Method for preparing high-toughness cottonseed protein based composite membrane

A technology of cottonseed protein and composite membrane, which is applied in the field of protein-based membrane materials, can solve the problems of reducing tensile strength and elongation at break, and achieve the effect of enhancing tensile strength, enhancing elongation at break, and broadening applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

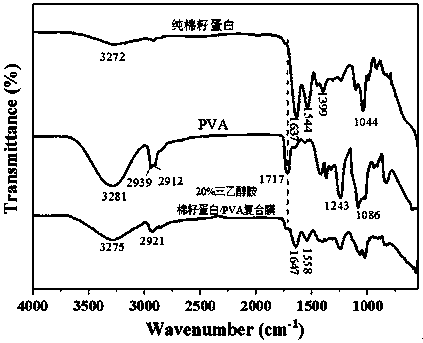

[0031] The invention provides a method for preparing a high-toughness cottonseed protein-based composite film comprising the following steps:

[0032] (1) Extraction of refined cottonseed protein:

[0033] S1: Mix and stir the cottonseed meal and the newly prepared alkaline solution according to the mass ratio of 1:10 to 1:15, and obtain the crude cottonseed protein extract after centrifugation and filtration;

[0034] S2: put the crude cottonseed protein extract into a dialysis bag, and dialyze in deionized water at 4-25°C for 5-7 days;

[0035] S3: Collect the cottonseed protein solution after dialysis, and adjust the pH to 4.5-5.5 with dilute hydrochloric acid, and a large amount of protein precipitation can be seen;

[0036] S4: Centrifuge, separate and dry the obtained protein precipitate to obtain pure cottonseed protein;

[0037] (2) Preparation of cottonseed protein solution: mixing cottonseed protein with a mass ratio of 1:5 to 1:30 and an inorganic alkali solution ...

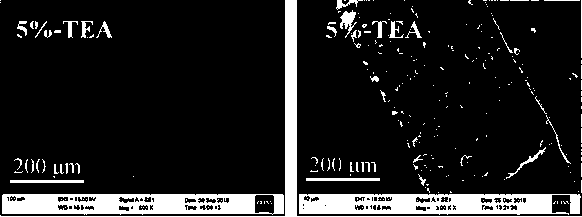

Embodiment 1

[0053] Dissolve 0.60g cottonseed protein in 9.4g sodium hydroxide solution (pH=10) to prepare 10g 6wt% cottonseed protein solution. 1.5g of PVA was dissolved in 23.5g of deionized water to prepare 25g of 6wt% PVA solution. According to the cottonseed protein:PVA mass ratio of 3:7, 9g of cottonseed protein solution was added to 21g of PVA solution, and stirred in a constant temperature water bath at 50°C for 1 hour to obtain solution A. Accurately drop 0.090 g of pure triethanolamine solution into solution A, and stir in a constant temperature water bath at 50° C. for 1.5 hours to obtain solution B. After the solution B was cooled to room temperature, it was poured into a polypropylene mold, and placed horizontally in a constant temperature and humidity box at 25°C and 50%RH to dry for 12 hours.

Embodiment 2

[0055] Dissolve 0.60g cottonseed protein in 9.4g sodium hydroxide solution (pH=10) to prepare 10g 6wt% cottonseed protein solution. 1.5g of PVA was dissolved in 23.5g of deionized water to prepare 25g of 6wt% PVA solution. According to the cottonseed protein:PVA mass ratio of 3:7, 9g of cottonseed protein solution was added to 21g of PVA solution, and stirred in a constant temperature water bath at 50°C for 1 hour to obtain solution A. Accurately drop 0.180 g of pure triethanolamine solution into solution A, and stir in a constant temperature water bath at 50° C. for 1.5 hours to obtain solution B. After the solution B was cooled to room temperature, it was poured into a polypropylene mold, and placed horizontally in a constant temperature and humidity chamber at 25°C and 50% RH to dry for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com