A kind of preparation method of elastic pressure-sensitive adhesive tape and elastic pressure-sensitive adhesive tape

A technology of pressure-sensitive adhesive tape and pressure-sensitive adhesive layer, which is applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc., and can solve problems such as device damage, complicated manufacturing process, and difficult ultra-thin space. Achieve the effects of avoiding damage to the bonding device, simple preparation process, and good compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the elastic pressure-sensitive adhesive tape provided by the present invention includes:

[0037] Step (1) The glue is coated on the first substrate, and cured in a UV curing oven for 10-30 seconds, so that the glue is initially cured; the composition of the glue includes 1-20 parts by mass of microcapsule powder, 100- 200 parts of polyacrylate resin containing carbon-carbon double bonds, 20-50 parts of diluted monomer containing carbon-carbon double bonds, 1-10 parts of photoinitiator, 1-3 parts of inhibitor, 30-50 parts of liquid tackifying resin , 0-70 parts color paste; the shell material of the microcapsule powder includes water-soluble high molecular polymer, and the core material includes low boiling point alkanes;

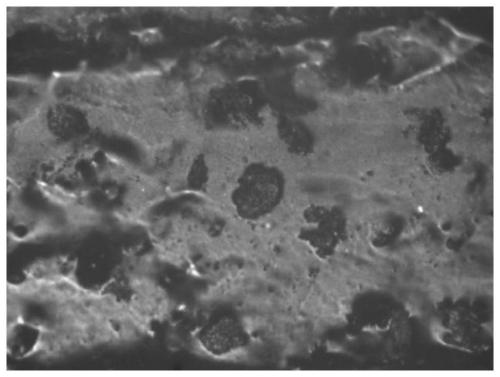

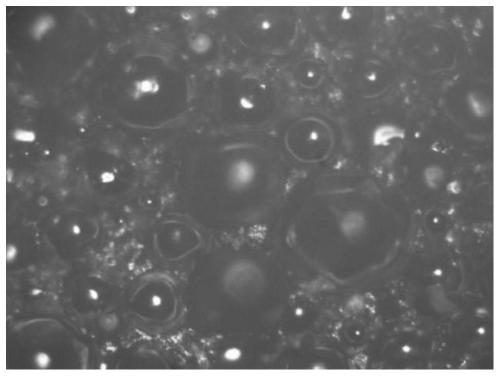

[0038] Step (2) Then enter the 70-100°C drying tunnel and heat for 2-5 minutes to quickly vaporize and expand the low boiling point alkane, break the shell material, and form multiple airtight bubbles in the polyacrylate resin;

...

Embodiment 1

[0046] The ratio of the raw materials of the similar microcapsule powder: the following are all composed of parts by mass, 1 part of water-soluble polymer methyl cellulose, 100 parts of deionized water, and 3 parts of neopentane. Preparation process: fully stir and disperse the water-soluble polymer methyl cellulose and deionized water to form a uniform mixed solution, cool to 4-8°C; then mix neopentane with the above mixed solution, and emulsify through an emulsifying pump For treatment, the diameter of the emulsion is controlled to 2-5μm. Then the emulsion is subjected to vacuum freeze-drying treatment to obtain microcapsule-like powder.

[0047] Glue ratio: the following are all parts by mass, 1 part of microcapsule powder, 20 parts of diluted monomer containing carbon-carbon double bonds, 100 parts of polyacrylate resin containing carbon-carbon double bonds, 30 parts of liquid rosin ester , 1 part photoinitiator, 1 part inhibitor, colorless paste. Among them, the diluent mo...

Embodiment 2

[0053] The ratio of the raw materials of the microcapsule-like powder: the following are all composed of parts by mass, 3 parts of water-soluble polymer, 150 parts of deionized water, 4 parts of neopentane, and 1 part of isopentane. Preparation process: fully stir and disperse the water-soluble polymer and deionized water to form a uniform mixed solution, and cool to 4-8°C; then mix neopentane and isopentane with the above mixed solution, and emulsify through an emulsifying pump For treatment, the diameter of the emulsion is controlled to 2-5μm. Then the emulsion is subjected to vacuum freeze-drying treatment to obtain a microcapsule-like powder; wherein the water-soluble polymer is 1 part of carboxymethyl cellulose, 1 part of ethyl cellulose and 1 part of hydroxyethyl cellulose.

[0054] Glue ratio: The following are all parts by mass, 20 parts of microcapsule powder, 50 parts of diluted monomer containing carbon-carbon double bonds, 200 parts of polyacrylate resin containing ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com