Alloy component and preparation method thereof

A component and alloy technology, which is applied in the field of alloy components and their preparation, can solve problems such as composition segregation deterioration, alloy components are prone to porosity, and high-entropy alloy materials have difficulty in expressing mechanical properties, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

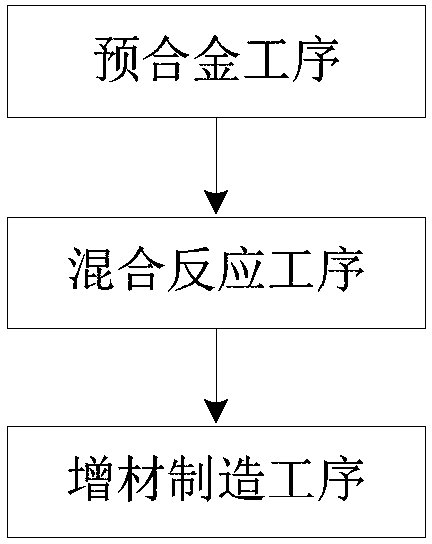

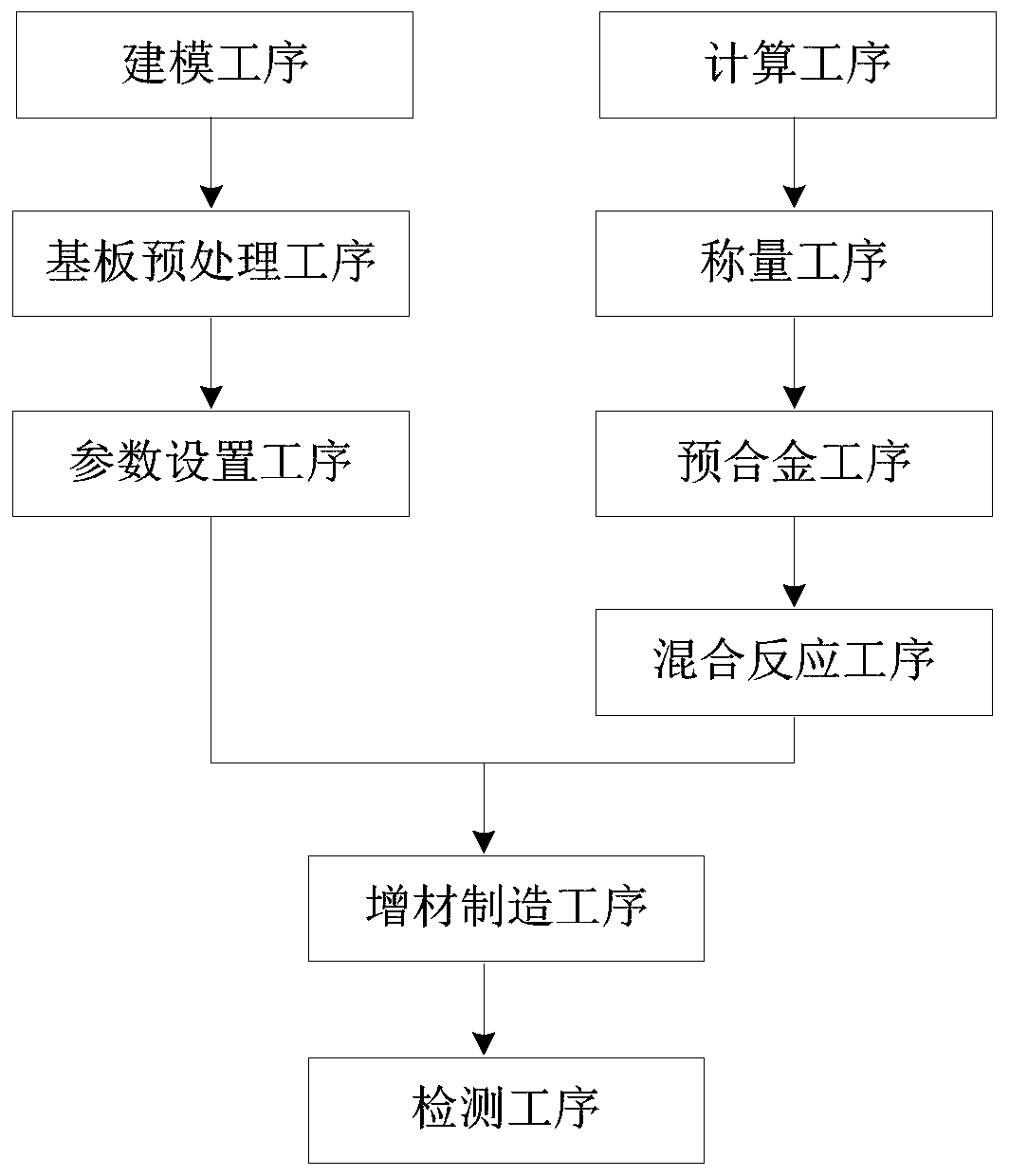

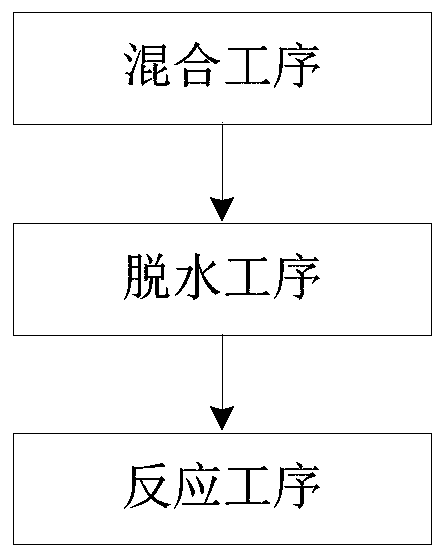

[0054] Such as figure 1 As shown, the preparation method of the alloy component involved in this embodiment may include the following steps: a pre-alloying process, performing a pre-alloying treatment on the high-entropy alloy raw material to obtain a pre-alloyed high-entropy alloy; a mixing reaction process, mixing and preparing Composite powders of nanotubes, carbon nanofibers, rare earth nanoparticles, and the pre-alloyed high-entropy alloy; the additive manufacturing process uses lasers to locally heat and melt the composite powders, and deposits and solidifies layer by layer to obtain alloy components.

[0055] In this embodiment, combined with the additive manufacturing process (such as 3D printing), the composite powder formed by carbon nanotubes, carbon nanofibers, rare earth nanoparticles and high-entropy alloys is heated and melted by laser and deposited layer by layer to form alloy components. Because the additive manufacturing process is not limited by mold manufac...

Embodiment 1

[0070] Laser-assisted additive manufacturing of high-entropy alloy marine propeller blades with a maximum length of 800mm, the process specifically includes the following steps:

[0071] Step 1: Use CAD software to make three-dimensional modeling of propeller blades, then use CAM software to plan the laser scanning path of each layer, and finally form the processing path program of the entire part, and input the program into the LAAM platform control software;

[0072] Step 2: Based on the calculation results of the thermodynamic software, the atomic percentage expression of the high-entropy alloy composition is designed as Fe 20 co 20 Ni 20 Nb 15 Ta 10 Cr 5 Zr 10 , convert the atomic percentages of Fe, Co, Ni, Nb, Ta, Cr, Zr elements into mass ratios and weigh the powders. The purity of the powders must reach more than 99.9%. Controlled within the range of 45μm to 105μm;

[0073] Step 3: Put the weighed Fe, Co, Ni, Nb, Ta, Cr, Zr element powders into a planetary high-e...

Embodiment 2

[0078] Laser-assisted additive manufacturing of high-entropy alloy marine diesel engine connecting rods with a maximum length of 1000mm, the process specifically includes the following steps:

[0079] Step 1: Use CAD software to model the diesel engine connecting rod in 3D, then use CAM software to plan the laser scanning path of each layer, and finally form the processing path program of the entire part, and input the program into the control software of the LAAM platform;

[0080] Step 2: Based on the calculation results of the thermodynamic software, the atomic percentage expression of the high-entropy alloy composition is designed as Fe 16 co 16 Ni 16 Nb 18 Ta 12 Cr 6 V 8 Zr 8 , convert the atomic percentages of Fe, Co, Ni, Nb, Ta, Cr, V, Zr elements into mass ratios and weigh the powders. The purity of the powders must reach 99.9%. The particle size is controlled within the range of 45μm to 105μm;

[0081] Step 3: Put the weighed Fe, Co, Ni, Nb, Ta, Cr, V, Zr elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com