Ore concentration technique for laterite nickel ore rich in nickel and/or cobalt

A process and enrichment technology, applied in the direction of nickel compounds, cobalt compounds, chemical instruments and methods, etc., can solve the problems of unfavorable environment, complex composition, low nickel yield, etc., and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] best practice

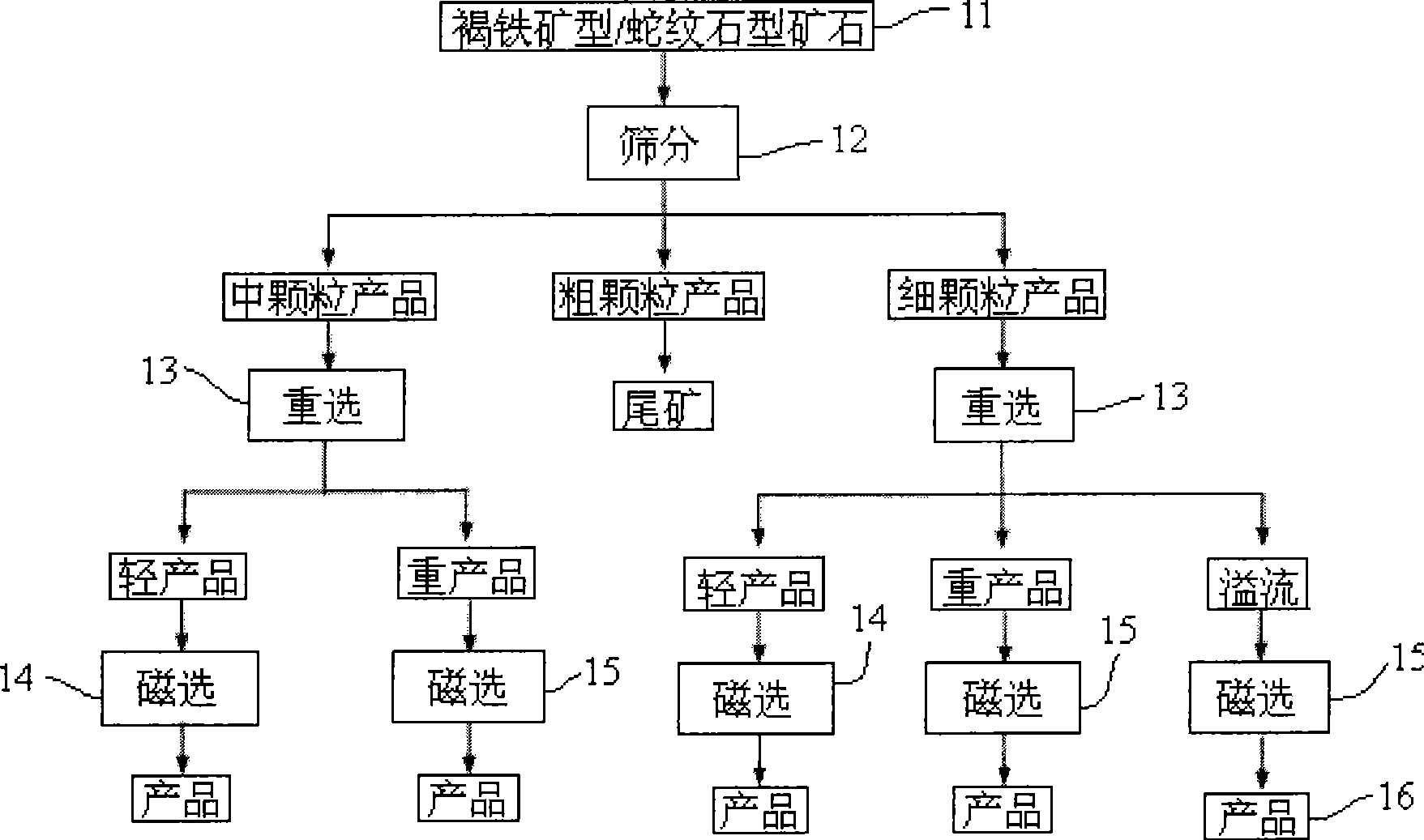

[0027] Such as figure 1 Shown, be that the beneficiation technological process of raw material by limonite type ore comprises the following steps: ore preparation step 11, screening step 12, gravity separation step 13, magnetic separation step 14, magnetic separation step 15, and magnetic separation process step Produced beneficiation products16.

[0028] In an embodiment of the re-selection-magnetic separation combined flow process for producing the target concentrate from limonite-type ore, the following steps are specifically included:

[0029] A. After ore washing, the ore samples are wet-screened with sieves with sieve holes of 1.0mm and 0.076mm, and three grades of products are produced;

[0030] B. Products with a particle size greater than 1mm are not selected, and directly enter the follow-up processing;

[0031] C. After the -1+0.076mm particle size material is sorted by the shaker, the concentrate and tailings directly enter the product,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com