Cryogenic laser shot blasting device and processing method

A laser peening and cryogenic technology, applied in manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve problems such as insufficient clamping force, weakening strengthening effect, affecting light transmittance, etc., to avoid insufficient clamping force, Improve laser light transmittance and avoid glass breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

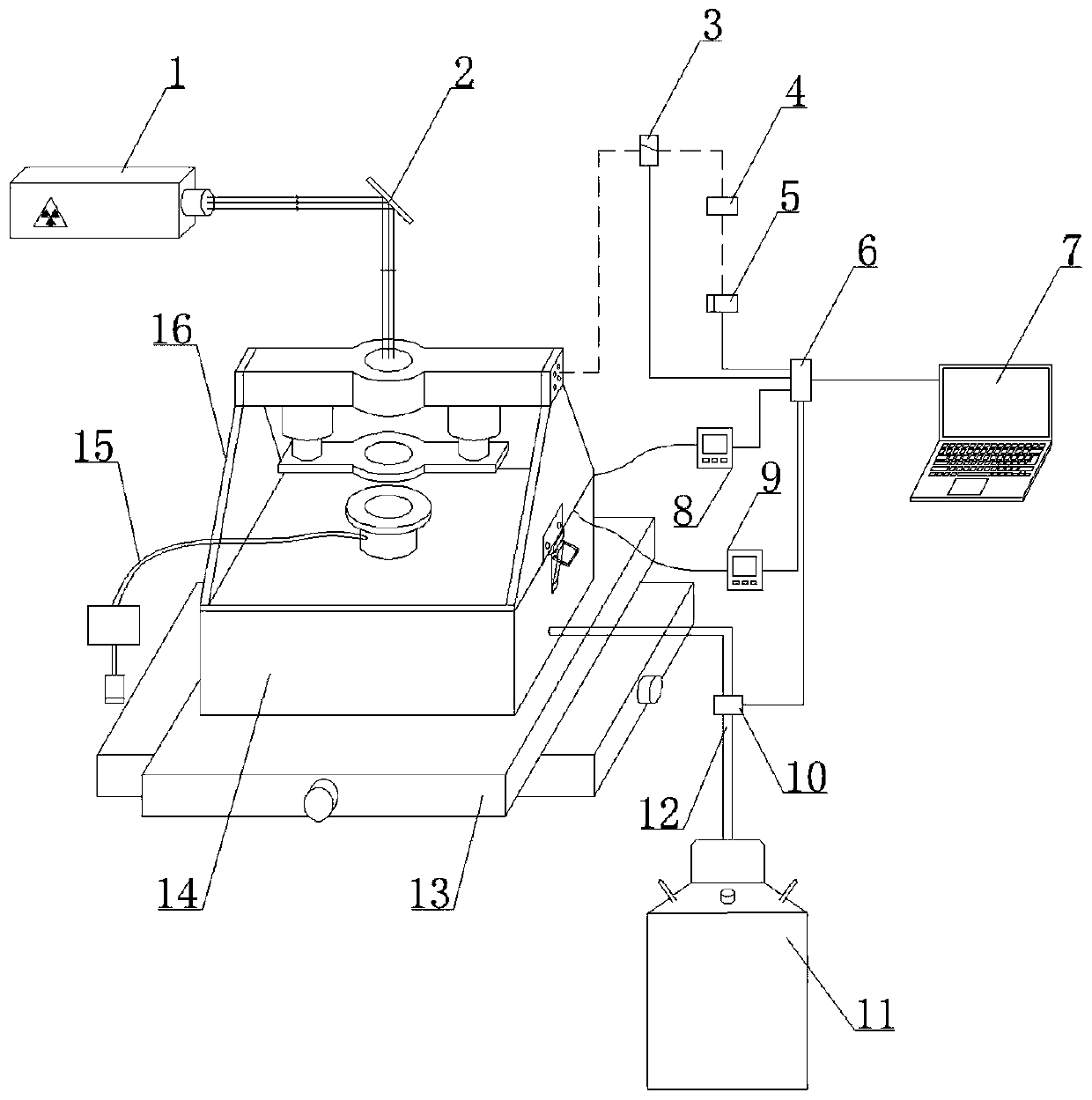

[0032] Such as figure 1 As shown, the cryogenic laser peening device of the present invention comprises laser 1, computer 7, workbench 13, low temperature control device 14, drying device 15, PLC6 and pressure control device 16, and described low temperature control device 14 is fixed on the working On the platform 13, the worktable 13 can move in a plane; the pressure control device 16 cooperates with the low temperature control device 14 and is fixed through a lock connection.

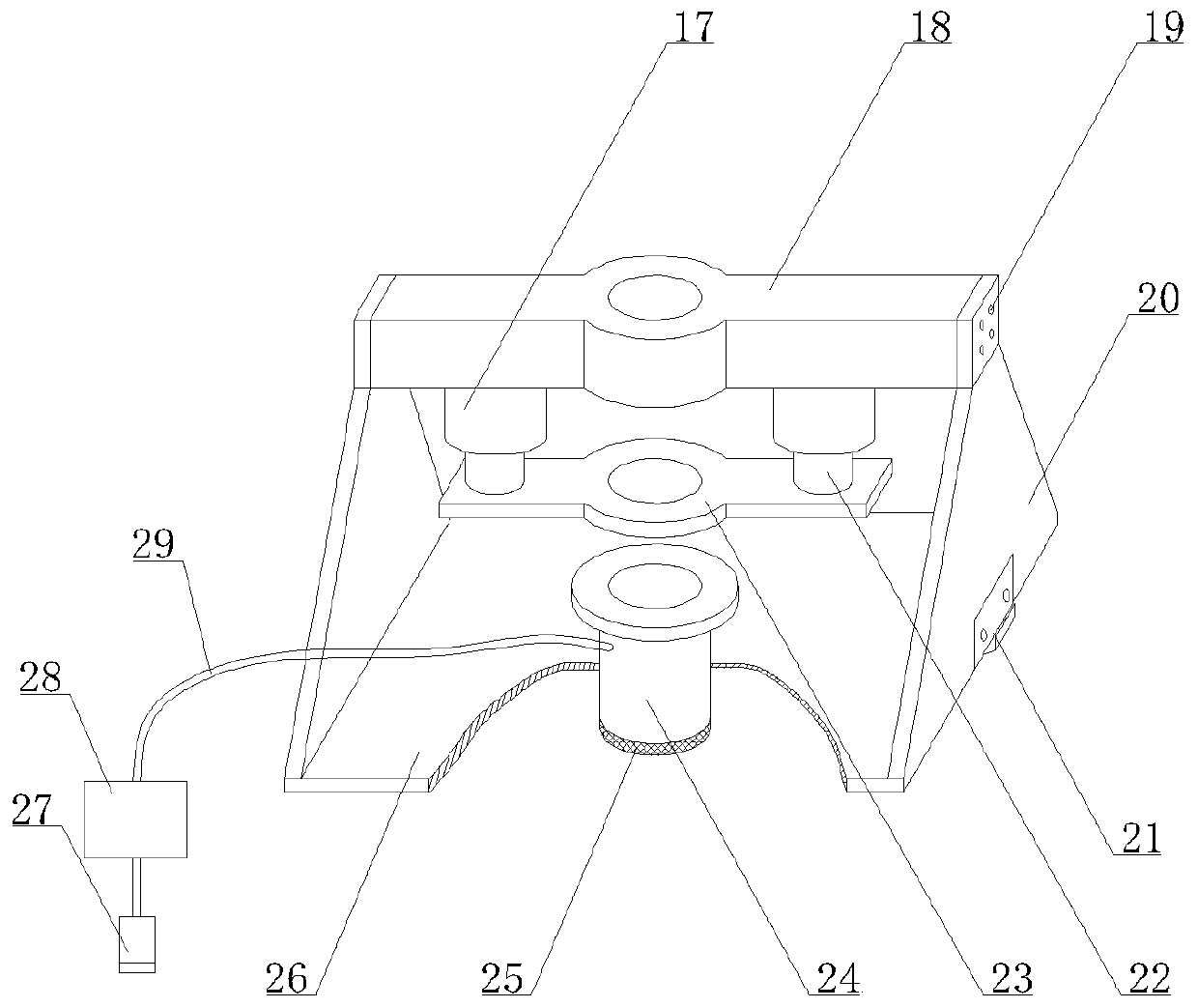

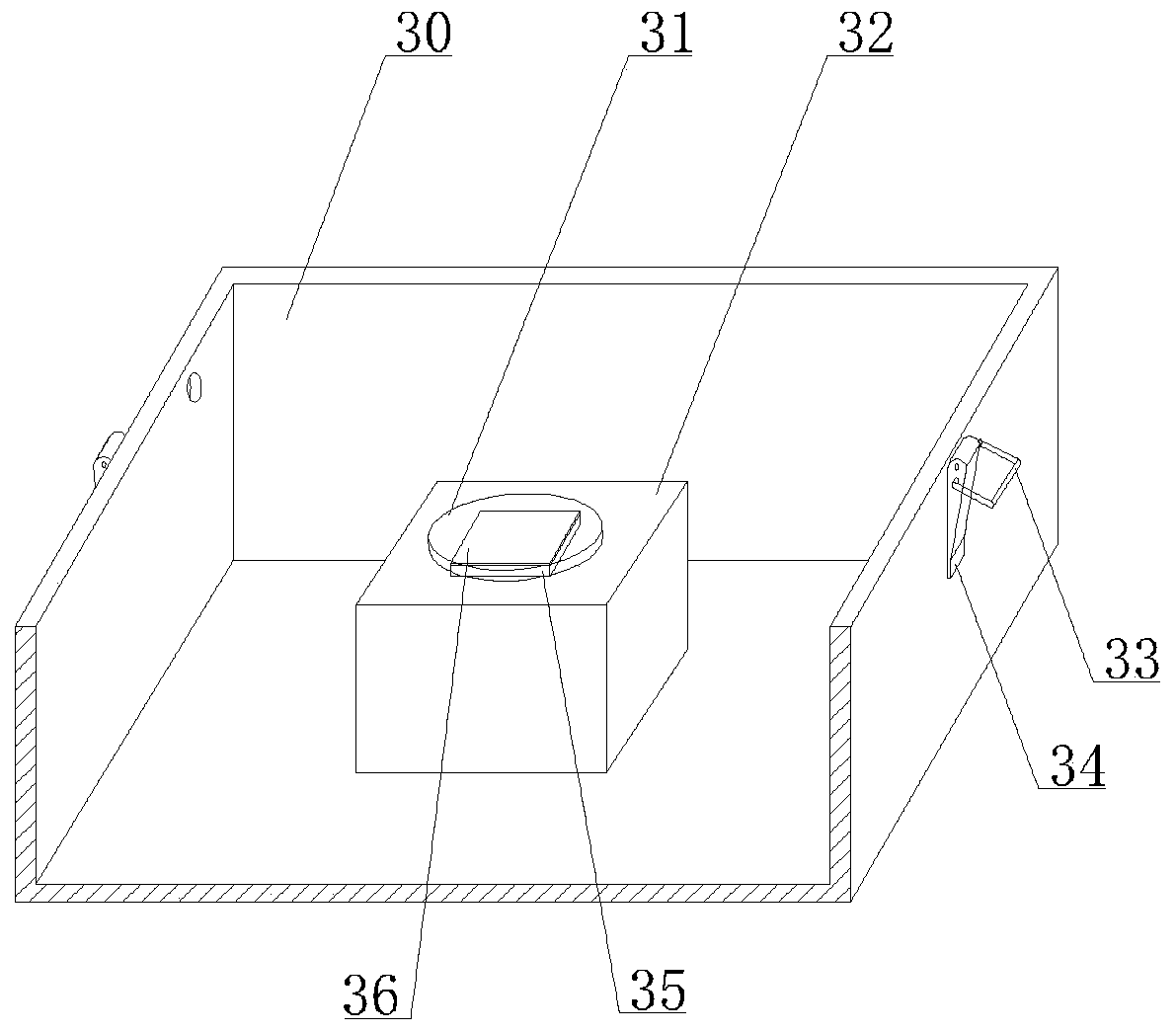

[0033] Such as figure 2 and image 3 As shown, the low temperature control device 14 includes a cryogenic box 30, a flow control valve 10, a liquid nitrogen tank 11, a liquid nitrogen delivery pipe 12 and an ultra-low temperature sensor 9, and the cryogenic box 30 is fixed on the workbench 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com