Waterproof polyborosiloxane impact-resistant damping material and preparation method thereof

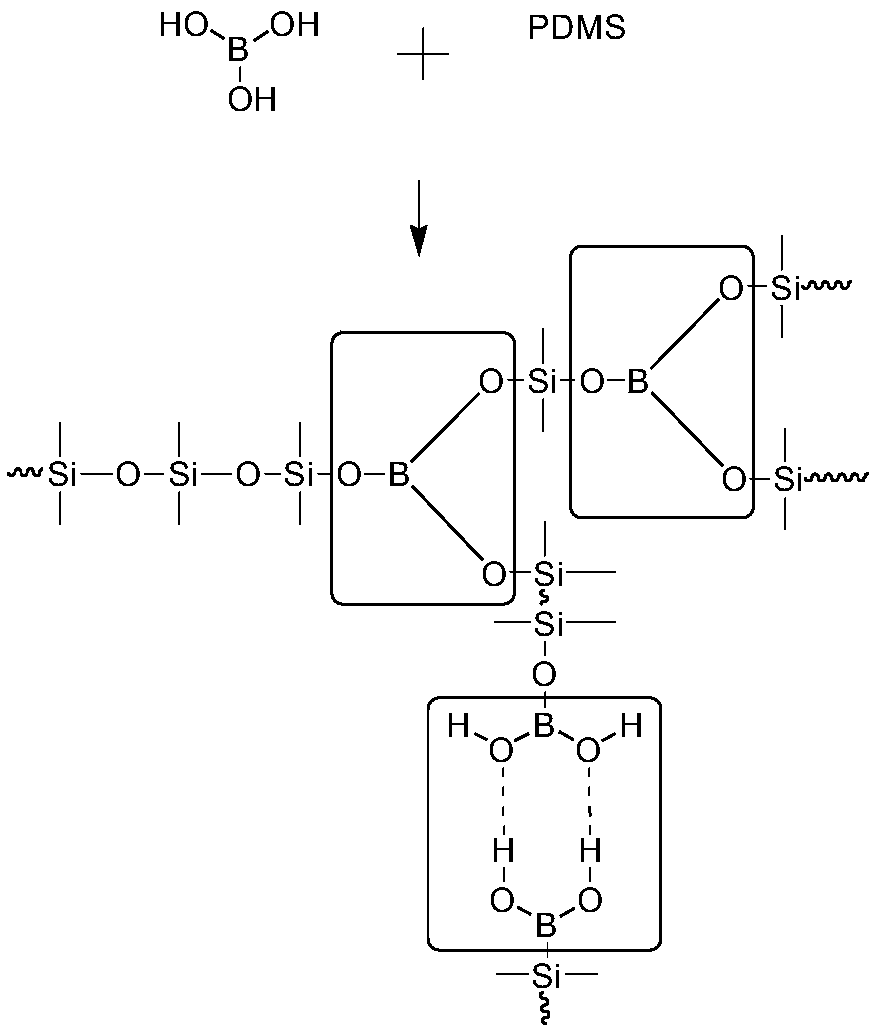

The technology of polyborosiloxane and damping material is applied in the field of waterproof polyborosiloxane anti-shock damping material and its preparation, which can solve the problem that the anti-shock damping effect cannot be achieved, the damping performance is reduced, and the polyborosiloxane can be changed. alkane viscoelastic properties and other issues, to avoid hydrolysis problems, high anti-damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method of the waterproof polyborosiloxane impact damping material described in the above technical solution, comprising:

[0053] The polyborosiloxane-based material is mixed with the water-absorbing material to obtain a waterproof polyborosiloxane anti-shock damping material.

[0054] In the present invention, it is preferable to grind the water-absorbing material first, and then physically blend it with the polyborosiloxane-based material. In the present invention, there is no special limitation on the physical blending method, and the mixing can be carried out according to the mixing means well known to those skilled in the art, such as using an internal mixer for mixing. In the present invention, the mixing temperature is not particularly limited, room temperature is enough, specifically 20-40°C. After mixing, the water-absorbing material particles are uniformly dispersed on the surface and inside of the polyborosil...

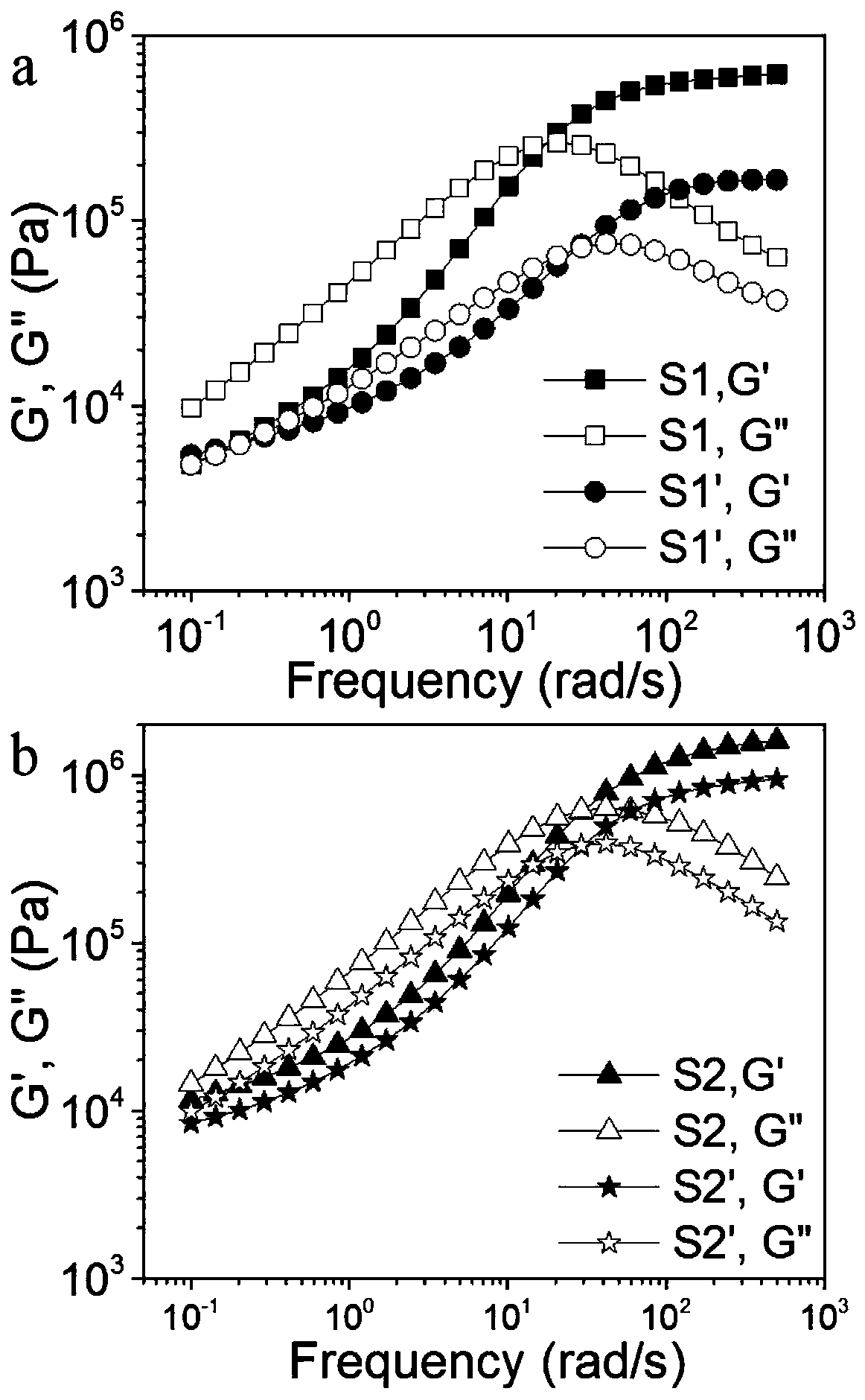

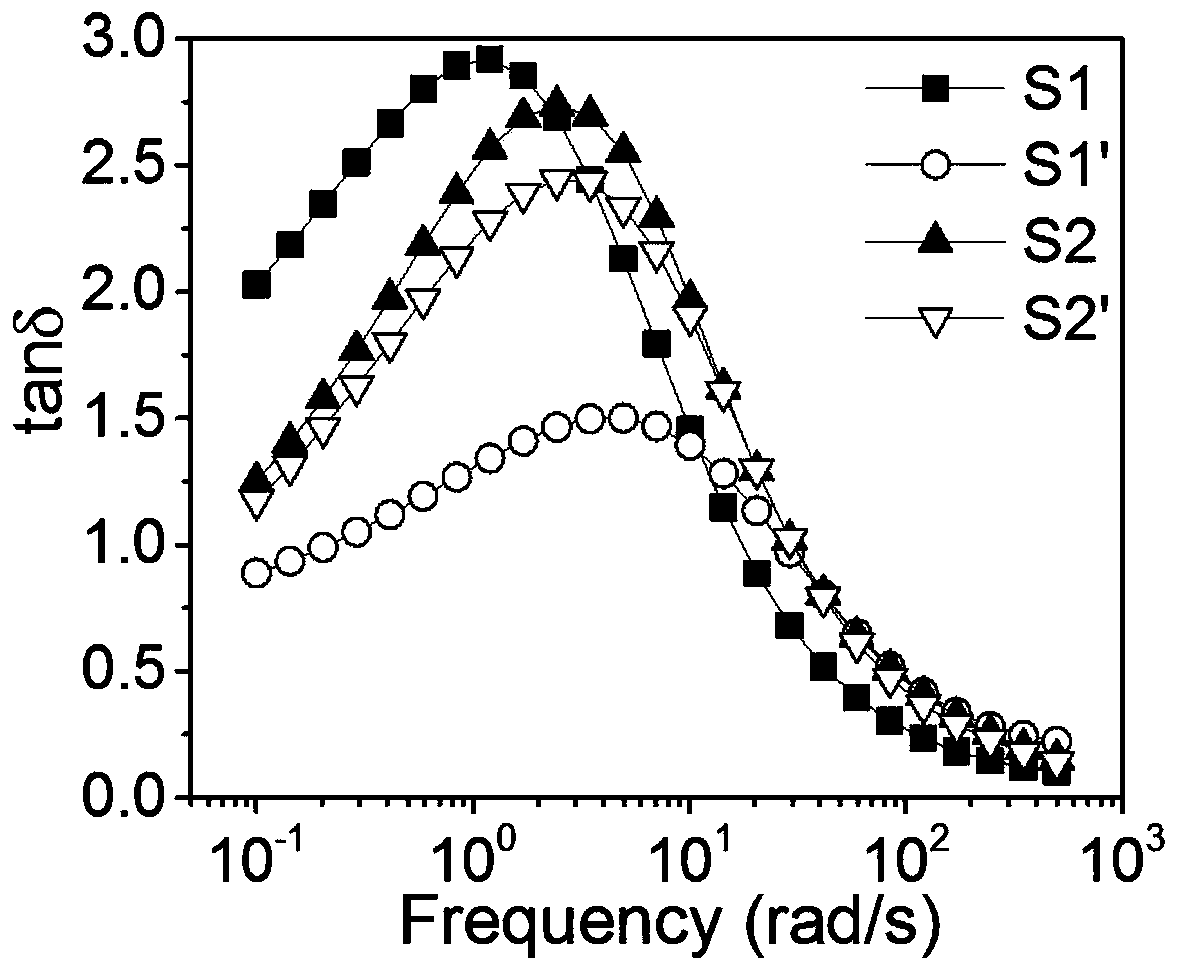

Embodiment 1

[0058] Get 26.6mg boric acid and add three-neck bottle, according to stoichiometric ratio r=1 (the molar ratio of boric acid and the terminal hydroxyl group of hydroxyl-terminated polydimethylsiloxane), the hydroxyl-terminated polydimethylsiloxane (kinematic viscosity 100cst ) into a three-necked flask, stirred electromagnetically at room temperature for 2 h, and then heated in an oil bath at 120° C. for 48 h. Wherein, the reaction by-product water is removed by a vacuum distillation device. After the reaction, the polyborosiloxane polymer is obtained by cooling.

Embodiment 2

[0060] Get 3.8mg boric acid and add three-neck bottle, according to stoichiometric ratio r=1 (the molar ratio of boric acid and the terminal hydroxyl group of hydroxyl-terminated polydimethylsiloxane), the hydroxyl-terminated polydimethylsiloxane (kinematic viscosity 750cst , 3500cst, the molar ratio of the two viscosity substances is 1:1) into a three-neck flask, electromagnetically stirred at room temperature for 2h, and then heated in an oil bath at 120°C for 48h. Wherein, the reaction by-product water is removed by a vacuum distillation device. After the reaction, the polyborosiloxane polymer is obtained by cooling.

[0061] Get 90 parts of gained polyborosiloxane polymer and 10 parts of water-absorbing resin SAP1 of sodium polyacrylate class of German Evonik (Evonik) company, use internal mixer to mix uniformly, obtain waterproof polyborosiloxane anti-impact damping material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com