Preparation method of low-hardness and high-transparency polyether amide permanent antistatic agent

A permanent antistatic, polyetheramide technology, used in the preparation of high transparency polyetheramide permanent antistatic agent, low hardness field, can solve the problem of limited permanent antistatic agent products, product color black and gray, Prepare high transparency and other problems to achieve the effects of high transparency, lasting antistatic properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

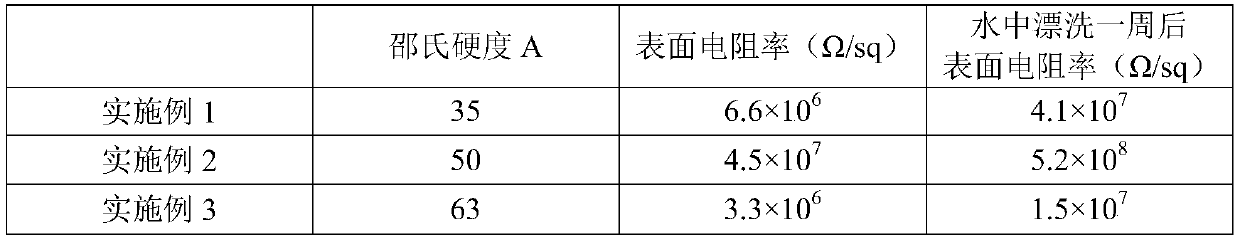

Embodiment 1

[0031] (1) Add 200g of polyamide 1010 salt into the reaction kettle, then add 80g of adipic acid, replace the air in the kettle with nitrogen, raise the temperature to 210°C, keep the pressure for 2 hours after the pressure reaches 2.0MPa, and then release the pressure to normal pressure , and then heated up to 240°C for 1.5h to obtain a polyamide 1010 prepolymer;

[0032] Using the polyamide prepolymer obtained above, add 800g of polyethylene glycol, 40g of trimethylolpropane, 10g of antioxidant 1010 and 5g of tetrabutyl titanate, mix well and add to the reaction kettle, and replace with nitrogen The air in the kettle is first heated to 230°C for 2 hours, then heated to 260°C and vacuumed, and then reacted for 3 hours at a pressure of 2KPa, filled with nitrogen and discharged, drawn and pelletized to obtain a polyetheramide elastomer .

[0033] (2) Utilize the above-mentioned obtained polyether amide elastomer, add 50g lithium perchlorate, 120g sodium dodecylsulfonate, 15g w...

Embodiment 2

[0035] (1) Add 300g of polyamide 1012 salt into the reaction kettle, then add 90g of sebacic acid, replace the air in the kettle with nitrogen, raise the temperature to 210°C, keep the pressure for 2h after the pressure reaches 2.0MPa, and then release the pressure to normal pressure , and then heated to 240 ° C for 2 hours to obtain polyamide 1012 prepolymer;

[0036]Using the polyamide prepolymer obtained above, add 400g polyethylene glycol and 300g amino-terminated polyoxyethylene ether, 40g trimethylolpropane, 12g antioxidant 1010 and 6g tetrabutyl titanate, and mix well Put it into the reaction kettle, replace the air in the kettle with nitrogen, first raise the temperature to 230°C for 2 hours, then raise the temperature to 250°C and vacuumize it, and react for 3 hours at a pressure of 1KPa, then fill it with nitrogen and discharge the material, pull the rod, Pelletize to obtain polyetheramide elastomer.

[0037] (2) Utilize the polyether amide elastomer obtained above,...

Embodiment 3

[0039] (1) Add 400g of polyamide 1212 salt into the reaction kettle, then add 80g of dodecanedibasic acid, replace the air in the kettle with nitrogen, raise the temperature to 200°C, keep the pressure for 2h after the pressure reaches 1.8MPa, and then release the pressure Return to normal pressure, then raise the temperature to 230°C for 2 hours to obtain polyamide 1212 prepolymer;

[0040] Using the polyamide prepolymer obtained above, add 600g of polytetrahydrofuran ether glycol, 30g of trimethylolpropane, 10g of antioxidant 1098 and 6g of tetrabutyl titanate, mix them uniformly and add them to the reaction kettle, and pass nitrogen gas Replace the air in the kettle, first raise the temperature to 220°C to react for 2 hours, then raise the temperature to 250°C and evacuate, and react at a pressure of 2KPa for 3 hours, fill with nitrogen and discharge, draw strands, and cut into pellets to obtain polyetheramide elasticity body.

[0041] (2) Utilize the polyether amide elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com