Post-treatment method for regulating and controlling two-dimensional perovskite crystallization process by utilizing ethanol

A technology of perovskite and ethanol, applied in the field of materials, to achieve the effects of mild conditions, improved fluorescence lifetime, and improved fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

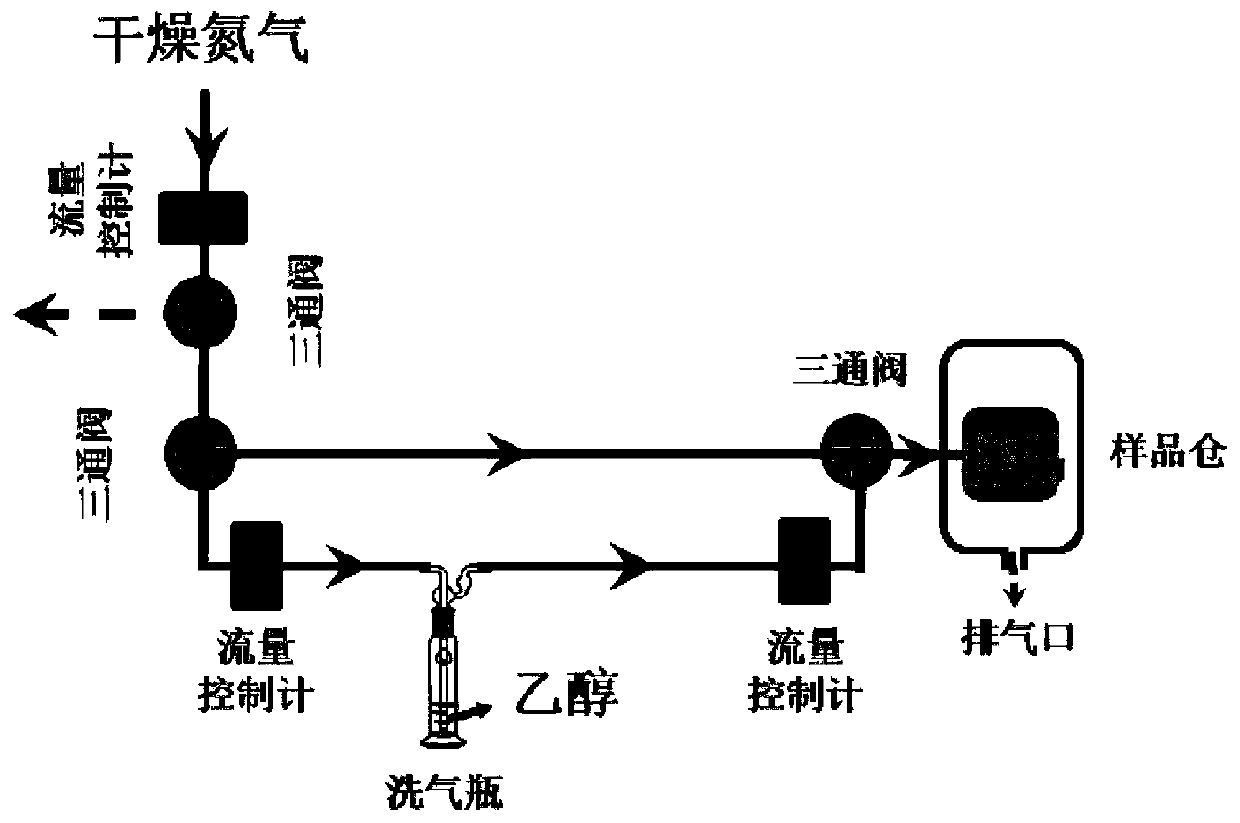

[0040] A kind of ethanol post-treatment of the present invention regulates two-dimensional perovskite (OA) 2 (MA)Pb 2 I 7 A method for a crystallization process, comprising the steps of:

[0041] Step 1, will utilize the (OA) prepared by spin-coating method 2 (MA)Pb 2 I 7 The crystal film is placed in the sample chamber;

[0042] Step 2, dry N with a flow rate of 3L / min 2 (moisture content less than 20%) into the sample chamber, duration 3min;

[0043] Step 3, dry N with a flow rate of 3L / min 2 (water content less than 20%) The method of passing 50mL of ethanol liquid blows ethanol vapor into the sample chamber for 3 minutes;

[0044] Step 4, cut off the ethanol supply, dry N with a flow rate of 3L / min 2 (moisture content less than 20%) into the sample chamber, duration 3min;

[0045] Step 5. Repeat steps (3) to (4), and alternately pass 3min dry N 2 and ethanol vapor, a total of 3 times.

Embodiment 2

[0047] To (OA) of Example 1 2 (MA)Pb 2 I 7 The crystal thin film is characterized and analyzed, and the specific steps include:

[0048] (1) Changes in fluorescence intensity

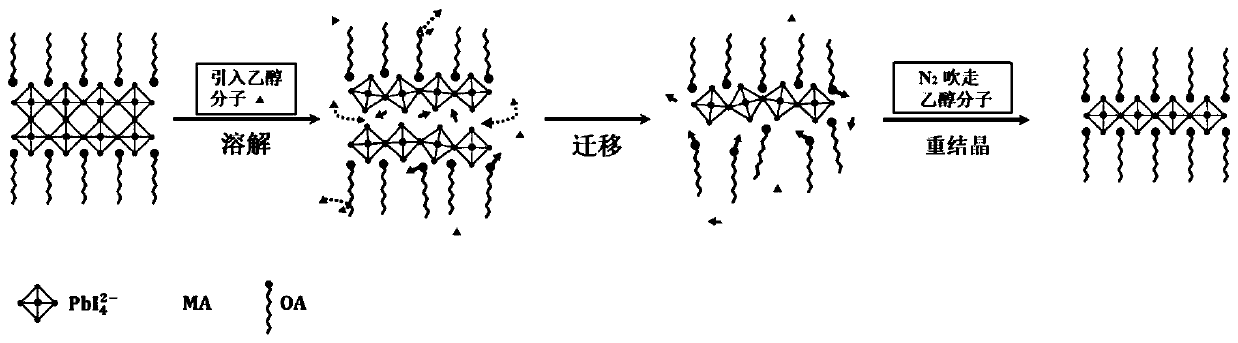

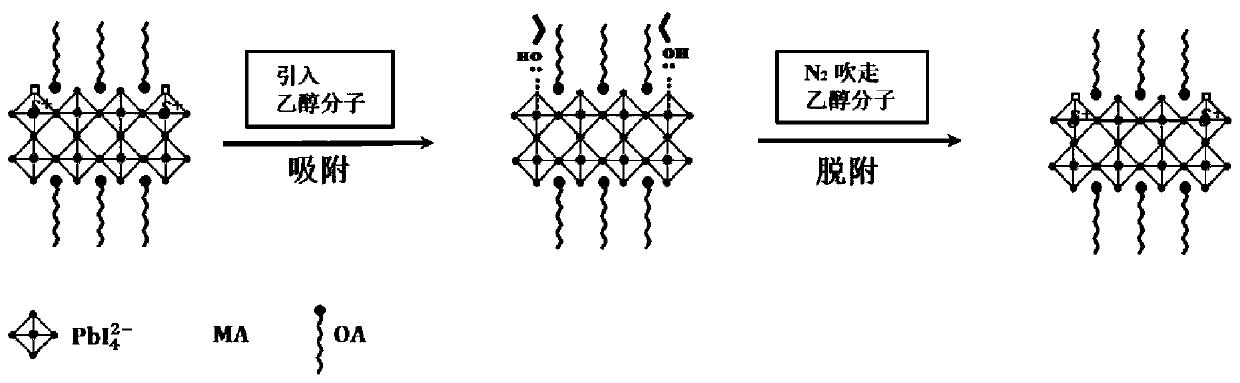

[0049] (OA) 2 (MA)Pb 2 I 7 The fluorescence intensity of the crystal film was recorded in real time by a self-built wide-field fluorescence microscope. A 450nm semiconductor laser was used as an excitation source, a 40x objective lens (Olympus LUCPlanFI, NA=0.6) was used, and an electron multiplier charge coupler (Andor, iXon Ultra 888) was used as a detector. The exposure time is 100ms, and the video of the fluorescence intensity change is collected in real time. The results are as follows: Figure 4 as shown in a. From Figure 4 It can be seen in a that after introducing ethanol at 3min, (OA) 2 PB 4 (n=1) crystals appeared; and only with ethanol vapor passed, (OA) 2 PB 4 The fluorescence intensity of the crystal will only increase. It is worth noting that, in the ethanol / N 2 Ambience sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com