Manufacturing method of digital PEAK substrate restoration and bonding method of digital PEAK substrate restoration with tooth body

A manufacturing method and restoration technology, applied in the field of oral restoration, can solve problems such as abrasion of opposing natural teeth, excessive weight of restorations, and impact on clinical effects, and achieve increased micromechanical locking force, excellent biocompatibility, and guaranteed The effect of the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for manufacturing a digital PEAK base material restoration, including the following steps:

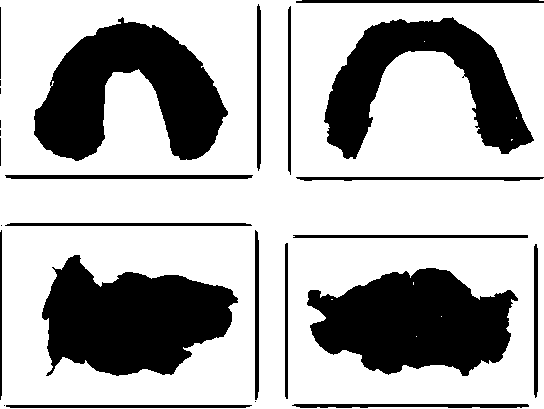

[0040] S1: Scan the patient's mouth with a scanner model 3shapeD2000, obtain the digital model of the patient's maxilla and mandible, and obtain the occlusal relationship. For the obtained digital model, see figure 1 ;

[0041] S2: Based on the obtained digital model and combined with 3 Shape Dental Manager Client design software, a digital restoration model is designed, and the digital restoration model is trimmed and undercut designed. After the design is completed, the occlusal condition is checked, and then the restoration is designed. The bonding surface used for bonding with the tooth is designed to improve the specific surface area and surface roughness of the micro-texture to form a roughened surface, wherein the micro-texture includes a number of bumps and grooves arranged on the bonding surface. or bumps and grooves, which can be of r...

Embodiment 2

[0052] This embodiment provides a method for manufacturing a digital PEAK-based restoration, which is different from Embodiment 1 in that: when designing the numerical model of the restoration, micro-textures are also designed on the outer surface of the restoration, and then After the restoration is printed out by 3D printing, the outer surface of the restoration is subjected to polymerized porcelain baking so that the restoration can be used as an inner crown. 3D printing the micro-texture on the bonding surface of the inner crown and the tooth can improve the bonding performance of the inner crown and the tooth, and the micro-texture on the outer surface of the inner crown can improve the connection stability of the polymer porcelain.

Embodiment 3

[0054] This embodiment provides a method for manufacturing a digital PEAK base material restoration, including the following steps:

[0055] S1: Scan the patient's mouth with a scanner model 3shapeD2000, obtain the digital model of the patient's maxilla and mandible, and obtain the occlusal relationship. For the obtained digital model, see figure 1 ;

[0056] S2: Based on the obtained digital model, combined with 3 Shape Dental Manager Client design software to design a digital restoration model, trim the digital restoration model, fill in the undercut design, check the occlusion after the design is completed,

[0057] S3: Prepare a prosthetic material, which contains 5-20% of titanium dioxide by volume, 1-10% of iron oxide by volume, and the rest is PEEK material. After preparation, a base material is formed, and then it is cut by Wieland si cutting equipment Substrate, to make a restoration, see figure 2 ;

[0058] S4: Cut the bonding surface of the restoration for bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com