Purification method for recycling culture wastewater

A technology for aquaculture wastewater and seawater, applied in chemical instruments and methods, animal husbandry wastewater treatment, water pollutants, etc., can solve the problems of high operating cost, low treatment efficiency, impact, etc., and achieve the effect of simplified operation and convenient magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

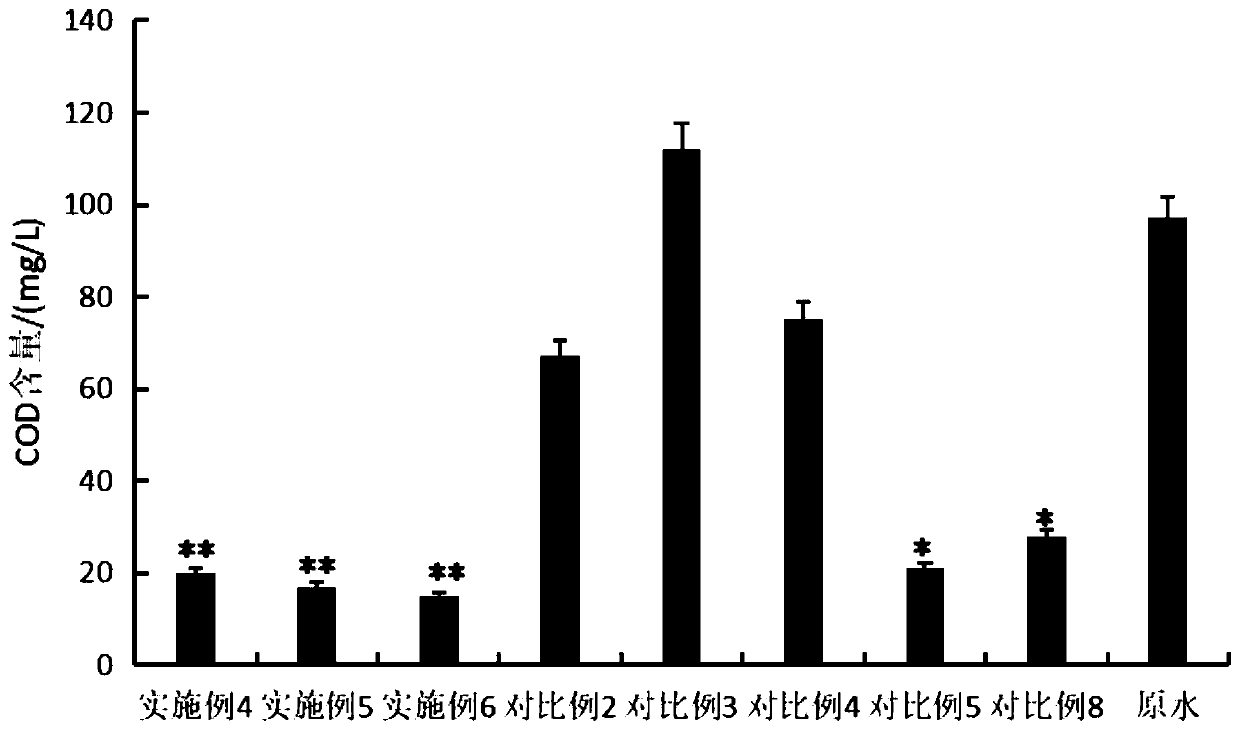

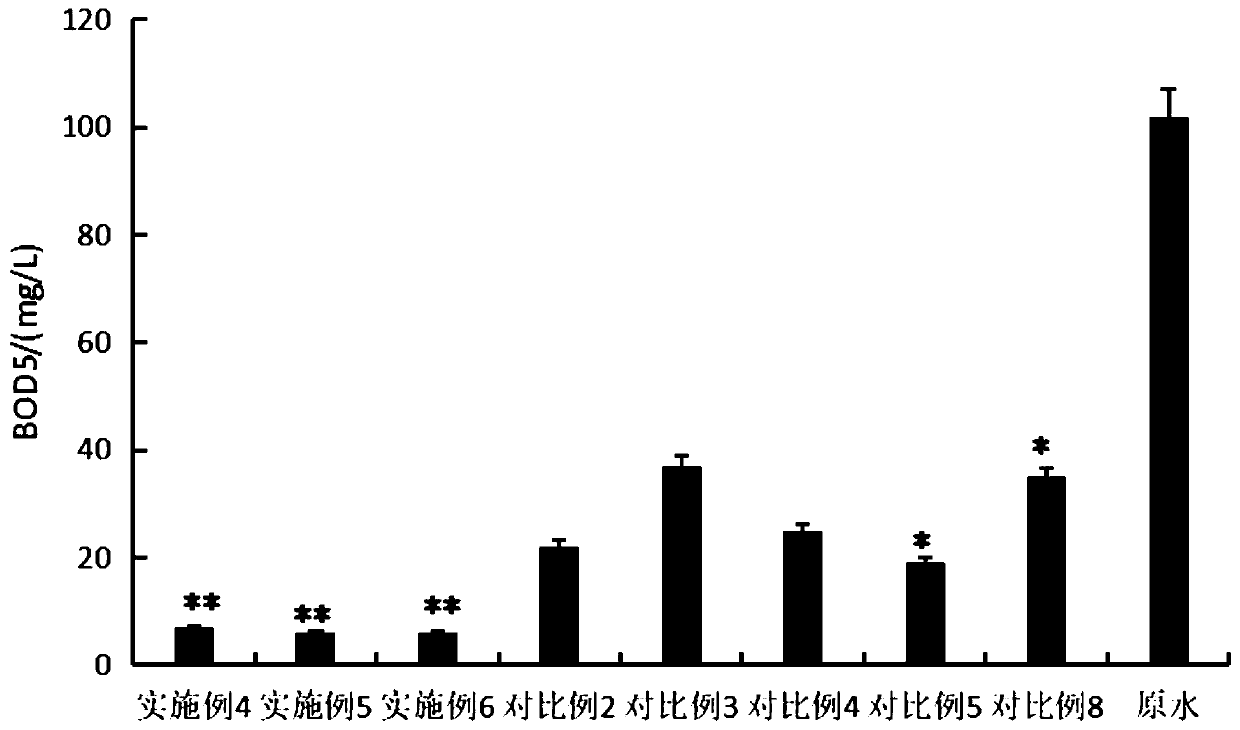

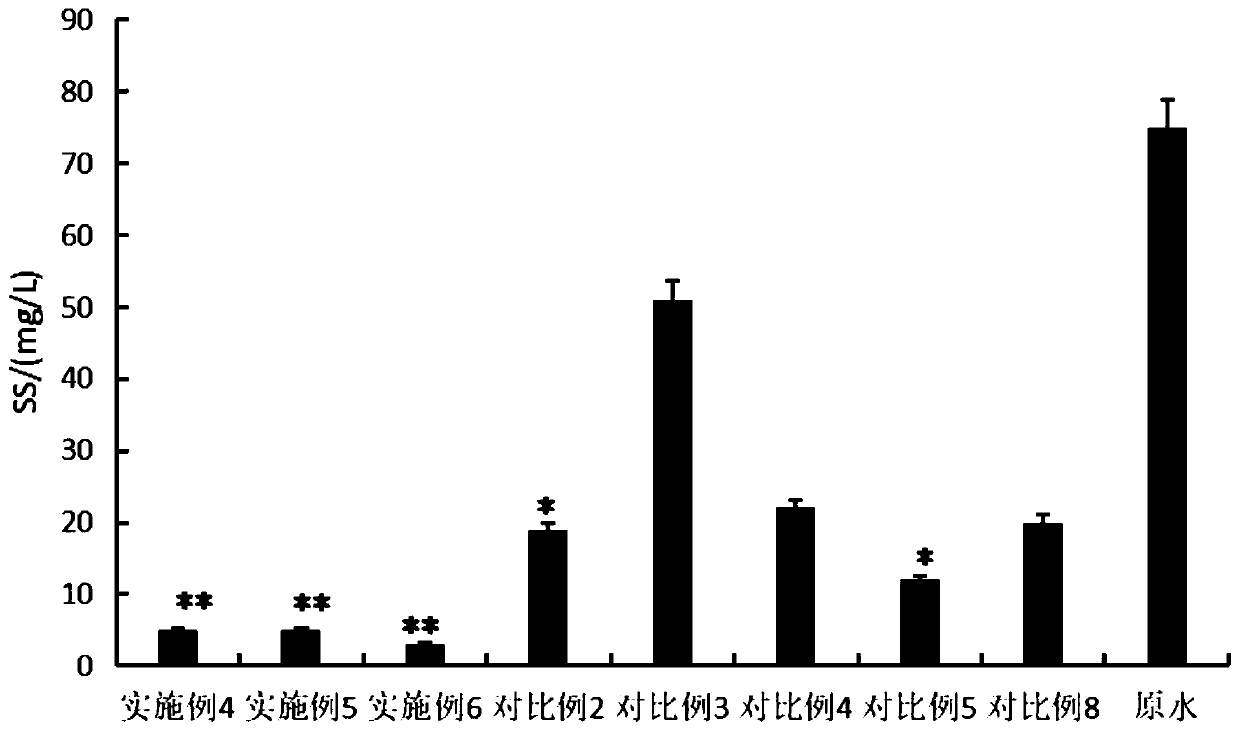

Examples

Embodiment 1

[0038] The preparation method of the magnetic composite flocculant is as follows:

[0039] S1. Preparation of magnetic nanoparticles: 10g of ferric chloride hexahydrate and 20g of ferrous chloride tetrahydrate were heated up to the reaction temperature in a nitrogen atmosphere, and then 100mL of 20wt% ammonia water was added dropwise, and reacted at a constant temperature of 50°C for 2h under the protection of nitrogen. to room temperature, the synthesized magnetic nanoparticles were washed with deionized water several times, separated by a magnet, and magnetic nanoparticles were obtained for use;

[0040] S2. Preparation of magnetic composite flocculant: Add 2g of magnetic nanoparticles and 20mL of 20wt% ammonia water to deionized water, add 0.01g of silane coupling agent dropwise after heating up to the reaction temperature, react at constant temperature under nitrogen protection for 3 hours, add 7g of composite flocculation agent (terpolymer of polyacrylamide, methacrylic a...

Embodiment 2

[0042] The preparation method of the magnetic composite flocculant is as follows:

[0043] S1. Preparation of magnetic nanoparticles: 10g of ferric chloride hexahydrate and 30g of ferrous chloride tetrahydrate were heated up to the reaction temperature in a nitrogen atmosphere, and 300mL of 24wt% ammonia water was added dropwise, and reacted at a constant temperature of 60°C for 5h under the protection of nitrogen. to room temperature, the synthesized magnetic nanoparticles were washed with deionized water several times, separated by a magnet, and magnetic nanoparticles were obtained for use;

[0044]S2. Preparation of magnetic composite flocculant: Add 2g of magnetic nanoparticles and 40mL of 24wt% ammonia water into deionized water, add 0.03g of silane coupling agent dropwise after heating up to the reaction temperature, react at constant temperature under nitrogen protection for 6 hours, add 7g of composite flocculation agent (a copolymer of polyacrylamide and acrylic acid,...

Embodiment 3

[0046] The preparation method of the magnetic composite flocculant is as follows:

[0047] S1. Preparation of magnetic nanoparticles: 10g of ferric chloride hexahydrate and 25g of ferrous chloride tetrahydrate were heated to the reaction temperature in a nitrogen atmosphere, and 200mL of 22wt% ammonia water was added dropwise, and reacted at a constant temperature of 55°C for 3.5h under the protection of nitrogen. Cool down to room temperature, wash the synthesized magnetic nanoparticles with deionized water several times, and separate them with a magnet to obtain magnetic nanoparticles for use;

[0048] S2. Preparation of magnetic composite flocculant: Add 2g of magnetic nanoparticles and 30mL of 22wt% ammonia water into deionized water, add 0.02g of silane coupling agent dropwise after heating up to the reaction temperature, react at constant temperature under nitrogen protection for 4.5h, add 7g of composite Flocculant (composite of polyacrylamide and N,N-dimethylacrylamide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com