Heat-conducting flame-retardant cigarette paper for cigarettes, and preparation method and application thereof

A cigarette paper and cigarette technology, applied in special paper, paper, papermaking and other directions, can solve the problems of poor thermal conductivity of cigarette paper and tobacco, insufficient smoke generation, and difficulty in fully releasing tobacco flavor components, and achieve the appearance quality and Simultaneous improvement of internal quality, improvement of heat transfer efficiency and flue gas release, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

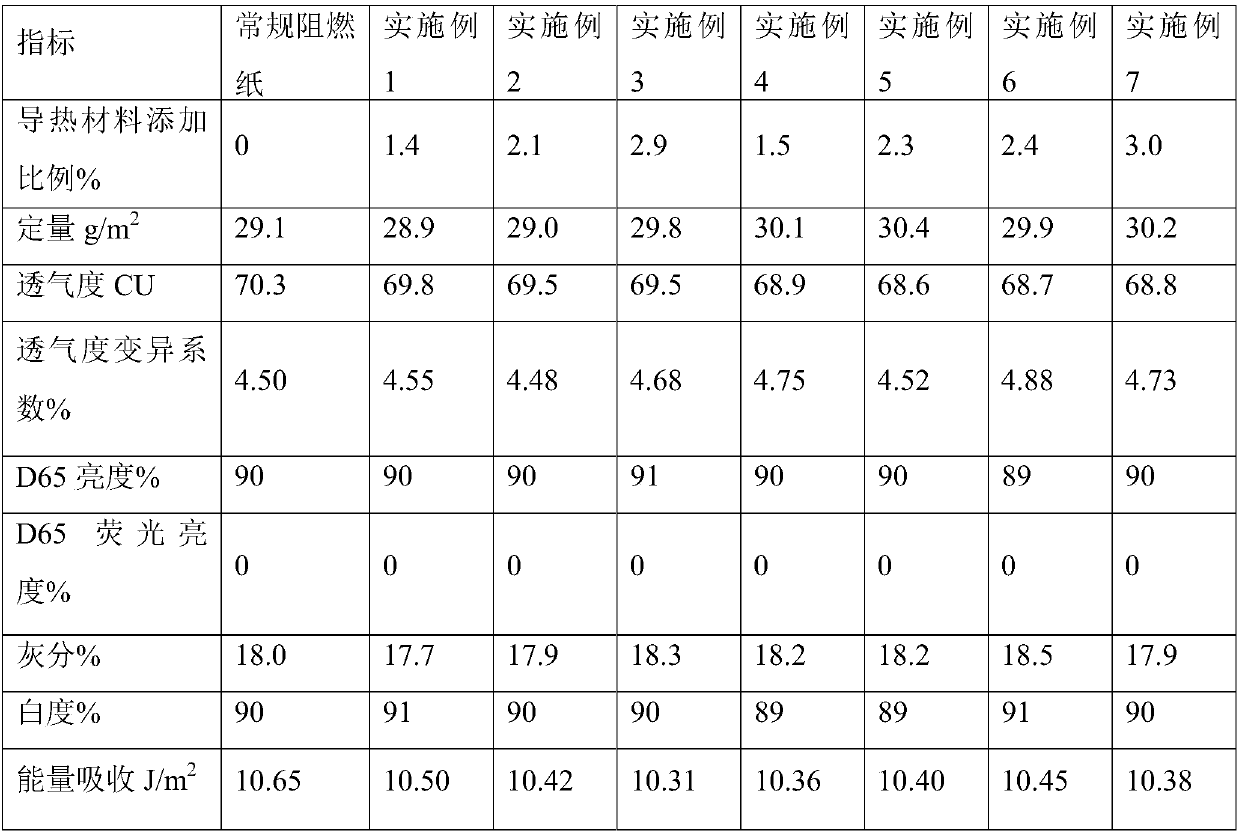

Examples

Embodiment 1

[0042] Get 150 kilograms of coniferous pulp, 450 kilograms of birch broadleaf pulp, add 240 kilograms of filler calcium carbonate. The method of adding heat-conducting materials and flame retardants is: add 100 parts of water, 1 part of quaternary ammonium salt cationic starch, and 0.3 parts of carboxymethyl cellulose in the sizing tank according to the mass fraction, heat up to 90°C for gelatinization, and wait for gelatinization After completion, add 7.5 parts of ammonium polyphosphate, 2.5 parts of ammonium dihydrogen phosphate, 15 parts of aluminum nitride powder, and 1 part of sodium alginate, stir for 25 minutes and mix evenly, and apply it to the cigarette paper through the surface sizing device inside the machine. front and back. Control the characteristics of cigarette paper on the equipment: quantitative 29 g / m 2 .

Embodiment 2

[0044] Get 150 kilograms of coniferous pulp, 450 kilograms of birch broadleaf pulp, add 240 kilograms of filler calcium carbonate. The method of adding heat-conducting materials and flame retardants is as follows: add 100 parts of water, 1.2 parts of quaternary ammonium cationic starch, and 0.3 parts of carboxymethyl cellulose in the sizing tank, heat up to 90°C for gelatinization, and wait for gelatinization After completion, add 7.5 parts of ammonium polyphosphate, 2.5 parts of ammonium dihydrogen phosphate, 20 parts of aluminum nitride powder, and 0.8 parts of sodium alginate, stir for 30 minutes to mix evenly, and apply it to the cigarette paper through the surface sizing device inside the machine. front and back. Control the characteristics of cigarette paper on the equipment: quantitative 29 g / m 2 .

Embodiment 3

[0046] Get 150 kilograms of coniferous pulp, 450 kilograms of birch broadleaf pulp, add 240 kilograms of filler calcium carbonate. The method of adding heat-conducting materials and flame retardants is: add 100 parts of water, 1 part of quaternary ammonium cationic starch, and 0.3 parts of sodium hexametaphosphate in the sizing tank according to the mass fraction, heat up to 90°C for gelatinization, and wait for the gelatinization to complete Then add 7.5 parts of ammonium polyphosphate, 2.5 parts of ammonium dihydrogen phosphate, 30 parts of aluminum nitride powder, and 0.5 parts of sodium alginate, stir for 30 minutes and mix evenly, and apply it to the positive side of the cigarette paper through the machine's inner surface sizing device. negative side. Control the characteristics of cigarette paper on the equipment: quantitative 29 g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com