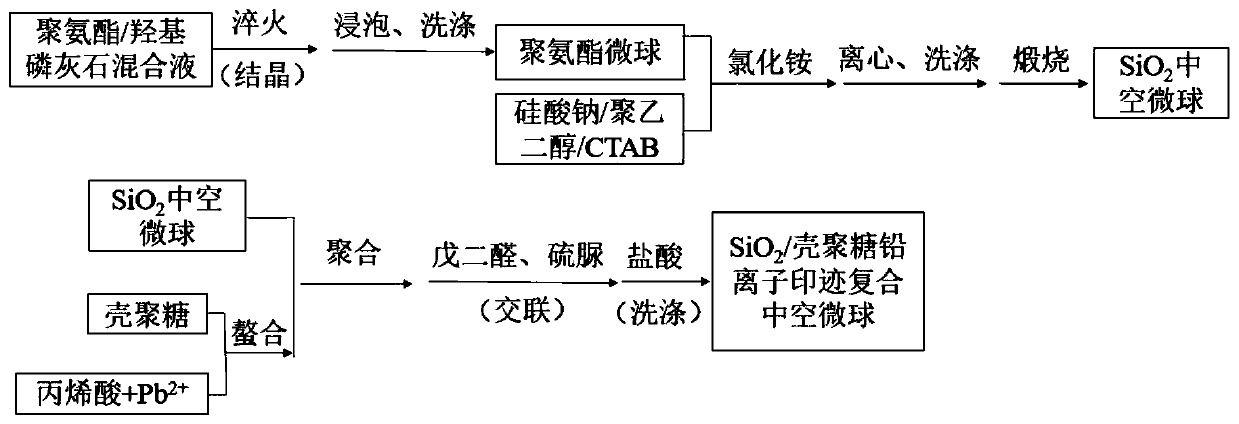

Preparation method of SiO2/chitosan-based lead ion imprinted hollow microspheres

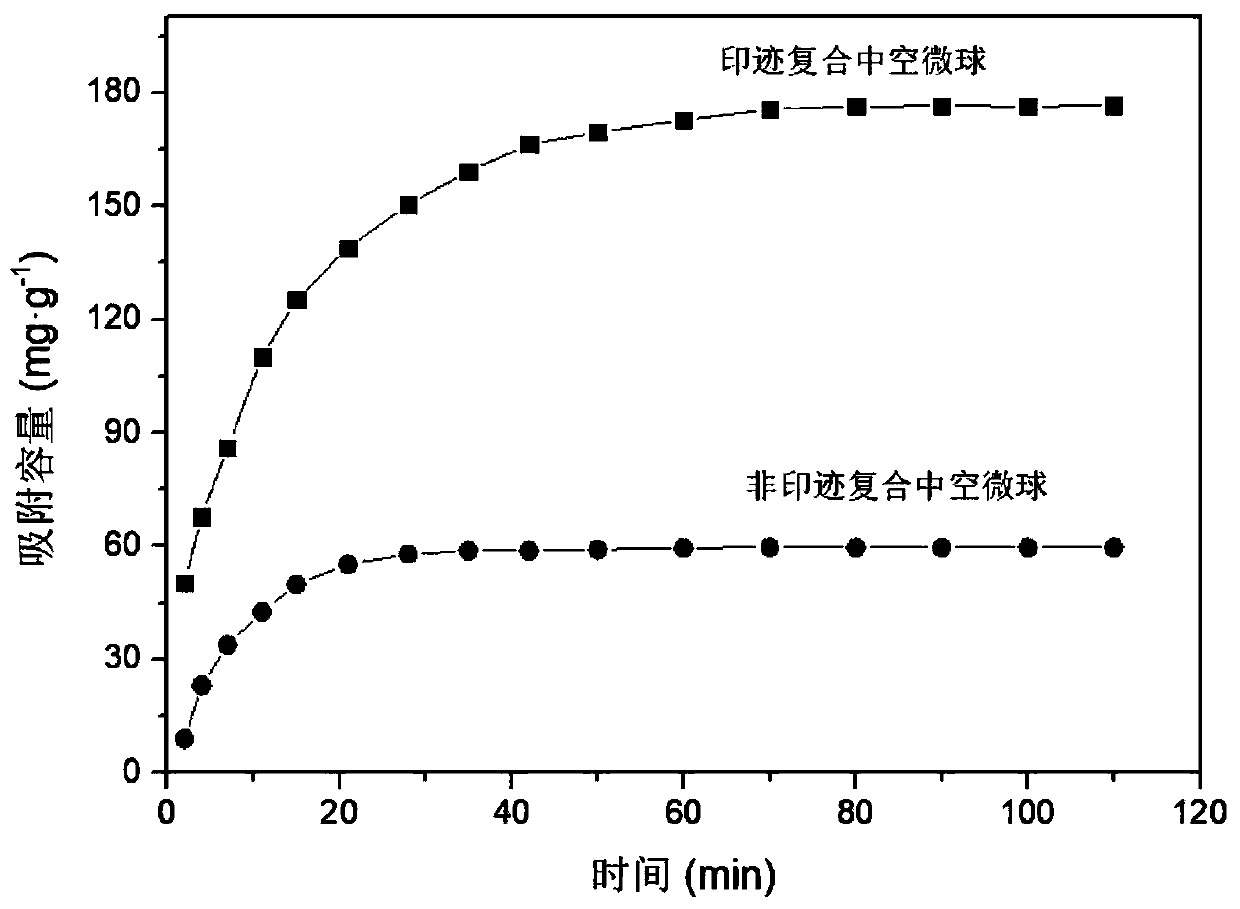

A lead ion and chitosan technology is applied in the field of preparation of SiO2/chitosan-based lead ion imprinted composite hollow microspheres, which can solve the problems of reduced adsorption capacity and loss of reactivity of chitosan, and achieves improved adsorption performance, The effect of high porosity and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The preparation of the quenching liquid is as follows: add 1 g of polyurethane, 3 g of acetone, and 12 g of tetrahydrofuran into a 100 mL three-neck flask, stir magnetically at 50 ° C for 2 h, and dissolve to form a homogeneous solution. 0.02 g of nano-hydroxyapatite was added to the homogeneous solution, and magnetically stirred at room temperature to obtain a quenching solution. Put the quenching solution in a refrigerator pre-cooled to -20°C for 4 hours. After quenching, quickly take it out from the refrigerator, put it in a 500mL ice-water mixture, remove acetone and tetrahydrofuran, repeatedly change distilled water, wash, and freeze-dry to obtain polyurethane Microspheres.

[0038] (2) Add 10g of ethanol, 30g of distilled water, 1.2g of sodium silicate, 0.1g of polyethylene glycol, and 0.01g of hexadecyltrimethylammonium bromide into a three-necked flask, and magnetically stir to dissolve. After the dissolution, add 0.5 g polyurethane microspheres, magnetical...

Embodiment 2

[0042](1) The preparation of the quenching solution is as follows: add 1.5 g of polyurethane, 4 g of acetone, and 8 g of tetrahydrofuran into a 100 mL three-neck flask, and stir magnetically at 50 ° C for 2 h to form a homogeneous solution. Add 0.04 g of nano-hydroxyapatite to the homogeneous solution, stir and mix evenly at room temperature to obtain a quenching solution. Put the quenching solution in a refrigerator pre-cooled to -30°C and quench for 5 hours. After quenching, quickly take it out of the refrigerator, put it into 500mL ice-water mixture, remove acetone and tetrahydrofuran, repeatedly change distilled water, wash, and freeze-dry to obtain polyurethane Microspheres.

[0043] (2) Add 25g of ethanol, 30g of distilled water, 1.5g of sodium silicate, 0.1g of polyethylene glycol, and 0.01g of hexadecyltrimethylammonium bromide into a three-necked flask, stir and dissolve with magnetic force. After the dissolution, add 0.5 g polyurethane microspheres, magnetically sti...

Embodiment 3

[0047] (1) The preparation of the quenching solution is as follows: add 1.2 g of polyurethane, 5 g of acetone, and 7 g of tetrahydrofuran into a 100 mL three-neck flask, and stir magnetically at 50 ° C for 2 h to dissolve to form a homogeneous solution. 0.03 g of nano-hydroxyapatite was added to the homogeneous solution, and magnetically stirred at room temperature to obtain a quenching solution. Put the quenching solution in a refrigerator pre-cooled to -25°C and quench for 3 hours. After quenching, quickly take it out of the refrigerator, put it into 500mL ice-water mixture, remove acetone and tetrahydrofuran, repeatedly change distilled water, wash, and freeze-dry to obtain polyurethane Microspheres.

[0048] (2) Add 20g of ethanol, 30g of distilled water, 1.8g of sodium silicate, 0.1g of polyethylene glycol, and 0.01g of hexadecyltrimethylammonium bromide into a three-necked flask, stir and dissolve with magnetic force. After the dissolution, add 0.5 g polyurethane micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com