Preparation method and applications of N-g-C3N4 visible light catalytic material

A technology of n-g-c3n4 and catalytic materials, which is applied in the field of environment and chemistry, can solve problems such as limiting practical applications, and achieve the effects of inhibiting recombination, good bacteriostasis, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] This embodiment provides a kind of N-g-C 3 N 4 (Nitrogen-enriched carbon nitride) preparation method, comprising the following steps:

[0030] (1) After mixing the nitrogen-rich precursor and melamine, they are fully ground to obtain a mixture, wherein the mass ratio of the nitrogen-rich precursor to melamine can be 0.05:3-0.5:3. The nitrogen-rich precursor can be 3-amino-1,2,4 triazole or 5 amino-1H-4 azole. Preferably, the mass ratio of the nitrogen-rich precursor to the melamine is 0.1:3˜0.3:3.

[0031] (2) Put the homogeneously ground mixture into a muffle furnace, raise the temperature to 500°C and calcine at a constant temperature for two hours, and after natural cooling, grind the calcined product to obtain N-g-C 3 N 4 . The heating rate is 5-10°C / min.

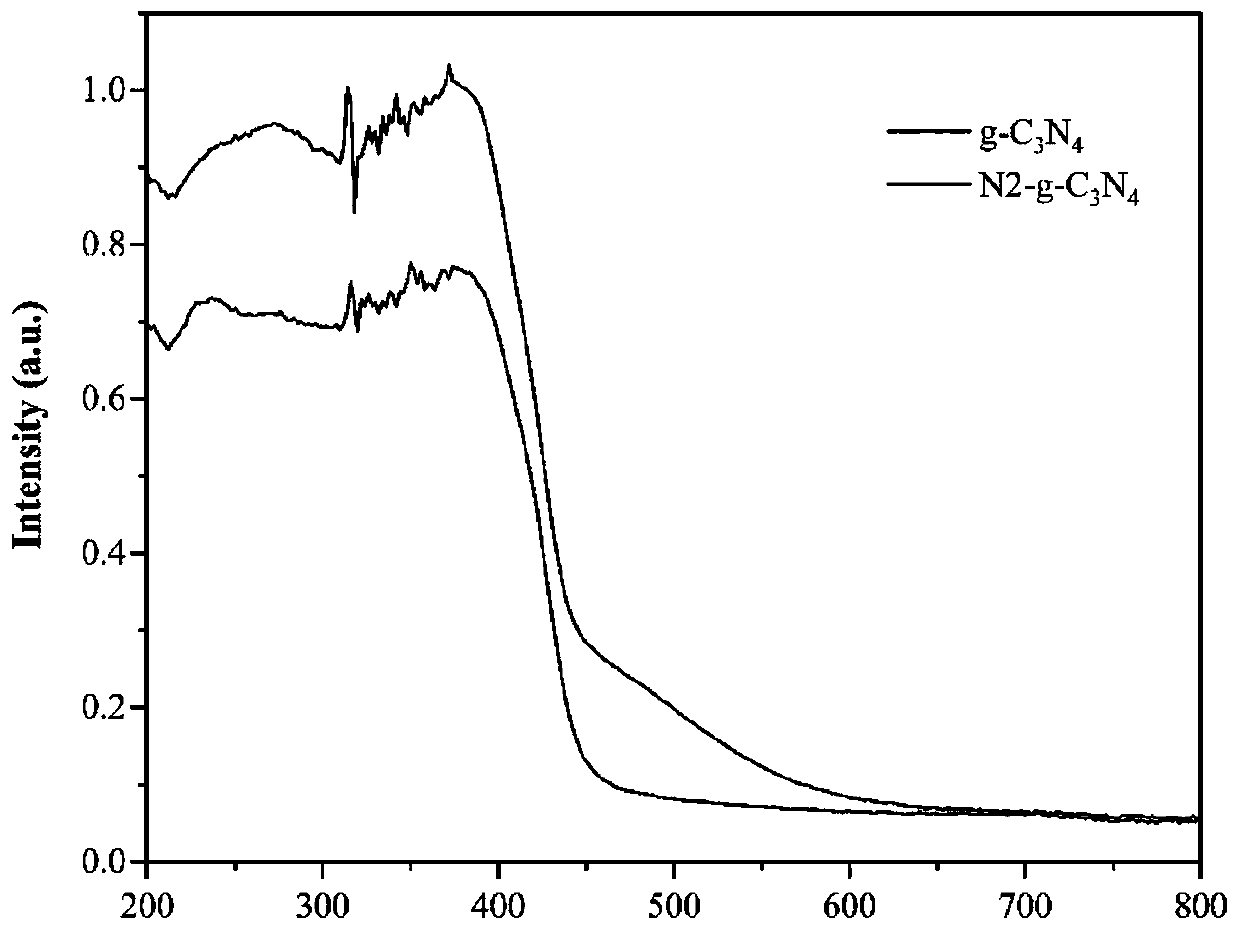

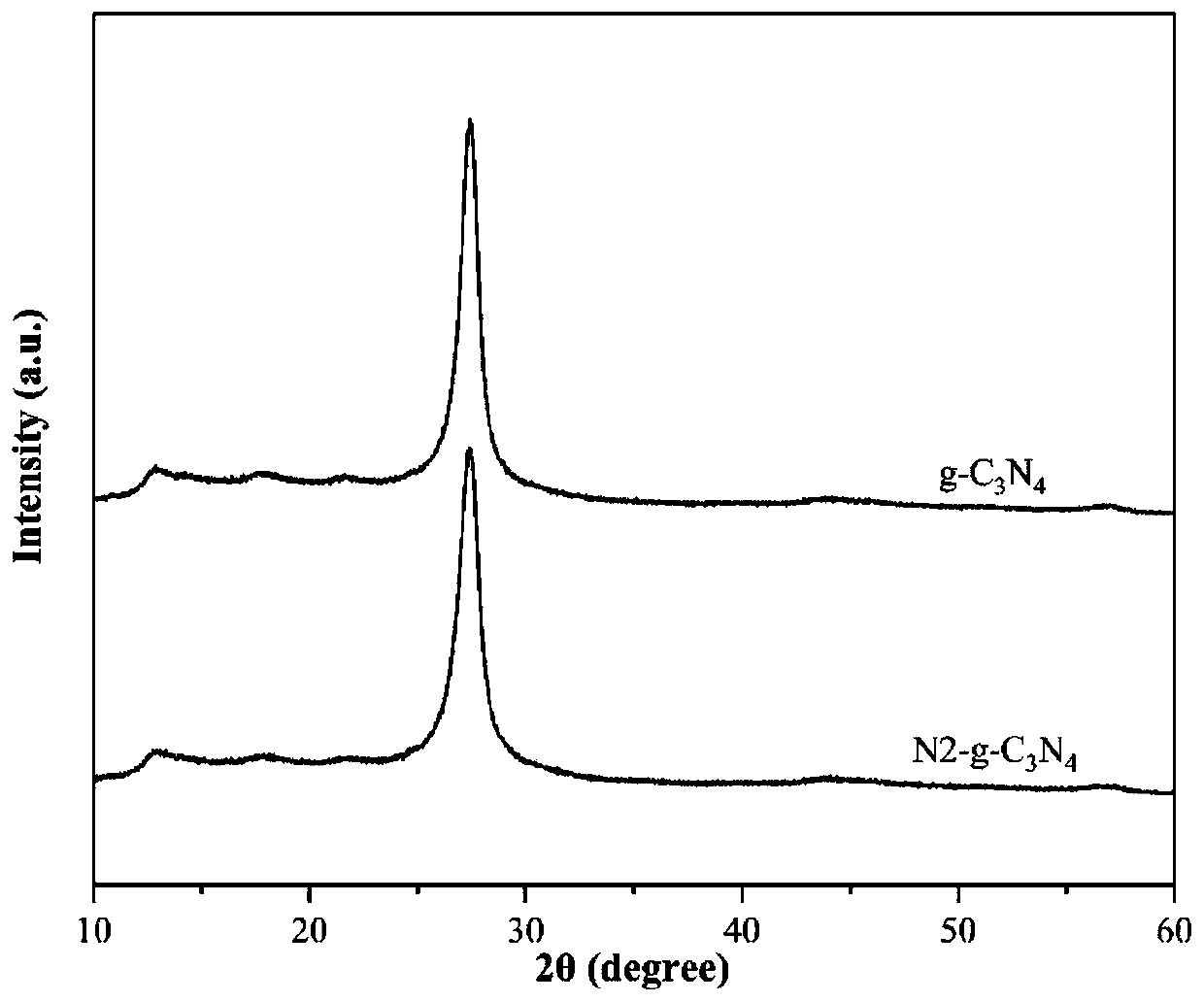

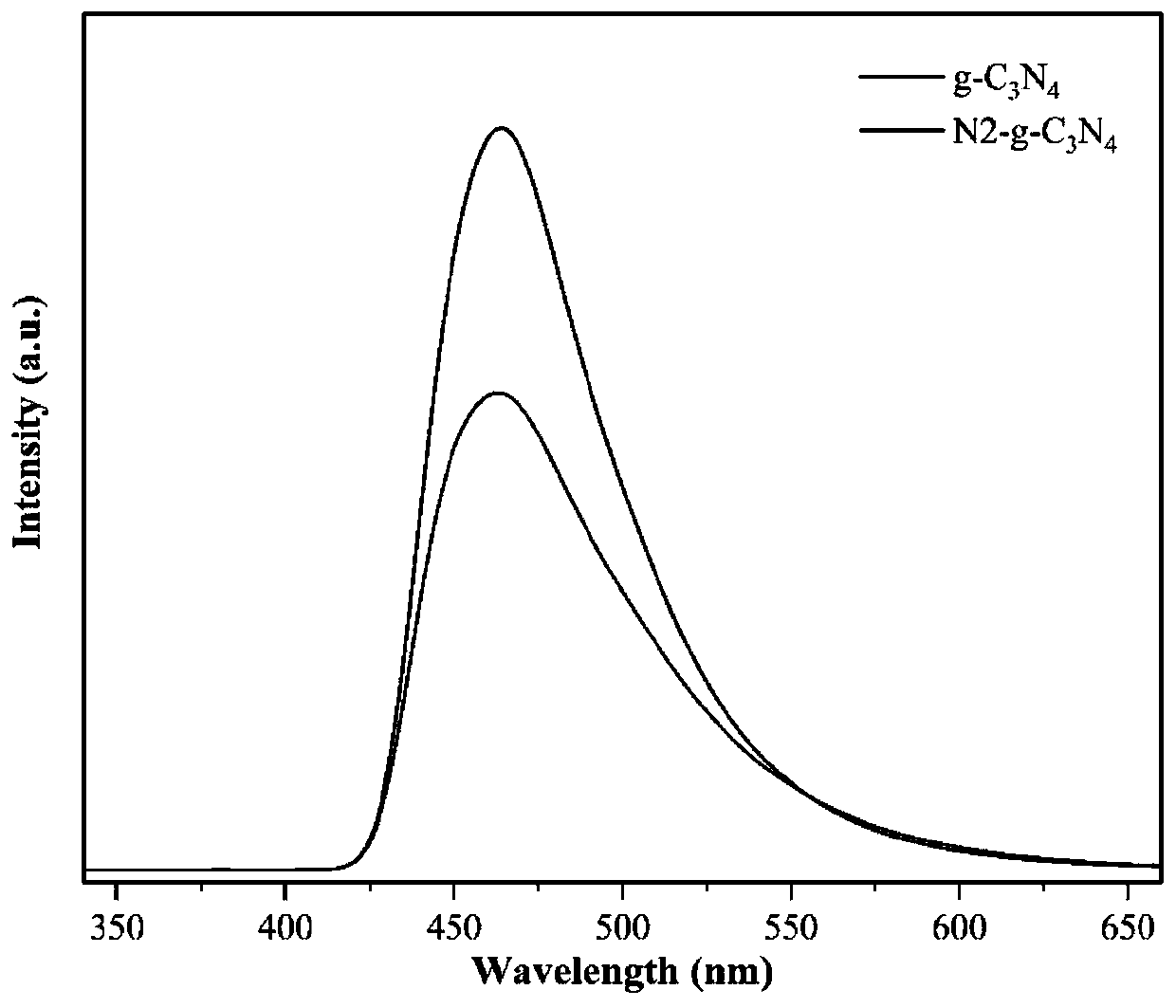

[0032] Specifically, in this embodiment, the mass ratio of the nitrogen-rich precursor 3-amino-1,2,4-triazole to melamine is 0.2:3. figure 1 For the N-g-C obtained by the method of this embodiment 3 N 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com