fly ash and 15% sodium bicarbonate solution according to the mass ratio of 1:10, mix and stir for 45 minutes, filter, take the filter residue according to the mass ratio of 25:1, add silane coupling agent KH-550 and mix Grind for 3 hours to obtain pretreated fly ash.

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com