Smelting method for stably controlling temperature of heavy rail steel U75V tundish

A smelting method and a stable control technology, applied in the field of metallurgy, can solve problems affecting product quality and enterprise benefits, and achieve the effects of improving product quality stability and pass rate, facilitating production operation, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

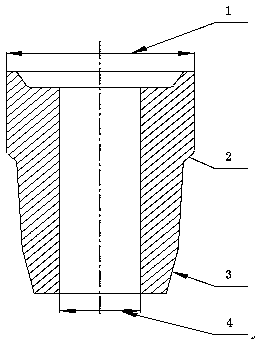

Image

Examples

Embodiment 1

[0025] In this embodiment, the smelting method for stably controlling the temperature of the heavy rail steel U75V tundish includes pre-desulfurization of molten iron, converter smelting, LF refining, RH refining and continuous casting process. The specific process steps are as follows:

[0026](1) Converter smelting: Add desulfurized molten iron into the converter, add active lime, light-burned dolomite, and iron oxide balls for converter smelting; before converter tapping, the ladle lining temperature is 865°C after turnover; Quicksand, low-carbon tapping process, smelting end point C: 0.08%, tapping temperature 1626°C, slag blocking, slag layer thickness 45mm, slag amount 3kg / t steel, 1 / 4 hour tapping Add low-nitrogen carburizer, low-aluminum ferrosilicon, high-carbon ferromanganese, silicon-calcium-barium deoxidation alloying, add slag washing material at a ratio of 4.2kg / t steel after deoxidation alloying, steel tapping time 4min15s, ladle argon blowing time 5min30s, the ...

Embodiment 2

[0034] In this embodiment, the smelting method for stably controlling the temperature of the heavy rail steel U75V tundish includes pre-desulfurization of molten iron, converter smelting, LF refining, RH refining and continuous casting process. The specific process steps are as follows:

[0035] (1) Converter smelting: Add desulfurized molten iron into the converter, add active lime, light-burned dolomite, and iron oxide balls for converter smelting; before converter tapping, the ladle lining temperature is 880°C after turnover; 6 minutes before converter tapping, add lead Quicksand, low-carbon tapping process, smelting end point C: 0.07%, tapping temperature 1635°C; slag blocking, slag layer thickness 40mm, slag amount 4kg / t steel, 1 / 4 tapping Add low-nitrogen recarburizer, low-aluminum ferrosilicon, high-carbon ferromanganese, silicon-calcium-barium deoxidation alloying, after deoxidation alloying, add slag washing material at a ratio of 4.5kg / t steel, and the tapping time is...

Embodiment 3

[0043] In this embodiment, the smelting method for stably controlling the temperature of the heavy rail steel U75V tundish includes pre-desulfurization of molten iron, converter smelting, LF refining, RH refining and continuous casting process. The specific process steps are as follows:

[0044] (1) Converter smelting: add desulfurized molten iron into the converter, add active lime, light-burned dolomite, and iron oxide balls for converter smelting; Quicksand, using low-carbon tapping process, smelting end point C: 0.065%, tapping temperature 1630°C; using slag blocking tapping, controlling the thickness of the slag layer to 35mm, controlling the amount of slag dropped to 4.5kg / t steel, and tapping 1 / 4 Add low-nitrogen recarburizer, low-aluminum ferrosilicon, high-carbon ferromanganese, silicon-calcium-barium deoxidation alloying, and add slag washing material at a ratio of 4.6kg / t steel after deoxidation alloying; tapping time is 4min18s, and the ladle is blown with argon Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com