Sheet shaped yarn pinches slop padding method and apparatus

A yarn shrinking technology, which is applied in the field of yarn padding and yarn shrinking padding devices, can solve the inconsistency of the amount of liquid on the edge of the sheet yarn, increase the length of the transitional color difference of the yarn, and reduce the dipping tank Volume and other issues, to achieve the effect of improving dyeing uniformity, solving the problem of hydrolysis, and reducing the color difference between front and back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

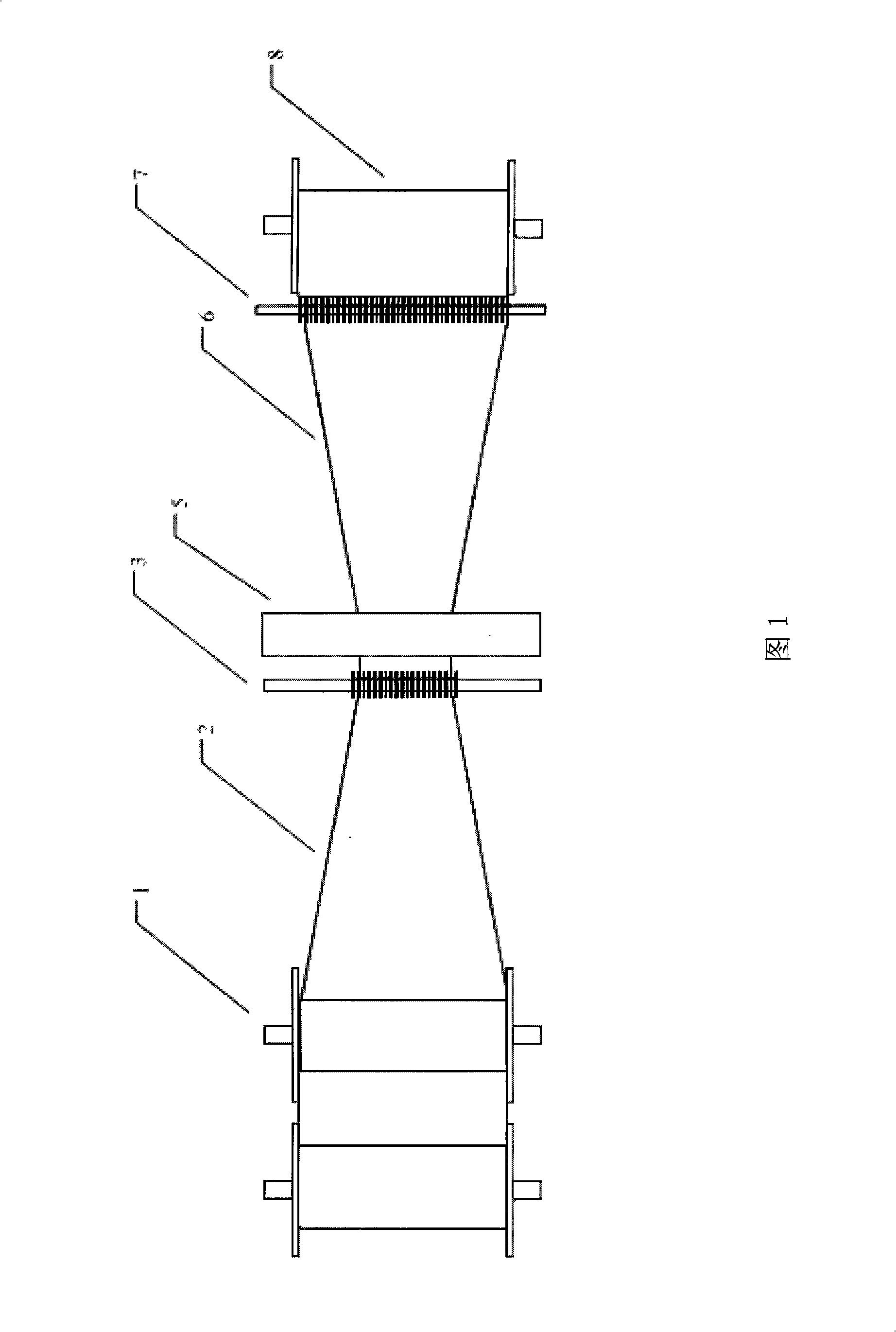

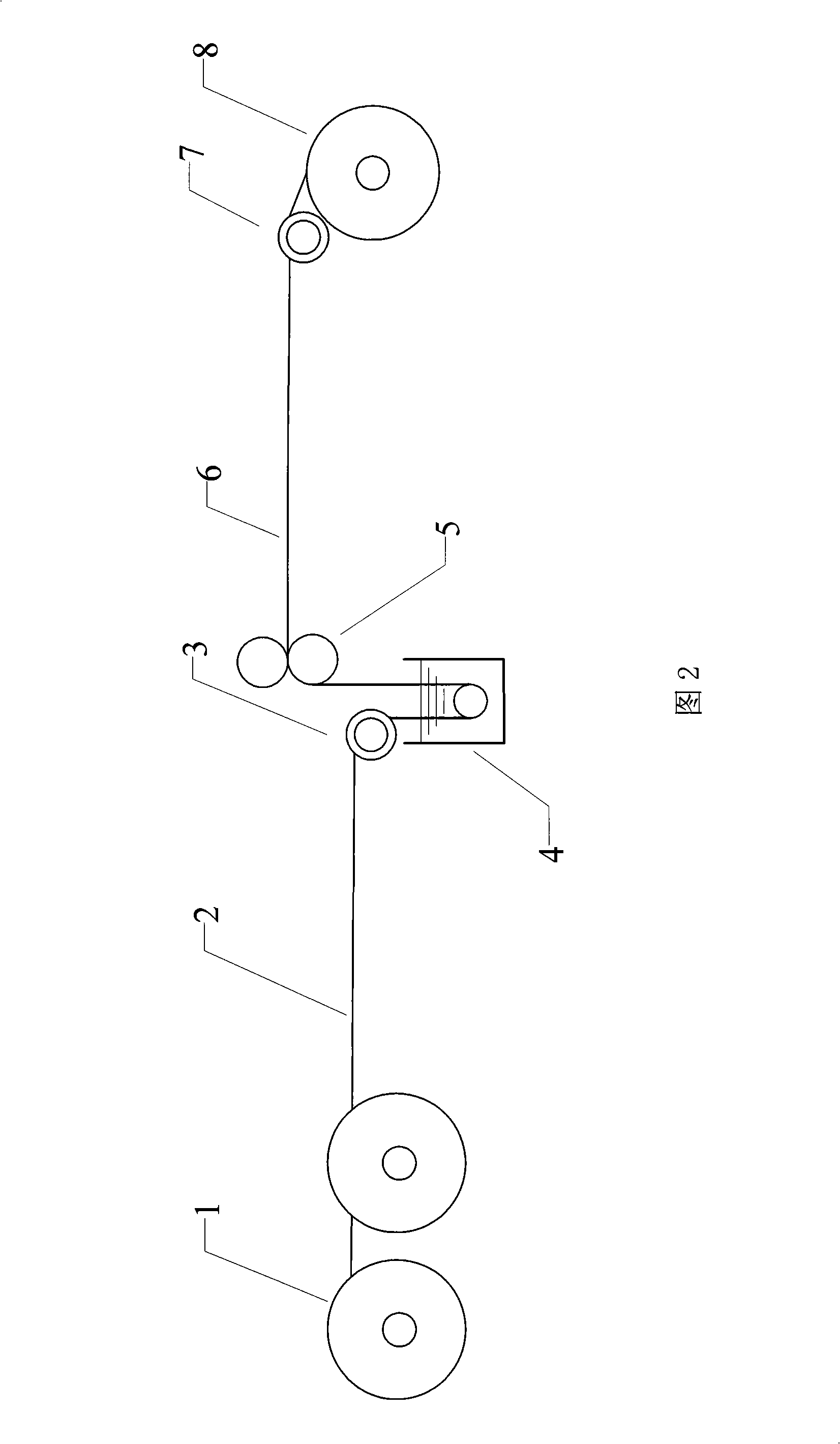

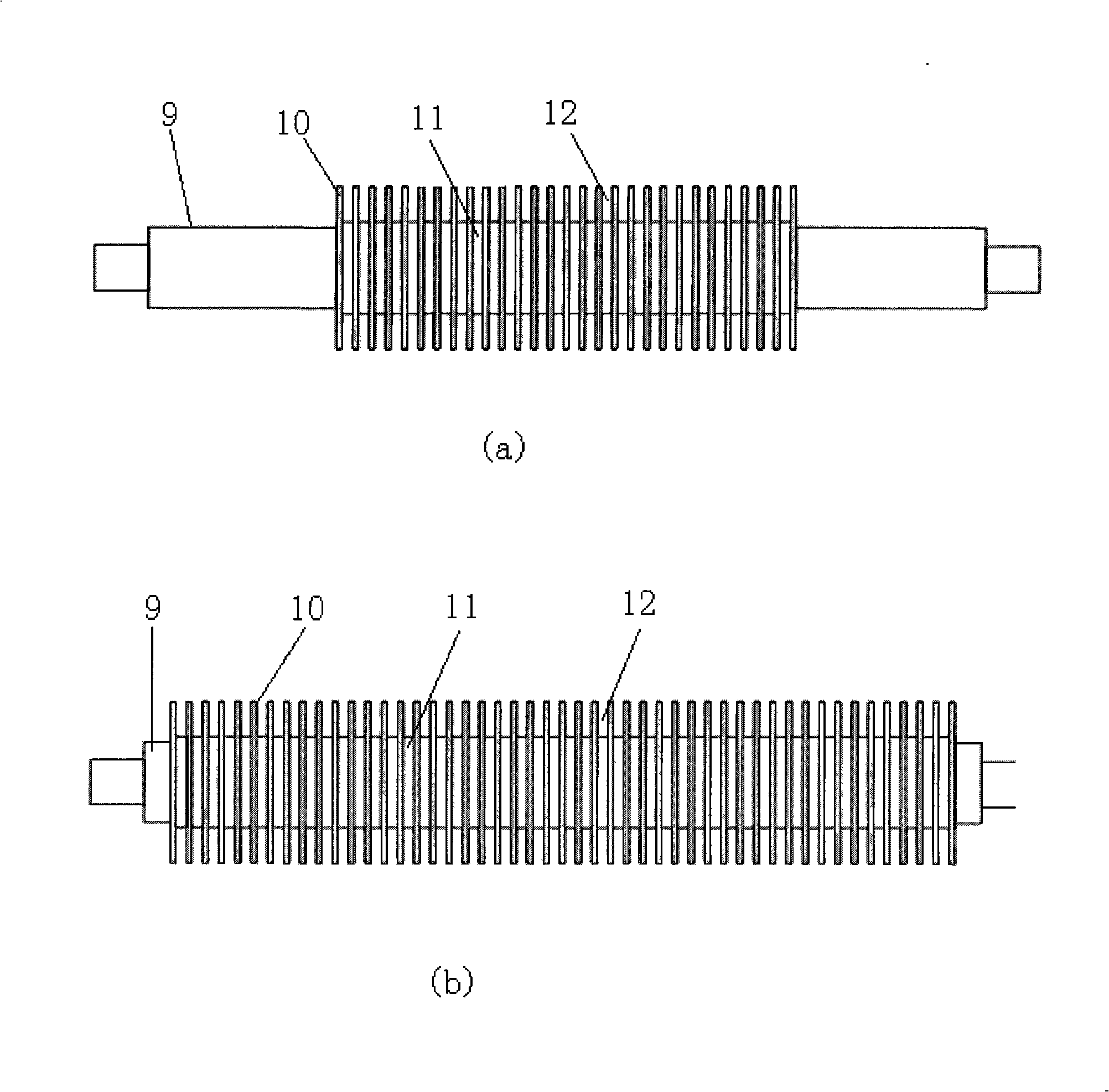

[0030] The sheet yarn shrinking and padding device shown in Figure 1 and 2 is mainly composed of a shrinking roller, a dipping tank, a padding car and an expanding roller. Narrowing roller 3, the unwinding warp beam is dynamically connected to the shrinking roller by sheet yarn, the necking roller is dynamically connected to the entrance of the dipping tank by sheet yarn, and the exit yarn of the dipping tank is dynamically connected to the rolling car, at the winding inlet end Expanding roll 7 is set, padding car is dynamically connected with expanding roll, and expanding roll is dynamically connected with winding warp beam. Neck rolls and expander rolls such as image 3 Shown in (a), (b), be respectively along guide roller 9 roll surface circumferential directions to be alternately installed with big disc 11 and small disc 10, form the groove 12 that yarn runs between two big garden discs. The effective length of the expanding roll is greater than the effective length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com