Glass factory waste gas denitration method

A glass factory, waste gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as incomplete treatment of nitrogen oxides and sulfides, incomplete reaction of waste gas catalysts, limited space for desulfurization and denitrification towers, etc. Achieve the effects of easy promotion and use, short shutdown and installation period, and small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

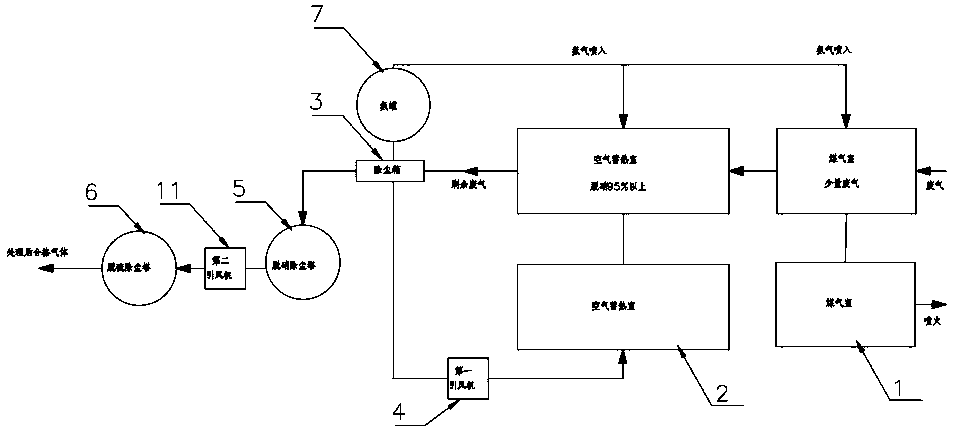

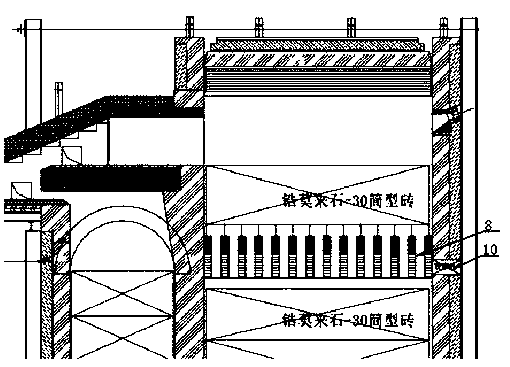

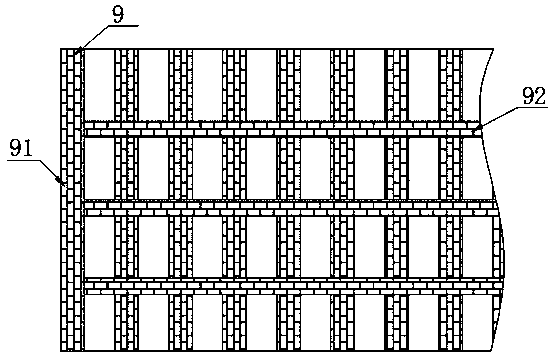

[0029] according to Figure 1-4 The shown method for denitrification of waste gas from a glass factory includes a gas chamber 1, an air heat storage chamber 2 is provided on one side of the gas chamber 1, and a dust removal box 3 is provided at the output end of the air heat storage chamber 2, and the dust removal box 3 and the air heat storage chamber 2 are provided with a return air pipe, the middle part of the air return pipe is provided with a first induced draft fan 4, the output end of the dust removal box 3 is provided with a denitrification dust removal tower 5, and the output end of the denitrification dust removal tower 5 is provided with There is a desulfurization and dust removal tower 6, a second induced draft fan 11 is arranged between the denitrification and dust removal tower 5 and the desulfurization and dust removal tower 6, an ammonia tank 7 is arranged outside the gas chamber 1 and the air heat storage chamber 2, and the gas chamber 1 and the air heat stora...

Embodiment 2

[0044] according to Figure 1-4 The shown method for denitrification of waste gas from a glass factory includes a gas chamber 1, an air heat storage chamber 2 is provided on one side of the gas chamber 1, and a dust removal box 3 is provided at the output end of the air heat storage chamber 2, and the dust removal box 3 and the air heat storage chamber 2 are provided with a return air pipe, the middle part of the air return pipe is provided with a first induced draft fan 4, the output end of the dust removal box 3 is provided with a denitrification dust removal tower 5, and the output end of the denitrification dust removal tower 5 is provided with There is a desulfurization and dust removal tower 6, a second induced draft fan 11 is arranged between the denitrification and dust removal tower 5 and the desulfurization and dust removal tower 6, an ammonia tank 7 is arranged outside the gas chamber 1 and the air heat storage chamber 2, and the gas chamber 1 and the air heat stora...

Embodiment 3

[0059] according to Figure 1-4 The shown method for denitrification of waste gas from a glass factory includes a gas chamber 1, an air heat storage chamber 2 is provided on one side of the gas chamber 1, and a dust removal box 3 is provided at the output end of the air heat storage chamber 2, and the dust removal box 3 and the air heat storage chamber 2 are provided with a return air pipe, the middle part of the air return pipe is provided with a first induced draft fan 4, the output end of the dust removal box 3 is provided with a denitrification dust removal tower 5, and the output end of the denitrification dust removal tower 5 is provided with There is a desulfurization and dust removal tower 6, a second induced draft fan 11 is arranged between the denitrification and dust removal tower 5 and the desulfurization and dust removal tower 6, an ammonia tank 7 is arranged outside the gas chamber 1 and the air heat storage chamber 2, and the gas chamber 1 and the air heat stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com