Tea oil with strong flavor and preparation method thereof

A tea oil and strong aroma technology, which is applied in the direction of fat oil/fat refining, fat oil/fat production, recovery of fat oil/fatty acid from waste, etc. Promotes bone growth and brain development, improves memory, and prevents aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

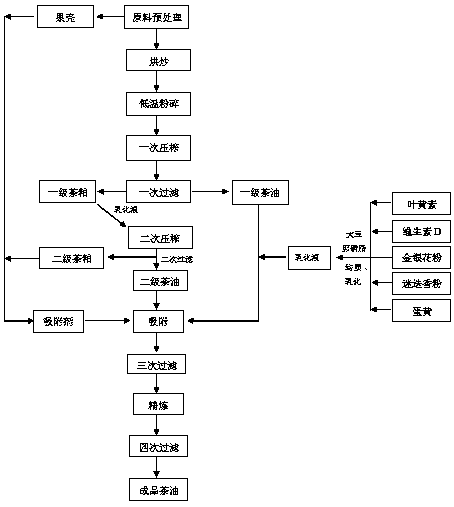

Method used

Image

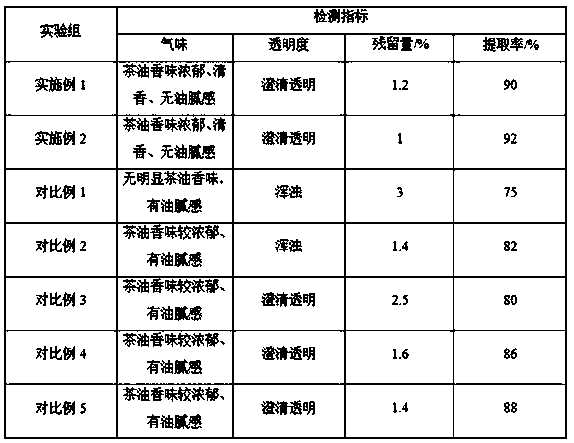

Examples

Embodiment 1

[0030] A preparation method of camellia oil with strong and fragrant flavor, comprising the following steps:

[0031] 1) Raw material pretreatment: select fresh tea fruits that are bright in color, red or yellow, and shiny, remove small, immature and moldy tea fruits, dry the selected tea fruits and shell them to obtain tea seed kernels;

[0032] 2) Roasting: the temperature of the roasting is 100-110°C, and the roasting time is 30-60 minutes. During the roasting process, the tea seeds are constantly stirred; and then crushed at low temperature. The specific operation of the low-temperature crushing is as follows: The tea seed kernels obtained after the roasting treatment are frozen at -5°C-2°C and then crushed to 20-30 mesh;

[0033] 3) One-time pressing: the tea seed kernel obtained in step 2) is pressed once in a press;

[0034] 4) Primary filtration: after filtering the camellia oil obtained after the primary pressing in step 3), to obtain first-grade tea meal and first-g...

Embodiment 2

[0043] The difference between this example and Example 1 is that in step 5), an emulsion is added to the primary tea meal to form a tea meal mixture, wherein the emulsion accounts for 10% of the total mass of the tea meal mixture; in step 7), the adsorbent The quality of the tea oil is 5% of the third grade tea oil; the mass ratio of the mixed quality of the first grade camellia oil and the second grade camellia oil to the added emulsion in step 6) is 20:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com