Electrostatic type fume cleaning equipment with fire-fighting mechanism

A technology of fire protection mechanism and purification equipment, which is applied in the direction of electrostatic separation, external electrostatic separator, emergency control system, etc., can solve the problems of easy combustion, easy spark discharge, equipment damage, etc., and achieve the effect of reducing the temperature of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail by the following examples.

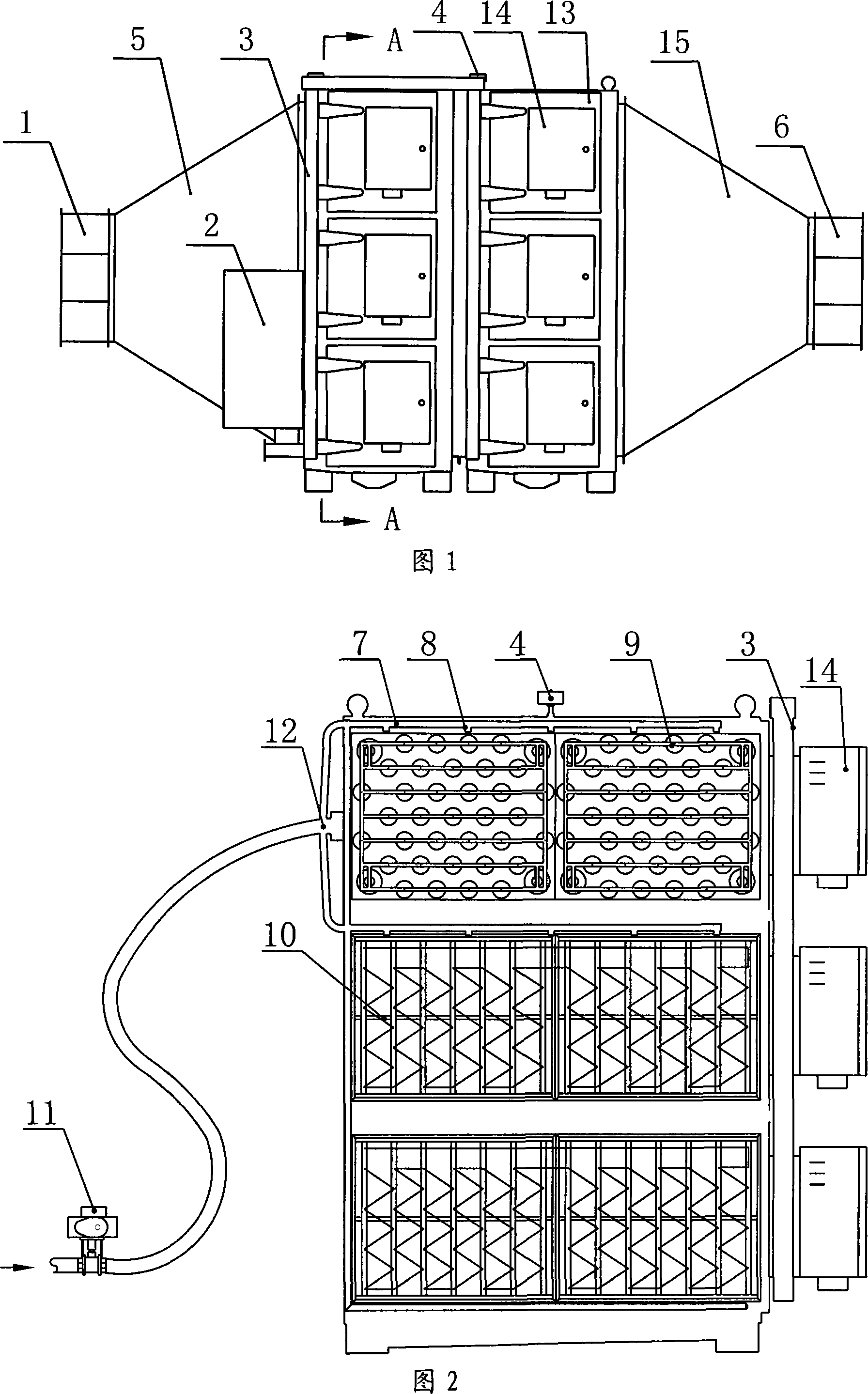

[0015] Referring to Fig. 1 and Fig. 2, a kind of electrostatic smog purification equipment with a fire-fighting mechanism consists of a casing 3, a main control box 2, a DC high-voltage power supply, a front electric box 14, a porous air-uniform partition, and a small inspection door 13 , front-stage fire damper 1, rear-stage fire damper 6, front variable-diameter air duct 5, rear variable-diameter air duct 15, electronically controlled thermometer 4, multiple narrow-pitch honeycomb cylindrical electric fields installed in the casing 3 9, A plurality of temperature sensing nets 10, water supply pipes 7, nozzles 8, electric ball valves 11, and connecting water pipes 12 are formed. The front-stage fire damper 1 is sealed and connected to the front end of the casing 3 through the front variable-diameter air duct 5 , and the rear-stage fire damper 6 is sealed and connected to the rear end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com