Flexible battery and preparation method thereof

A flexible battery and flexible technology, applied to the electrodes of primary batteries, hybrid batteries, battery electrodes, etc., can solve the problems of poor safety and stability, low specific capacity of flexible air batteries, etc., achieve high stability, increase specific capacity, and reduce interface The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

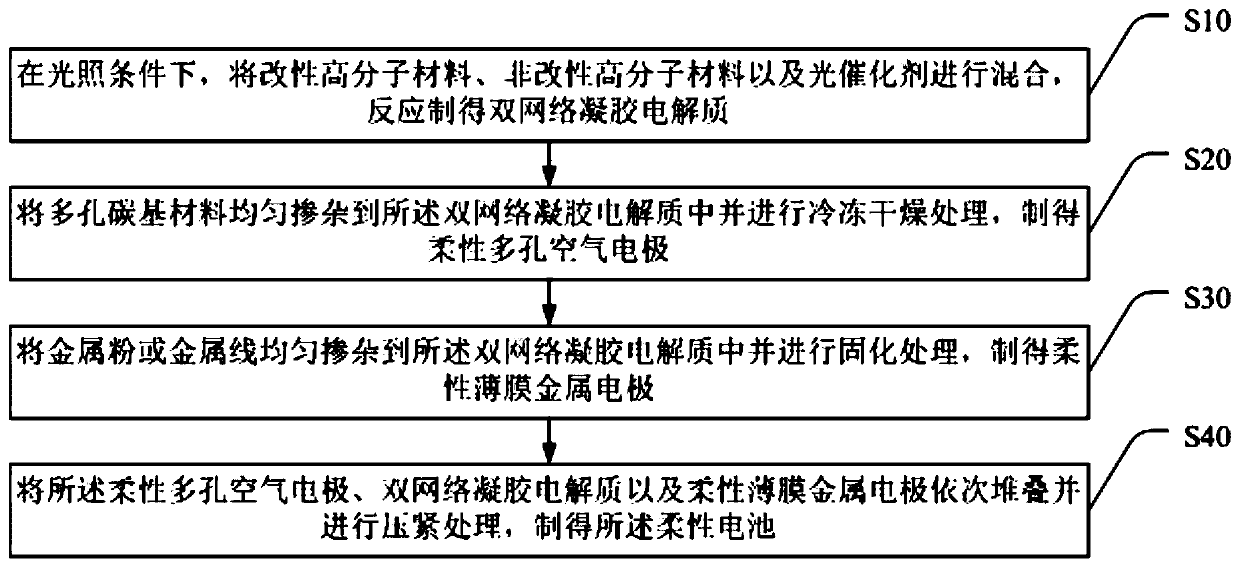

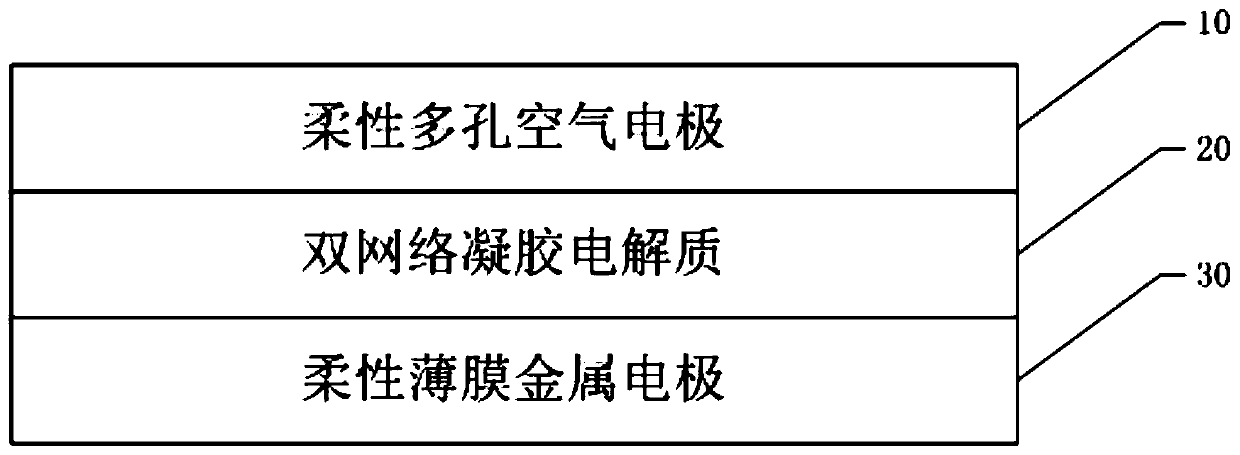

Method used

Image

Examples

Embodiment 1

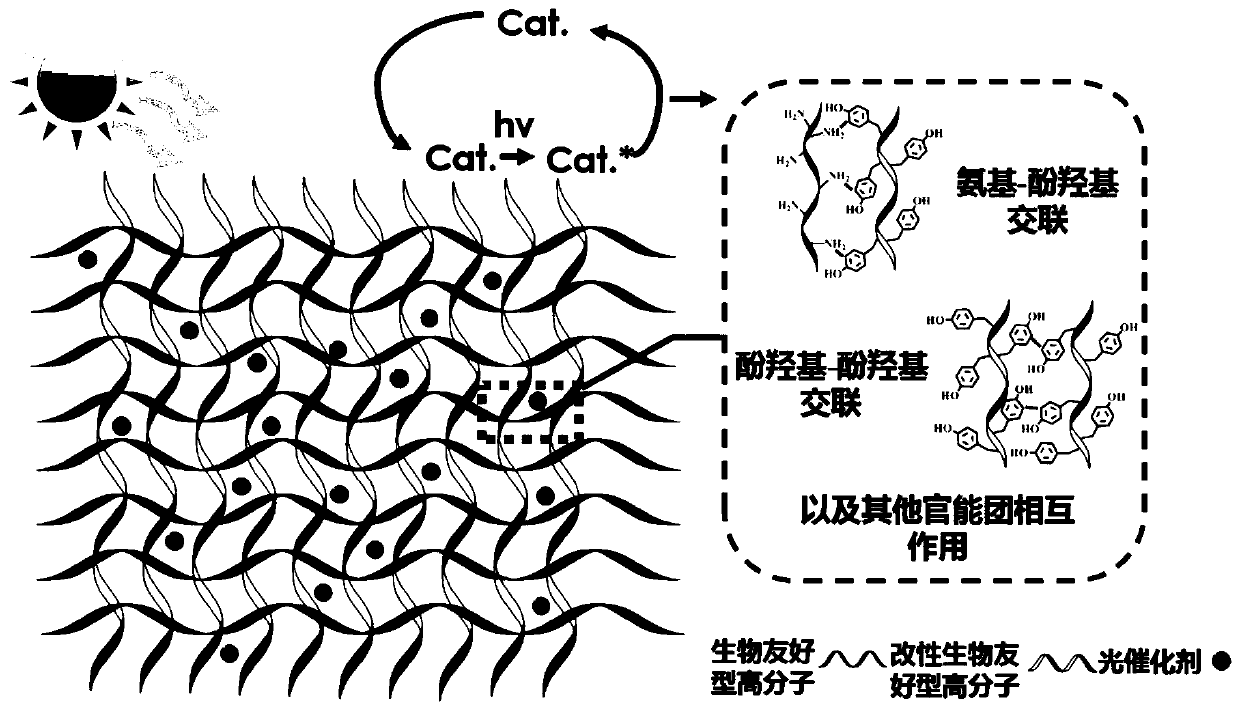

[0060] Preparation of gel electrolyte: activator 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) were used to react with sodium alginate The carboxyl group is activated, and the activated sodium alginate reacts with p-hydroxybenzylamine at room temperature and acidic conditions with a pH of 6.5 to prepare modified sodium alginate. Figure 4 is the change diagram of the ultraviolet absorption peak before and after the modification of sodium alginate, and the reaction equation of the modification process is Then, mix the modified sodium alginate and chitin at a molar ratio of 1:5, stir evenly, add a photocatalyst, illuminate under visible light, and form a double-network gel electrolyte through cross-linking, and the double-network The SEM image of the gel electrolyte is shown in Figure 5 Shown; The EDS element distribution figure of described double network gel electrolyte is as Figure 6 shown.

[0061] Preparation of flexi...

Embodiment 2

[0065] Preparation of gel electrolyte: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC·HCL) and N-hydroxysuccinimide (NHS) The carboxyl group of sodium is activated, and the activated sodium alginate reacts with p-hydroxybenzylamine at room temperature and acidic conditions with a pH of 6.5 to prepare modified sodium alginate. The reaction equation is Then, mix the modified sodium alginate and sodium polyacrylate at a molar ratio of 1:5, stir evenly, add a photocatalyst, illuminate under visible light, and form a double network gel electrolyte through crosslinking. The SEM image of the network gel electrolyte is as follows Figure 7 As shown, the EDS element distribution diagram of the double network gel electrolyte is as follows Figure 8 As shown, the stretching diagram of the double network gel electrolyte is as follows Figure 9 shown.

[0066] Preparation of flexible porous air electrode: The method of preparing modified sodium alginate is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com