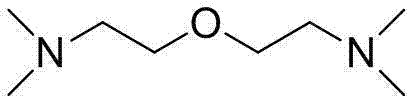

Synthetic method of bis-(2-dimethylaminoethyl)ether

The technology of a dimethylaminoethyl group and a synthesis method is applied in the synthesis field of organic compounds, and can solve the problems of cumbersome feeding method of sulfur trioxide, unfriendly environment of sulfur trioxide, large recovery and processing capacity, etc., and achieves speeding up the etherification reaction. Speed, reduction of toluene extraction steps, the effect of fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, a kind of synthetic method of bis(2-dimethylaminoethyl) ether, take 2-dimethylethanolamine as starting raw material, carry out the following steps successively:

[0042] 1), 2-dimethylethanolamine chlorination:

[0043] Put 66g (0.55mol) of thionyl chloride in a 250mL three-necked flask, add 44.5g (0.5mol) of 2-dimethylethanolamine dropwise, the temperature is controlled at 10°C, and the dropwise is completed within 0.5h. After dropping, the temperature was raised to 30°C, and the reaction was stopped after 2 hours. The resulting reaction solution was removed by rotary evaporation under reduced pressure at room temperature under 10KPa to remove light components (the light components mainly include thionyl chloride, sulfur dioxide, hydrogen chloride), and the precipitated solid was dried (dried at 70°C) To constant weight, about 70.6g of chloride hydrochloride was obtained.

[0044] (2) Put 133.5g (1.5mol) of 2-dimethylethanolamine in a 500mL three-necked...

Embodiment 2

[0049] Embodiment 2, a kind of synthetic method of bis(2-dimethylaminoethyl) ether, take 2-dimethylethanolamine as starting material, carry out the following steps successively:

[0050] (1) Put 59.5g (0.50mol) of thionyl chloride in a 250mL three-necked flask, add 44.5g (0.50mol) of 2-dimethylethanolamine dropwise, and control the temperature at 10°C, and drop it within 0.5h. After dropping, the temperature was raised to 30°C, and the reaction was stopped after 2 hours. The resulting reaction solution was removed by rotary evaporation under reduced pressure at room temperature under 10KPa to remove light components (the light components mainly include thionyl chloride, sulfur dioxide, hydrogen chloride), and the precipitated solid was dried (dried at 70°C) To constant weight, about 68.4g of chloride hydrochloride was obtained.

[0051] (2) Put 133.5g (1.5mol) of 2-dimethylethanolamine in a 500mL three-necked flask, add 24.2g (1.05mol) of sodium metal, the reaction is exother...

Embodiment 3

[0054] Embodiment 3, a kind of synthetic method of bis(2-dimethylaminoethyl) ether, take 2-dimethylethanolamine as starting material, carry out the following steps successively:

[0055] (1) Put 119g (1.0mol) of thionyl chloride in a 250mL three-necked flask, add 44.5g (0.5mol) of 2-dimethylethanolamine dropwise, and control the temperature at 10°C, and drop it within 0.5h. After dropping, the temperature was raised to 30°C, and the reaction was stopped after 2 hours. The resulting reaction solution was removed by rotary evaporation under reduced pressure at room temperature under 10KPa to remove light components (the light components mainly include thionyl chloride, sulfur dioxide, hydrogen chloride), and the precipitated solid was dried (dried at 70°C) To constant weight, about 71.1g of chloride hydrochloride was obtained.

[0056] (2) Put 133.5g (1.5mol) of 2-dimethylethanolamine in a 500mL three-necked flask, add 24.2g (1.05mol) of sodium metal, the reaction is exothermic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com