Method for producing xylooligosaccharide under catalysis of xylonic acid

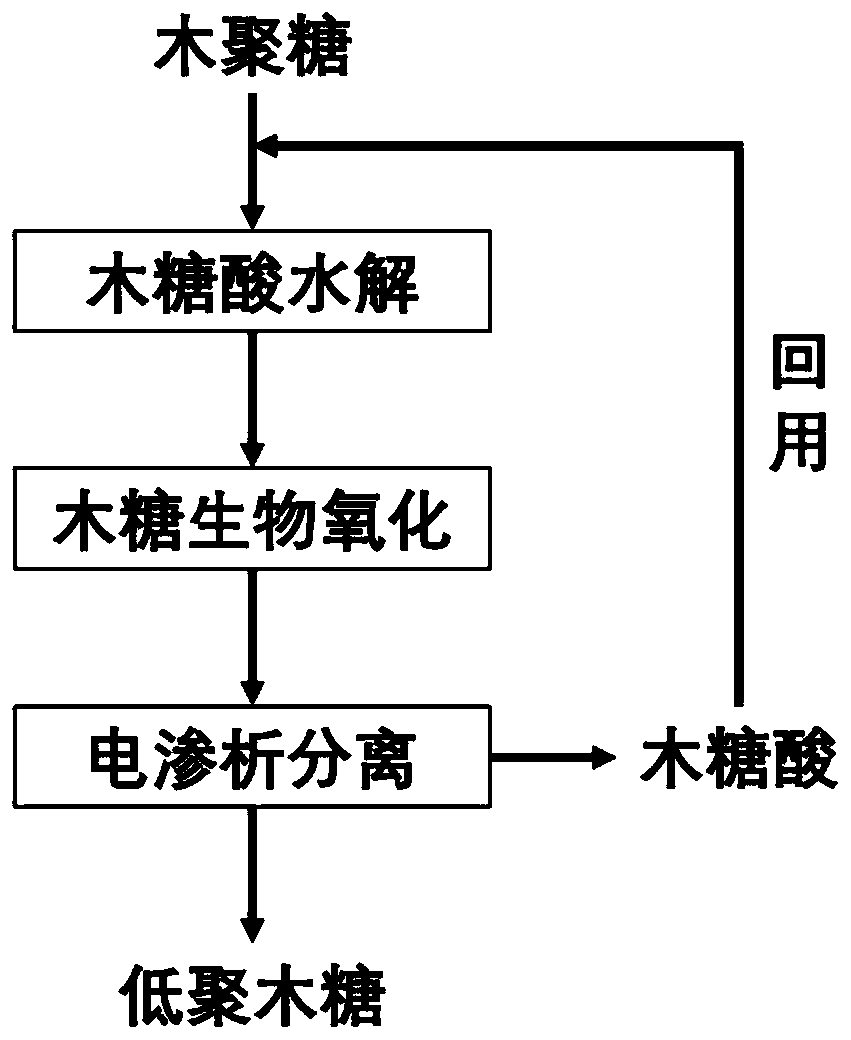

A technology of xylo-oligosaccharides and xylosaccharides, which is applied in the fields of food engineering and chemical engineering, can solve the problems of high cost of biological enzymes, many by-products, and low yield of xylo-oligosaccharides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

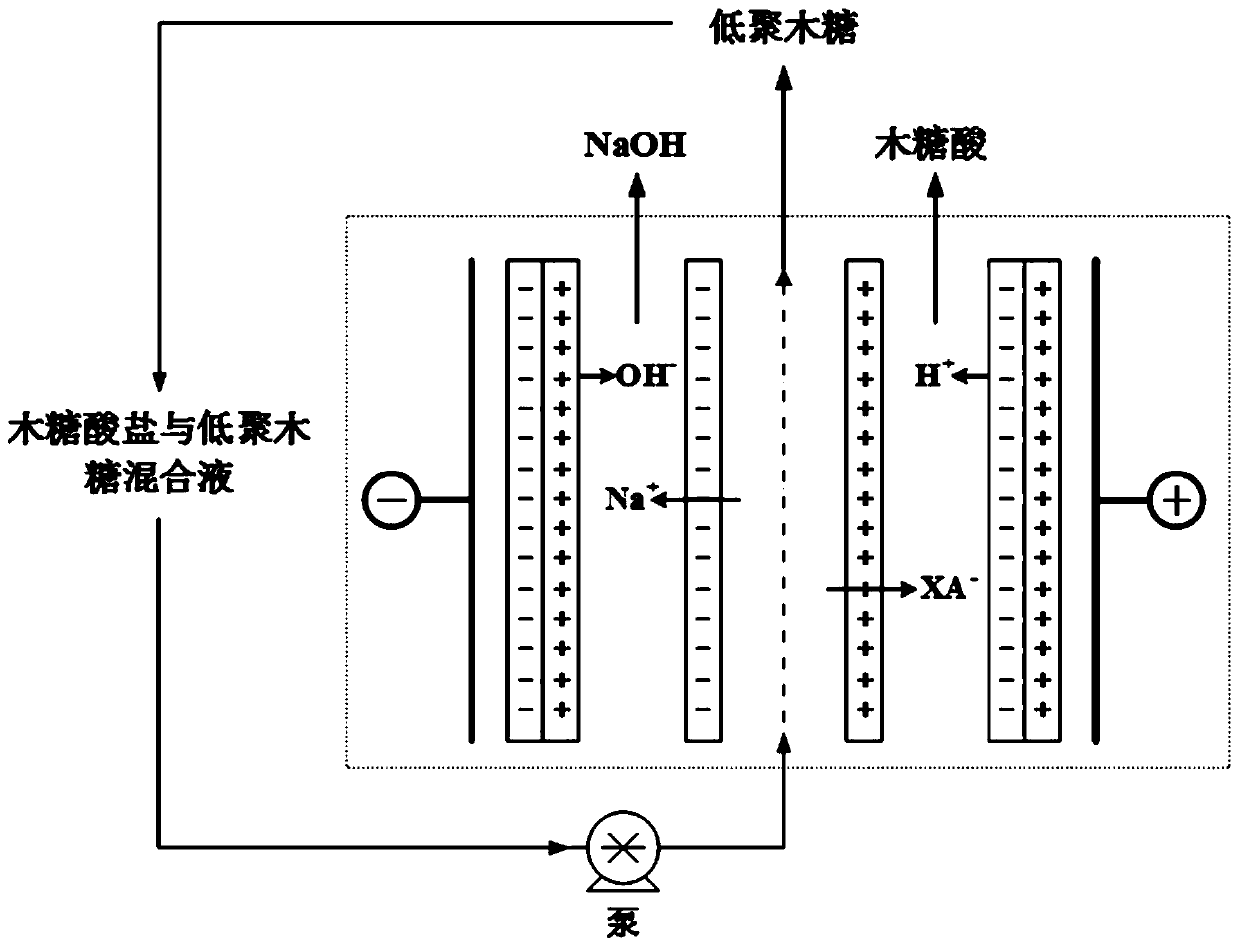

Method used

Image

Examples

Embodiment 1

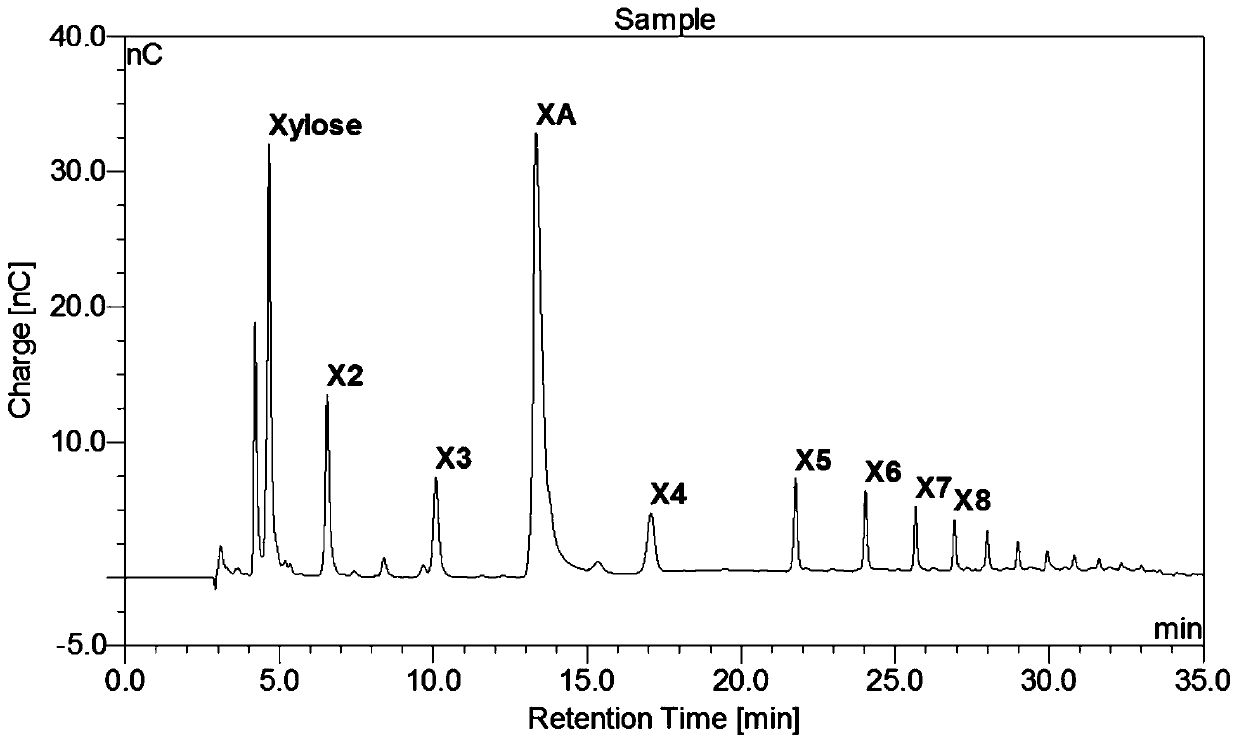

[0026] In a 1L mechanically stirred stainless steel high-pressure reaction tank, add 50g of corncob alkali-extracted xylan and 500mL of 5% (mass fraction) xylose acid solution, seal it, start stirring (50rpm), and heat to 150°C for 75min After the reaction, the reactant tank is down to room temperature, and the reacted solid-liquid mixture is packed into a vacuum pulp washer, and is separated from unhydrolyzed solids and xylan hydrolyzate by extrusion and filtration (hydrolyzate mainly It is a mixture of xylose, xylonic acid and xylooligosaccharide). The obtained xylan hydrolyzate sample was analyzed for its sugar components by high-efficiency anion-exchange chromatography, chromatographic conditions: American Thermo Fisher ICS5000 ion chromatography, equipped with CarboPacTM PA200 (3mm × 250mm) chromatographic column, PAD integral amperometric detector, column The temperature was 30°C, the injection volume was 10 μL; binary gradient elution was performed with 100 mmol / L sodiu...

Embodiment 2

[0031] In a 1L mechanically stirred stainless steel high-pressure reaction tank, add 50g of corncob alkali-extracted xylan and 500mL of 10% (mass fraction) xylose acid solution, seal it, start stirring (50rpm), and heat to 160°C for 45min After the reaction, the reactant tank is down to room temperature, and the reacted solid-liquid mixture is packed into a vacuum pulp washer, and is separated from unhydrolyzed solids and xylan hydrolyzate by extrusion and filtration (hydrolyzate mainly It is a mixture of xylose, xylonic acid and xylooligosaccharide). The obtained xylan hydrolyzate sample was analyzed for its sugar components by high-efficiency anion-exchange chromatography, chromatographic conditions: American Thermo Fisher ICS5000 ion chromatography, equipped with CarboPacTM PA200 (3mm × 250mm) chromatographic column, PAD integral amperometric detector, column The temperature was 30°C, the injection volume was 10 μL; binary gradient elution was performed with 100 mmol / L sodi...

Embodiment 3

[0033]In a 1L mechanically stirred stainless steel high-pressure reaction tank, add 50g of corncobs and 500mL of 5% (mass fraction) xylose acid solution, seal and start stirring (50rpm), and heat to 170°C for 15min; after the reaction, wait for the reaction After the body tank is lowered to room temperature, put the reacted solid-liquid mixture into a vacuum pulp washer, squeeze and filter to separate the unhydrolyzed solids and xylan hydrolyzate (the hydrolyzate is mainly xylose, xylose acid and xylooligosaccharide mixture). The obtained xylan hydrolyzate sample was analyzed for its sugar components by high-efficiency anion-exchange chromatography, chromatographic conditions: American Thermo Fisher ICS5000 ion chromatography, equipped with CarboPacTM PA200 (3mm × 250mm) chromatographic column, PAD integral amperometric detector, column The temperature was 30°C, the injection volume was 10 μL; binary gradient elution was performed with 100 mmol / L sodium hydroxide and 500 mmol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com