Method for processing sesame oil by stone mill

A processing method and technology of sesame oil, which are applied in the directions of edible oil/fat, fat oil/fat production, and fat oil/fat refining, etc., can solve the problems of protein denaturation in sesame, affecting the yield of sesame oil, affecting the activity of sesame oil, etc. Avoid the denaturation of sesame protein and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

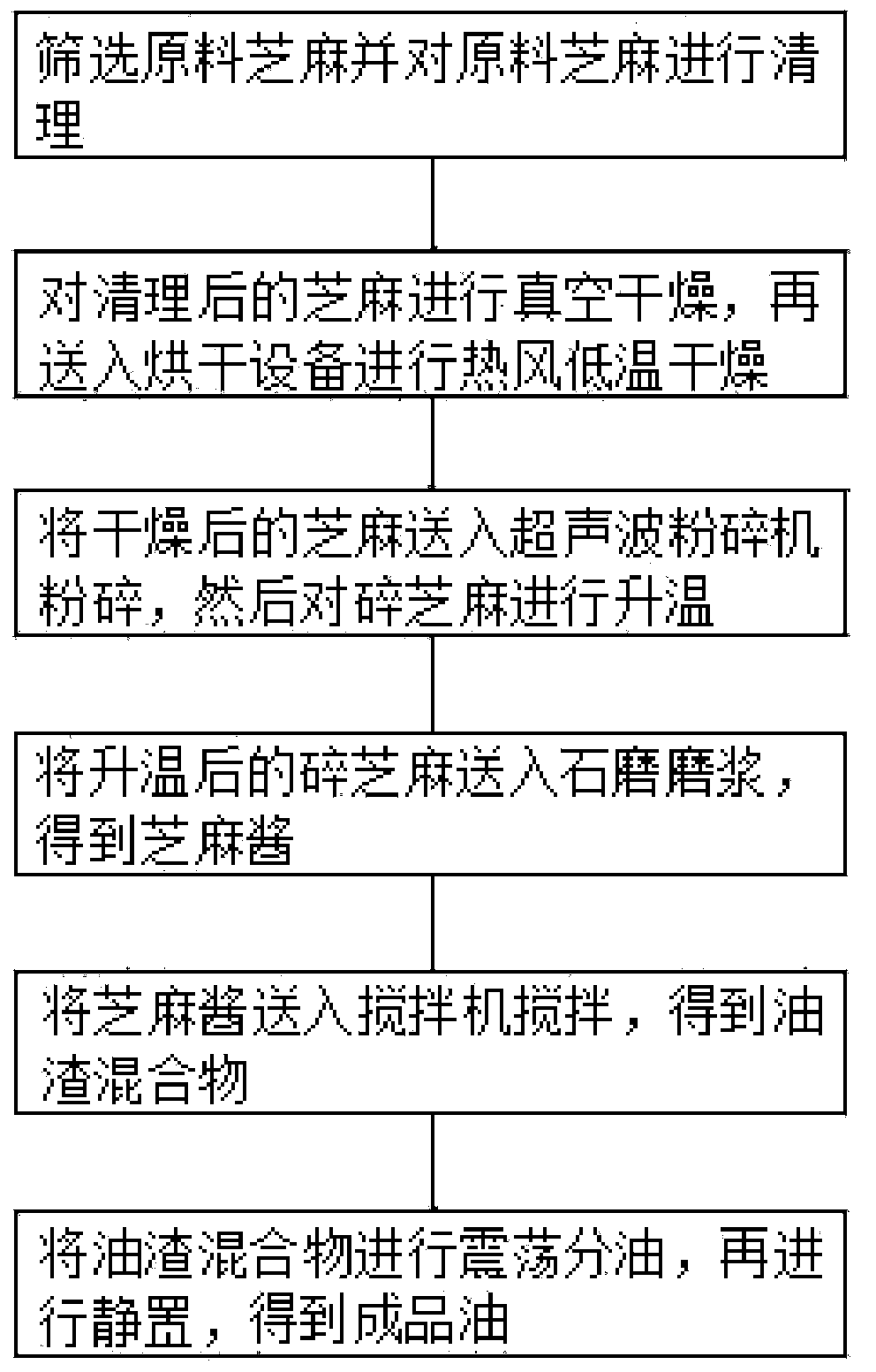

Image

Examples

Embodiment 1

[0025] (1), first select the raw sesame seeds, and then soak and clean the selected raw sesame seeds. The specific steps for cleaning are as follows:

[0026] a. First feed the raw sesame into the screening machine for winnowing, and then vibrating screening;

[0027] b. Soak the sesame seeds screened in step a in water for 1.5 hours, and control the moisture content of the sesame seeds at 30%;

[0028] (2), the sesame after soaking and cleaning is sent to the vacuum equipment for vacuum drying, and then the sesame is dried with hot air and low temperature, the vacuum low temperature drying time is controlled at 4.5 hours, and the temperature of the hot air is controlled at 50 degrees;

[0029] (3), the dried sesame is sent to the ultrasonic pulverizer for pulverization, then the crushed sesame is heated up, the ultrasonic frequency of the supersonic pulverizer is 600W, and the time for ultrasonic pulverization of the sesame is more than 15 minutes, and the temperature of the ...

Embodiment 2

[0034] (1), first select the raw sesame seeds, and then soak and clean the selected raw sesame seeds. The specific steps for cleaning are as follows:

[0035] a. First feed the raw sesame into the screening machine for winnowing, and then vibrating screening;

[0036] b. Soak the sesame seeds screened in step a in water for 1.5 hours, and control the moisture content of the sesame seeds at 30%;

[0037] (2), the sesame after soaking and cleaning is sent to the vacuum equipment for vacuum drying, and then the sesame is dried with hot air and low temperature, the vacuum low temperature drying time is controlled at 4.5 hours, and the temperature of the hot air is controlled at 50 degrees;

[0038] (3), the dried sesame is sent to the ultrasonic pulverizer for pulverization, then the crushed sesame is heated up, the ultrasonic frequency of the supersonic pulverizer is 600W, and the time for ultrasonic pulverization of the sesame is more than 15 minutes, and the temperature of the ...

Embodiment 3

[0043] (1), first select the raw sesame seeds, and then soak and clean the selected raw sesame seeds. The specific steps for cleaning are as follows:

[0044] a. First feed the raw sesame into the screening machine for winnowing, and then vibrating screening;

[0045] b. Soak the sesame seeds screened in step a in water for 1.5 hours, and control the moisture content of the sesame seeds at 30%;

[0046] (2), the sesame after soaking and cleaning is sent to the vacuum equipment for vacuum drying, and then the sesame is dried with hot air and low temperature, the vacuum low temperature drying time is controlled at 4.5 hours, and the temperature of the hot air is controlled at 50 degrees;

[0047] (3), the dried sesame is sent to the ultrasonic pulverizer for pulverization, then the crushed sesame is heated up, the ultrasonic frequency of the supersonic pulverizer is 600W, and the time for ultrasonic pulverization of the sesame is more than 15 minutes, and the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com