High-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite material, and preparation method thereof

A technology of flame-retardant polyester and composite materials, applied in the field of polyester materials for charging piles, to achieve the effects of improving stability, high temperature resistance and high humidity resistance, and improving processing stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

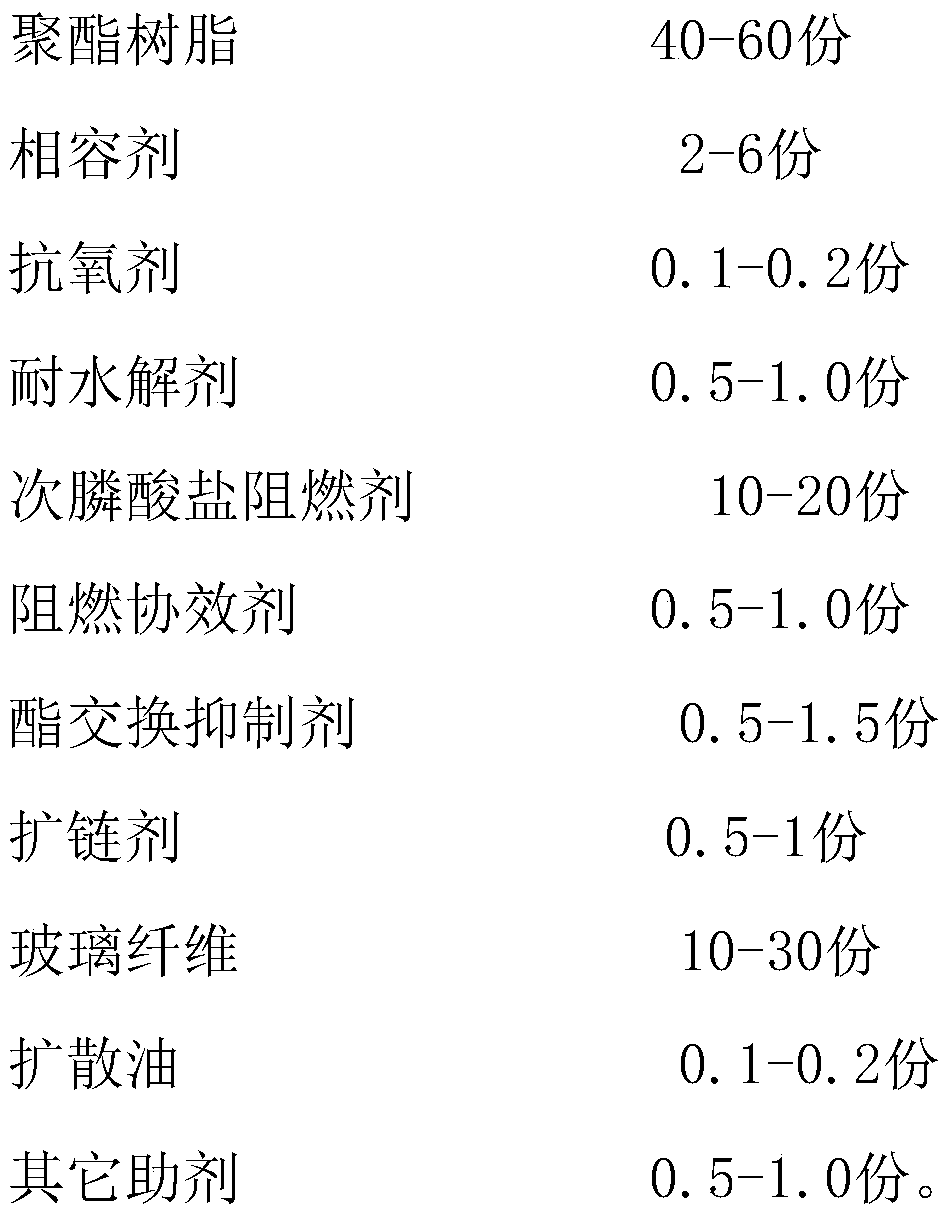

[0035] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0036]

[0037]

[0038] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 2:1. The intrinsic viscosity of polybutylene terephthalate is 0.9 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 1.1 dL / g.

[0039] The compatibilizer is a mixture of glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:1.5, and the relative The molecular weight is 8.5×10 4 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is acrylic acid-styrene-glycidyl methacrylate copolymer.

[0040] The antioxidant is formed by mixing a hindered phenolic primary antioxidant and a sulfide se...

Embodiment 2

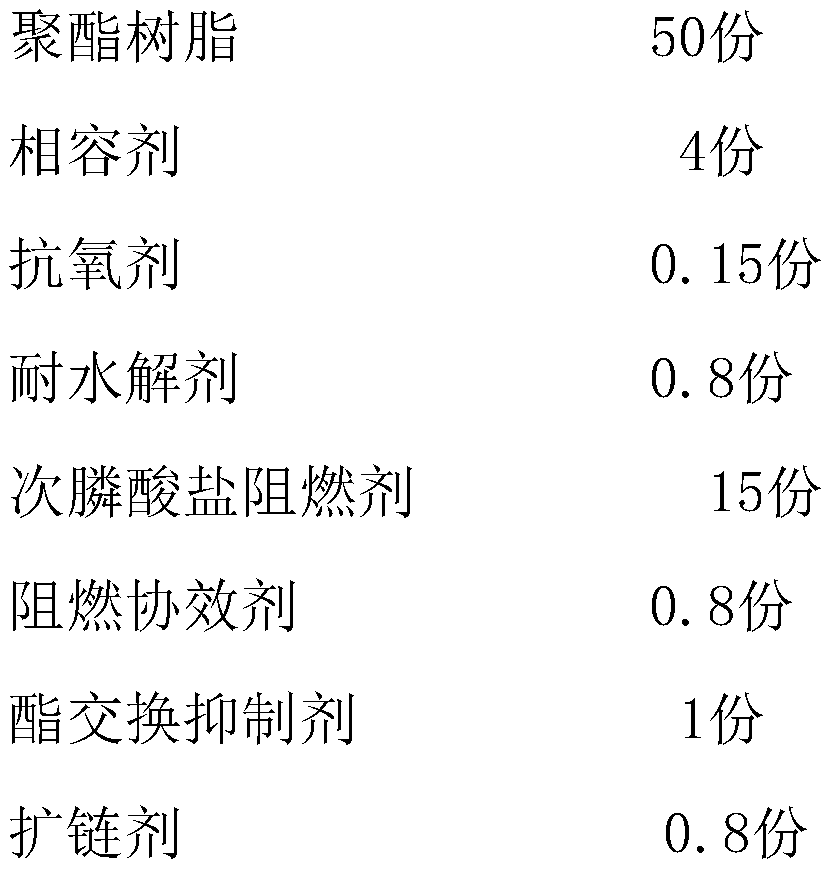

[0052] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0053]

[0054]

[0055] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 3:1. The intrinsic viscosity of polybutylene terephthalate is 0.7 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 1.2 dL / g.

[0056] The compatibilizer is formed by mixing glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:1. Molecular weight at 5×10 4 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is a methacrylic acid-styrene-glycidyl methacrylate copolymer.

[0057] The antioxidant is formed by mixing a hindered phenolic primary antioxidant and a sulfide secondary antioxi...

Embodiment 3

[0069] A high-temperature and high-humidity-resistant halogen-free flame-retardant polyester composite material, comprising the following raw materials in parts by weight:

[0070]

[0071] The polyester resin is formed by mixing polybutylene terephthalate and polyethylene terephthalate at a weight ratio of 1:1. The intrinsic viscosity of polybutylene terephthalate is 1.2 dL / g, and the intrinsic viscosity of polyethylene terephthalate is 0.7 dL / g.

[0072] The compatibilizer is formed by mixing glycidyl methacrylate grafted polyolefin elastomer and styrene-acrylonitrile-glycidyl methacrylate copolymer in a weight ratio of 3:2, and the relative Molecular weight at 1×10 5 . The chain extender is an acrylic-styrene copolymer containing epoxy groups; the acrylic-styrene copolymer containing epoxy groups is acrylic acid-styrene-glycidyl methacrylate copolymer and methyl Acrylic acid-styrene-glycidyl methacrylate copolymer is mixed at a weight ratio of 1:1.

[0073] The antio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com